- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In today's manufacturing landscape, the demand for precision and customization is at an all-time high, with the global custom steel machining market projected to reach USD 8.05 billion by 2025, growing at a CAGR of 6.2% (Smithers, 2021). Custom steel machining offers businesses the ability to create tailor-made components that meet specific operational requirements, thus enhancing efficiency and reducing waste. With advancements in CNC technology and a growing emphasis on sustainability, companies are increasingly turning to custom solutions to remain competitive.

This comprehensive guide will delve into the various facets of custom steel machining, providing essential tips and strategies to leverage this process for your business success. Whether you're a seasoned manufacturer or a newcomer to the industry, understanding the nuances of custom steel machining is critical to thriving in today's market.

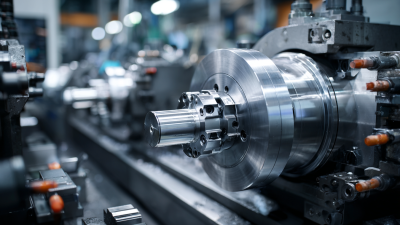

Custom steel machining is a vital process for businesses seeking efficiency and precision in their production. At its core, this manufacturing technique involves shaping steel components to meet specific requirements, which can significantly enhance product performance. Understanding the fundamentals of custom steel machining can empower businesses to optimize their production methods, allowing for greater customization and flexibility in meeting market demands.

As industries evolve, the incorporation of advanced technologies like artificial intelligence into manufacturing processes is becoming increasingly important. AI applications can streamline operations, improve quality control, and even predict maintenance needs, further elevating the advantages of custom steel machining. Additionally, the rise of additive manufacturing presents exciting opportunities for businesses to innovate. By leveraging techniques such as 3D printing, companies can create complex designs with less material waste, enhancing both functionality and sustainability. Embracing these technologies can position your business at the forefront of the competitive landscape, driving success through modernization and efficiency.

This bar chart illustrates the relationship between investment in custom steel machining and business performance indicators such as productivity, product quality, and customer satisfaction. The data reflects how increased investment can lead to greater success across these key metrics.

When selecting a custom steel machining partner, several key factors must be taken into account to ensure your business's success. First, consider the technology and equipment they use. According to a report by Grand View Research, the global CNC machine market size is expected to reach USD 100.8 billion by 2025, emphasizing the importance of partnering with a manufacturer that employs the latest machining technologies. Advanced machinery not only enhances precision but also increases efficiency and quality, resulting in reduced production time and costs.

Another critical aspect to evaluate is the partner’s experience and expertise in your specific industry. A study by MarketsandMarkets indicates that the demand for custom machining services is projected to grow at a CAGR of 6.9% from 2020 to 2025, underlining the need for skilled professionals in this field. A partner with a strong track record in your sector will better understand the nuances and regulations that impact production. Furthermore, consider their commitment to customer service and support, as ongoing communication and responsiveness can significantly enhance project outcomes and foster a long-term partnership.

In today's competitive manufacturing landscape, enhancing efficiency in steel machining processes is essential for business success. Innovative techniques such as advanced automation, precision tooling, and data-driven decision-making can significantly streamline operations. Embracing automation not only reduces human error but also increases production rates by allowing for continuous operation. Technologies like CNC (Computer Numerical Control) machines enable businesses to achieve precise cuts and intricate designs with minimal manual intervention, ensuring consistent quality across all products.

Moreover, adopting smart manufacturing practices can further optimize steel machining workflows. Implementing IoT (Internet of Things) devices helps monitor equipment performance in real-time, predicting maintenance needs and reducing downtime. This proactive approach leads to improved productivity and cost savings. Additionally, utilizing advanced software for scheduling and resource allocation can create a more organized workflow, ensuring that materials are available when needed while minimizing excess inventory. By integrating these innovative techniques, businesses can not only enhance their steel machining processes but also position themselves for long-term success in a rapidly evolving market.

| Process Type | Efficiency (%) | Lead Time (Days) | Cost ($) | Material Used |

|---|---|---|---|---|

| CNC Milling | 90 | 5 | 2000 | Steel Alloy |

| Laser Cutting | 85 | 3 | 1500 | Stainless Steel |

| Welding | 88 | 4 | 1800 | Carbon Steel |

| Bending | 80 | 6 | 1700 | Alloy Steel |

| Finishing | 75 | 2 | 1600 | Mild Steel |

In today's competitive landscape, leveraging cost-effective strategies for custom steel machining is crucial for driving business success. According to a market research study from Custom Market Insights, the demand for CNC metal machining is on the rise, indicating a strong growth trajectory in the manufacturing sector. The global CNC machine market is expected to grow at a CAGR of 5.5%, projected to reach a value of $77 billion by 2024. This growth reflects the increasing reliance on precision machining to meet production demands efficiently.

To maximize cost-effectiveness in operations, companies should evaluate machining costs meticulously. This involves considering setup costs, tool use expenses influenced by cutting parameters, and the amortization of machinery linked to production volume. Implementing an effective toolpath model can enhance tool utilization and efficiency, allowing businesses to employ longer milling tool flutes, optimizing the machining process. Furthermore, emerging trends in Industry 4.0 technologies promise to further drive down costs and improve sustainability, providing an avenue for manufacturers to innovate while maintaining competitive pricing.

As the manufacturing landscape evolves, the importance of custom steel machining becomes increasingly evident for businesses aiming to stay ahead. The growth of humanoid robotics illustrates a key trend: the rising significance of components such as screws, which represent about 20% of overall production costs. This shift not only emphasizes the need for precision machining in the production of critical hardware but also signals a trend where efficiency and quality take center stage in the supply chain.

Businesses must adapt to these developments by investing in advanced machining technologies that enhance production capabilities. Techniques like CNC machining offer unparalleled precision, allowing for the creation of complex components tailored to specific requirements in robotics and other sectors. As companies navigate these changes, understanding market demands and trends will lead to more informed decisions, optimizing both product quality and profitability in an increasingly competitive environment.