- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

When it comes to maintaining a clean and safe industrial environment, choosing the right oil mist filter is crucial. An effective oil mist filter not only enhances air quality but also protects machinery from harmful contaminants. With the increasing awareness of health and safety standards, the demand for high-quality oil mist filters has surged, making it essential for buyers to make informed decisions. If you are looking to invest in an oil mist filter, knowing what to consider can streamline your purchasing process and ensure that you find a product that suits your specific needs.

In this guide, we will provide you with the top 10 tips for making an informed oil mist filter buy. From understanding the types of filters available to evaluating their efficiency and maintenance requirements, these tips will serve as a roadmap for navigating the complexities of the purchasing process. Environmental considerations, budget constraints, and specific application requirements will also be discussed, empowering you to select the best oil mist filter for your unique scenario. Whether you are a seasoned professional or a newcomer to industrial equipment, these essential insights will help you secure a filter that not only meets but exceeds your expectations.

Oil mist filters play a crucial role in industrial applications, particularly in environments where metalworking processes generate significant amounts of oil mist. According to a study by the National Institute for Occupational Safety and Health (NIOSH), exposure to metalworking fluids can lead to various health issues, including respiratory disorders and skin irritation. Therefore, incorporating effective oil mist filtration systems is essential for maintaining a safe workplace and ensuring compliance with health regulations.

Furthermore, the global oil mist separator market is projected to grow significantly, with an anticipated compound annual growth rate (CAGR) of approximately 7% over the next five years, as reported by Research and Markets. This growth is driven by increased awareness of employee health and safety, coupled with stringent environmental regulations. Industries such as automotive, aerospace, and machining are increasingly adopting oil mist filters to capture harmful particles and reduce overall air contamination. A high-quality oil mist filter can capture up to 99% of mist and smoke particles, thereby improving air quality and reducing maintenance costs associated with equipment corrosion and contamination.

| Tip Number | Tip Description | Considerations |

|---|---|---|

| 1 | Assess the type of machining processes | Understand the types of operations generating oil mist. |

| 2 | Evaluate filter efficiency ratings | Check for filters with high capture rates. |

| 3 | Consider filter size and shape | Ensure it fits your existing equipment. |

| 4 | Look for maintenance requirements | Less maintenance can mean lower operational costs. |

| 5 | Assess airflow requirements | Ensure the filter supports the air volume needed. |

| 6 | Consider noise levels | Lower noise levels improve work environment. |

| 7 | Review energy consumption | Energy-efficient models reduce operating costs. |

| 8 | Look for certifications and standards | Compliant filters ensure reliability and safety. |

| 9 | Read user reviews and recommendations | Feedback can highlight pitfalls and advantages. |

| 10 | Consult with industry experts | Expert opinions can guide your filtering decisions. |

When considering the purchase of an oil mist filter, it is essential to focus on key features that meet your specific operational needs. One critical feature is the filter's efficiency, which is typically expressed as a percentage of mist removal. According to a report by the Institute of Clean Air Companies, high-performance filters can achieve mist removal efficiencies exceeding 99%, significantly reducing airborne contaminants in work environments. This efficiency not only helps in maintaining air quality but also contributes to compliance with health and safety regulations, minimizing the risk of occupational exposure to harmful mist.

Another vital element to consider is the filter's airflow capacity, which determines how much air the system can process without compromising efficiency. Industries with high machining processes often require filters capable of handling substantial airflow while maintaining performance. Data from industry analysis indicates that filters with adjustable airflow mechanisms are particularly advantageous, as they allow users to tailor the system to varying operational conditions, providing both versatility and cost savings through optimized energy consumption. Additionally, the durability and maintenance requirements of the filter play a significant role in its overall effectiveness; choosing filters with robust construction can lead to lower long-term costs and reduced downtime for maintenance.

When evaluating different types of oil mist filters available in the market, it's essential to understand the various technologies and designs that cater to specific industrial needs. Oil mist filters primarily operate on the principle of capturing airborne oil particles generated during machining processes. The most common types include electrostatic filters, coalescing filters, and mechanical filters. Each of these types offers distinct advantages based on the application environment, efficiency requirements, and maintenance considerations.

