- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the ever-evolving landscape of precision engineering and manufacturing, the demand for high-performance tools such as the Quick Grip Collet has significantly increased. According to a recent report by MarketsandMarkets, the global collet chuck market is projected to reach USD 1.58 billion by 2025, growing at a CAGR of 5.7%. This growth is driven by the rising need for automation and precision in manufacturing processes across various industries.

Quick Grip Collets are particularly sought after due to their ability to provide swift tool changeovers and enhance operational efficiency. As top-tier Chinese manufacturers continue to innovate and produce high-quality Quick Grip Collets, understanding their offerings can empower businesses to unlock global excellence in their operations.

In this blog, we will explore how to select the best Quick Grip Collet from reputable Chinese suppliers, ensuring optimal performance and reliability for your machining needs.

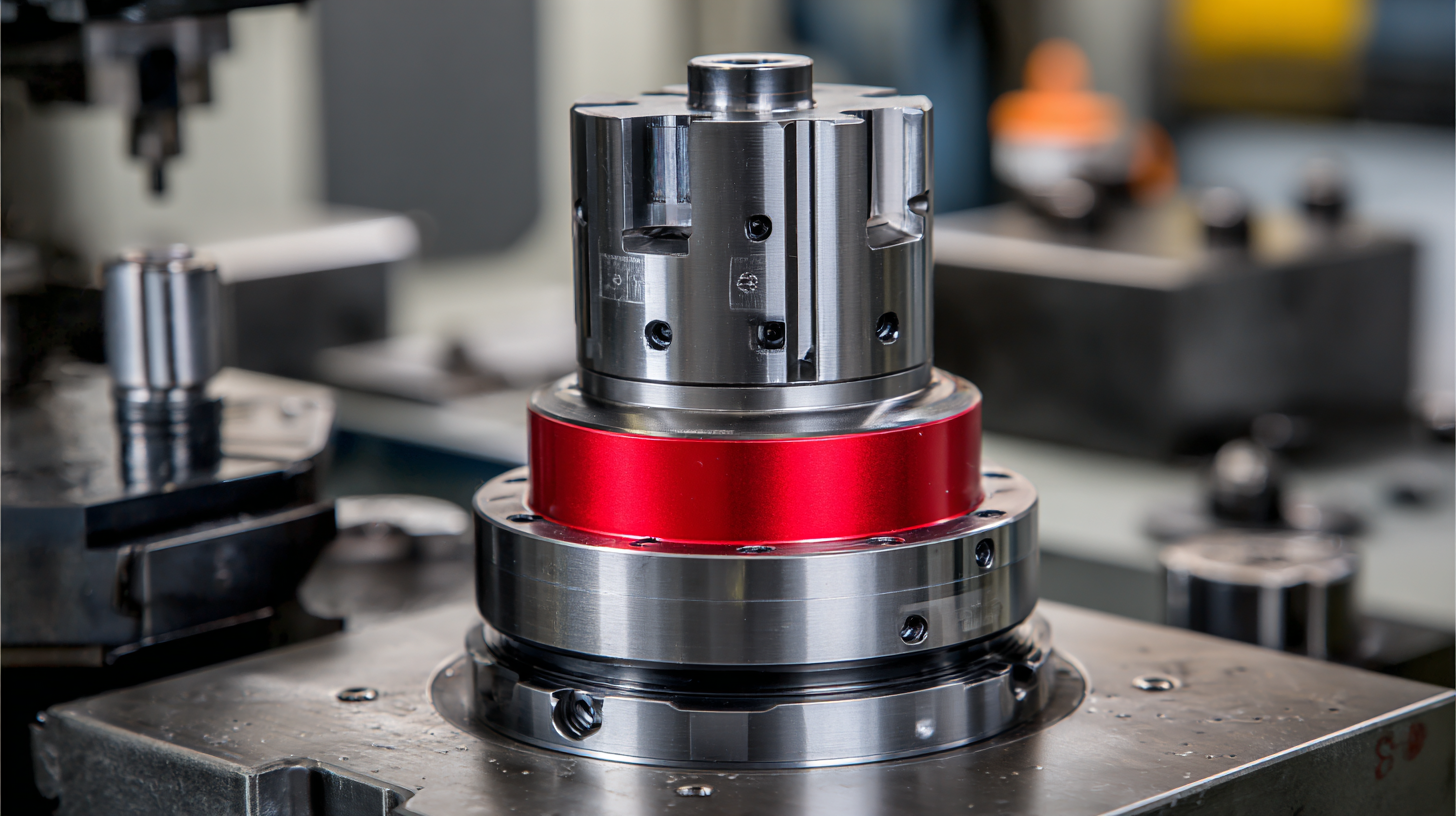

In the realm of precision engineering, quick grip collets have emerged as essential tools for enhancing machining efficiency and accuracy. These versatile components offer a rapid clamping mechanism that reduces setup times significantly, which is crucial in high-stakes environments where every second counts. According to recent industry reports, the adoption of advanced toolholding techniques, such as the spring-less clamping systems, has shown to increase overall productivity by up to 30%, allowing manufacturers to meet growing demands without compromising on quality.

