- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

Selecting the right tooling for lathe operations is crucial for optimizing machining efficiency and product quality in the manufacturing industry. According to a report by the National Tooling and Machining Association (NTMA), over 70% of manufacturers identified tooling as a significant factor influencing production costs and lead times. The proper selection of tooling for lathe can lead to an increase in operational efficiency by as much as 30%, while also improving the surface finish and dimensional accuracy of machined parts. As CNC technology advances, the complexity of tooling for lathe operations has also increased, making it essential for manufacturers to stay informed about new materials and designs. This guide aims to help professionals navigate the selection process by highlighting key considerations and best practices for choosing the ideal tooling for lathe operations to enhance productivity and maintain competitive edge in the industry.

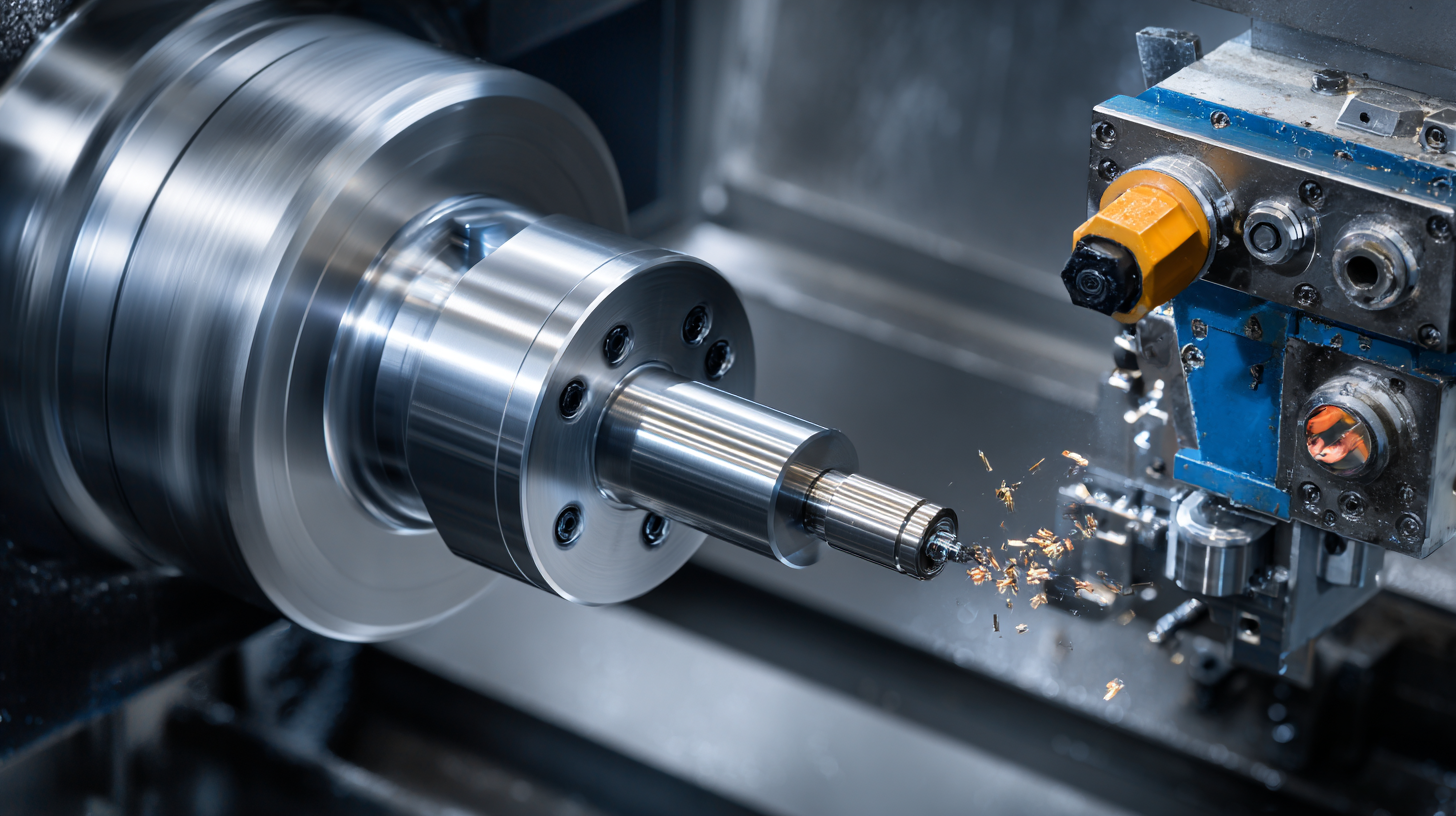

Selecting the right tooling for lathe operations requires a thorough understanding of several key factors that can significantly affect productivity and quality. The first crucial factor is the material of the workpiece. According to a 2021 report by the American Machinist, approximately 45% of machining failures are due to improper tooling choices based on material properties. For instance, high-speed steel tools are commonly used for softer metals, while carbide tools are preferred for harder materials due to their superior wear resistance and ability to withstand higher temperatures.