Electrostatic filters are known for their ability to efficiently capture fine oil mist particles without significant energy consumption. They work by using an electric charge to attract and trap droplets, making them ideal for facilities that generate a high volume of mist. On the other hand, coalescing filters are effective in removing both parts of the oil mist and larger droplets by combining them into bigger droplets that can then be drained away. Mechanical filters, typically constructed from fibrous materials, work by physically trapping oil droplets and require regular cleaning or replacement to maintain efficiency. By examining these different options, buyers can choose a filter that aligns closely with their operational needs and environmental considerations.

When considering the purchase of an oil mist filter, understanding its cost-effectiveness is crucial for making an informed decision. The initial investment in an oil mist filter may seem significant, but it is essential to evaluate this cost against the potential savings it can generate in the long run. A well-selected filter can greatly reduce the frequency of machinery maintenance and the amount of wasted oil, leading to lower operational costs.

Additionally, by enhancing the efficiency of your equipment, you improve productivity and reduce the likelihood of costly downtime.

It's also important to consider the longevity and maintenance requirements of the filter. Some models may have higher upfront costs but require less frequent replacements and maintenance, resulting in a better overall financial outcome. Analyze the total cost of ownership, which includes purchase price, installation costs, energy consumption, and expected lifespan. By doing so, you ensure that your investment not only addresses your immediate needs but also aligns with your long-term operational and financial goals. Exploring options that offer extended warranties or service agreements can also add to the long-term value of your purchase.

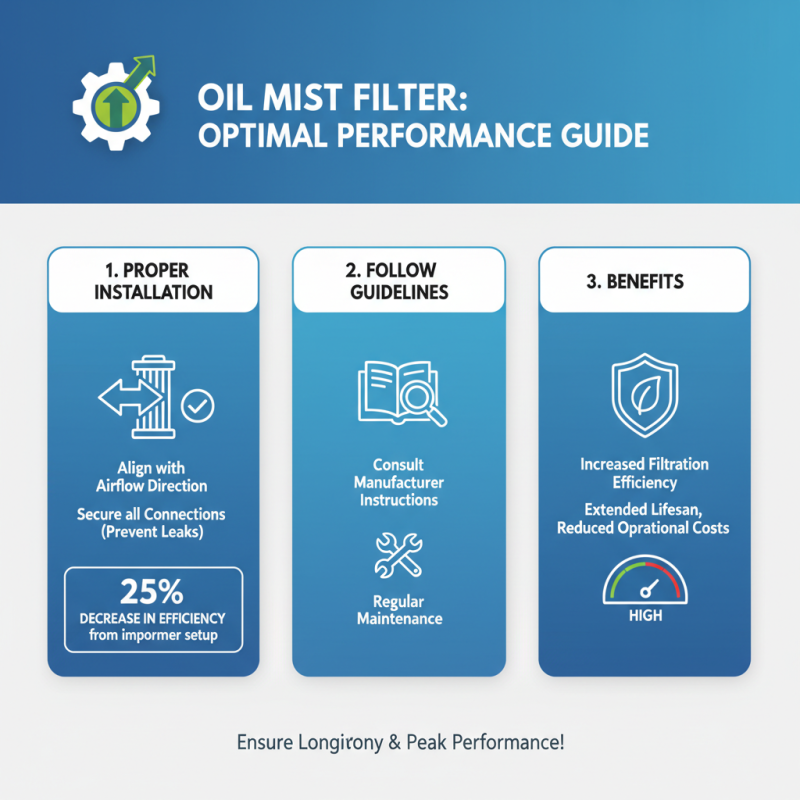

When selecting an oil mist filter, proper installation and maintenance are critical to ensuring optimal performance and longevity. Research indicates that improper installation can lead to a 25% decrease in filtration efficiency, making it essential to follow manufacturer guidelines closely. When installing the filter, ensure that it is positioned in alignment with the airflow direction to maximize its effectiveness. Moreover, securing all connections properly will prevent leaks, which can compromise performance and lead to increased operational costs.

Regular maintenance is equally vital for sustaining filter efficiency. According to industry reports, filters that are not cleaned or replaced regularly can accumulate up to 40% more particulate matter over time, significantly hampering their functionality. It is recommended to adhere to a maintenance schedule based on the specific usage and operating conditions of your machinery. This includes routine inspections for signs of wear and tear, as well as ensuring that the filter's collecting media is free from obstructions. By prioritizing effective installation and diligent maintenance, you can enhance the overall efficiency of your oil mist filtration system and minimize downtime, contributing to smoother operations and cost savings in the long run.