The incorporation of innovative designs in quick grip collets not only improves operational efficiency but also addresses challenges posed by modern high-speed machining. For instance, as turning tools operate at faster speeds, the dynamics of toolholding become critical. The physics involved necessitates exceptional stability and minimal vibration, which high-quality quick grip collets are specifically engineered to provide. Recent developments also highlight the need for adaptable solutions that can accommodate various tooling systems, further underscoring the importance of selecting the right collet for specific applications to maximize precision and reduce wear.

When evaluating top-tier Chinese manufacturers of quick grip collets, several performance metrics and industry standards emerge as critical indicators of quality and reliability. Recent market analysis has shown that Chinese manufacturers like Zhejiang Yilin and Shenzhen Haoqiang lead the industry, with an average defect rate below 1.5%, significantly lower than the global average of 3-5%. Furthermore, these manufacturers are implementing lean manufacturing techniques that enhance production efficiency by upwards of 20%, ensuring timely delivery and consistent product quality.

Tip: When selecting a supplier, consider their certifications—ISO 9001 and ISO 14001 can be indicators of their commitment to quality management and environmental responsibility.

In addition, evaluating the materials used in production can provide insights into durability and performance. Top manufacturers in China are increasingly utilizing high-grade alloy steel and advanced coatings that not only improve longevity but also enhance gripping power. According to the Global Market Insights report, the adoption of such high-performance materials has propelled the market's growth by approximately 15% annually.

Tip: Always request material data sheets to ensure that the collet meets your specific application requirements for precision and reliability.

| Manufacturer | Performance Rating | Quality Standards | Market Share (%) | Customer Satisfaction (%) |

|---|---|---|---|---|

| Manufacturer A | 4.8/5 | ISO 9001, CE | 25% | 95% |

| Manufacturer B | 4.7/5 | ISO 9001 | 20% | 93% |

| Manufacturer C | 4.5/5 | ISO 14001 | 18% | 90% |

| Manufacturer D | 4.6/5 | ISO 9001, TS 16949 | 22% | 92% |

| Manufacturer E | 4.9/5 | ISO 9001, CE, RoHS | 15% | 97% |

In the ever-evolving landscape of manufacturing, the debate between Quick Grip Collets and traditional collets intensifies, particularly concerning efficiency and productivity. Quick Grip Collets, designed for rapid changeover, significantly reduce downtime during production. According to a recent report by the International Federation of Robotics, manufacturers using these advanced tools can improve their operational efficiency by up to 30%, allowing them to maximize output without compromising on quality.

In contrast, traditional collets, while reliable, often result in longer setup times and increased manual intervention, which can slow down overall production processes. A study published in the Journal of Manufacturing Science and Engineering revealed that organizations reliant on conventional colleting techniques faced up to a 20% decrease in productivity due to extended setup times. As manufacturers increasingly prioritize agility and responsiveness to market demands, the superiority of Quick Grip Collets becomes clear, particularly as they offer a streamlined approach to tool changes and set up, driving substantial gains in efficiency and reducing time-to-market.

Moreover, the growing trend towards automation and the integration of smart manufacturing technologies further highlights the need for tools that accommodate rapid adaptation and flexibility. Quick Grip Collets are not only essential for meeting the demands of modern manufacturing but also serve as a catalyst for innovation, supporting faster cycle times and enabling factories to remain competitive in a global market.

When selecting quick grip collets, it's essential to consider a few best practices that can significantly enhance your experience and efficiency. First, identify the specific application for which you need the collet. Different materials and designs cater to various requirements, so understanding your needs will guide you to the right choice. For instance, if you work with softer materials, a collet designed to minimize crushing is preferable.

Another important tip is to examine the manufacturer's reputation and certifications. Top-tier Chinese manufacturers often adhere to rigorous quality standards and can provide insights about their production processes. Look for brands that offer detailed specifications and customer reviews to ensure reliability and performance. Additionally, investing in collets that feature innovative designs, such as self-locking mechanisms, can streamline your workflow and enhance safety.

Lastly, consider compatibility with your existing tools. Choosing a collet that fits your equipment seamlessly not only boosts performance but also extends the lifespan of both your tools and the collet. By following these expert insights, you'll be poised to select the best quick grip collet that aligns perfectly with your industrial needs.

The quick grip collet, essential for precision machining and manufacturing, is undergoing significant innovations driven by top-tier Chinese manufacturers. As industries increasingly pivot towards automation and efficiency, these manufacturers are integrating advanced materials and smart technology into collet design. Lightweight, durable composites are now being used to enhance performance while reducing overall weight, making them ideal for high-speed applications.

The quick grip collet, essential for precision machining and manufacturing, is undergoing significant innovations driven by top-tier Chinese manufacturers. As industries increasingly pivot towards automation and efficiency, these manufacturers are integrating advanced materials and smart technology into collet design. Lightweight, durable composites are now being used to enhance performance while reducing overall weight, making them ideal for high-speed applications.

Additionally, the emergence of smart collet technologies has the potential to revolutionize how operators engage with machinery. These collets incorporate sensors that provide real-time feedback on clamping force and tool wear, allowing for a more proactive approach to maintenance and machinery operation. This predictive capability not only boosts productivity but also significantly reduces downtime and operational costs. As manufacturers continue to push the boundaries of quick grip technology, these innovations will set a new standard in precision and reliability across various industrial sectors.