Another important consideration is the type of operation being performed. Whether it's turning, facing, or threading, each operation demands specific tooling characteristics. A study conducted by the National Institute of Standards and Technology (NIST) highlighted that using the wrong tool geometry could lead to a reduction in tool life by over 30%. Therefore, it is essential to match the tool's geometry with the intended application, taking into account factors such as cutting speed, feed rate, and depth of cut. Making informed decisions based on these key factors can lead to enhanced machining efficiency and reduced costs in the long run.

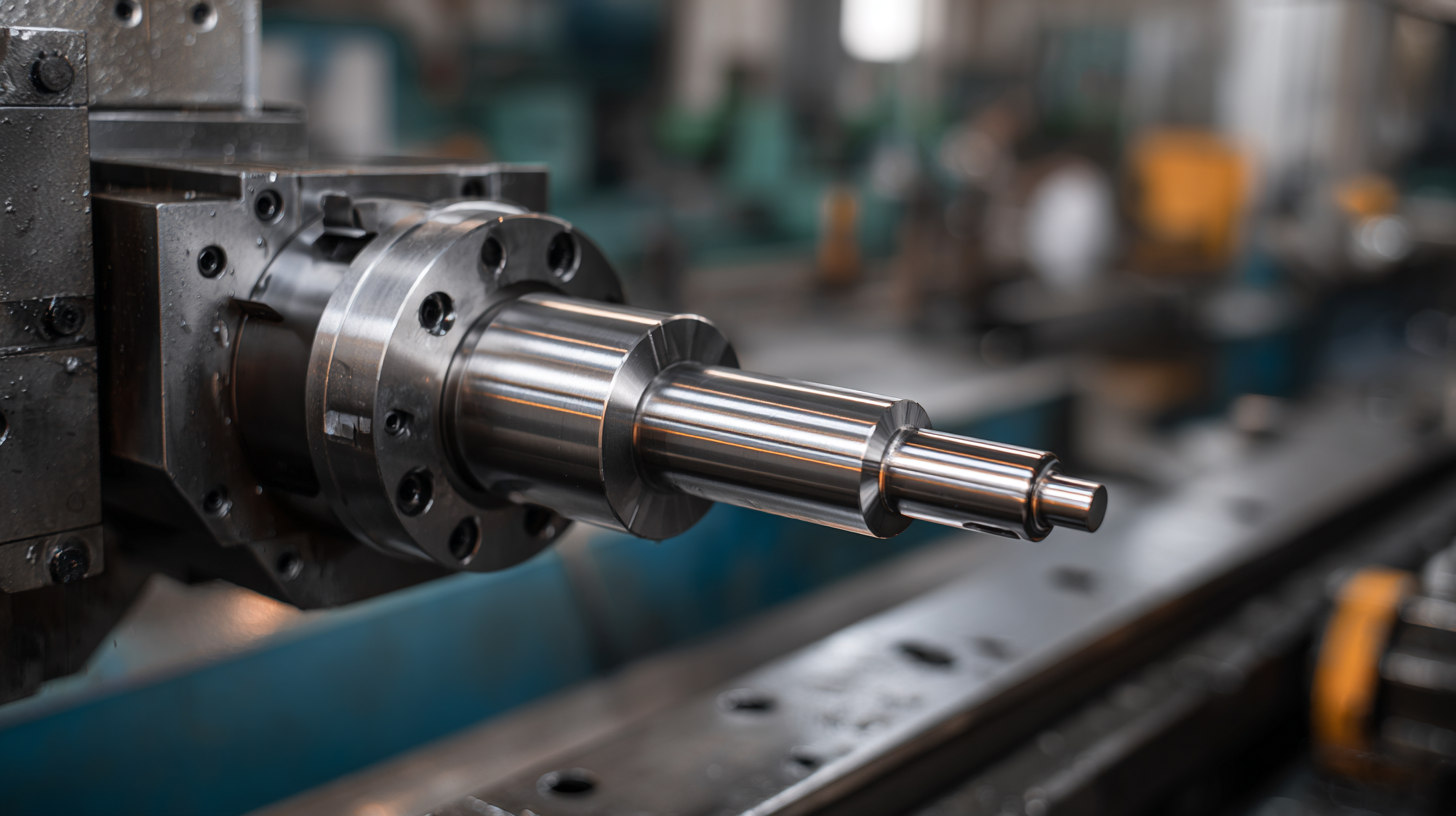

When selecting tooling for lathe operations, it's crucial to understand the different types of lathe tooling available, as each type is designed for specific applications. Common categories include turning tools, boring tools, threading tools, and parting tools, each offering distinct advantages based on the material being machined and the desired outcome. According to a report from Market Research Future, the global lathe machine market is expected to grow at a CAGR of 5% from 2021 to 2026, largely driven by advancements in tooling technology that enhance precision and efficiency.

Turning tools, often made from high-speed steel or carbide, are essential for shaping and finishing workpieces. A recent study by the Manufacturing Institute indicates that using carbide tooling can increase cutting speeds by up to 50% compared to high-speed steel, allowing manufacturers to optimize production time and material use. Boring tools, on the other hand, are specifically designed for enlarging holes, while threading tools are crucial for creating screw threads with a high degree of accuracy. Each tool type is integral to the overall efficiency and effectiveness of lathe operations, making informed selection essential for manufacturers aiming to improve productivity and reduce costs.

When selecting tooling for lathe operations, one of the most critical factors to consider is material compatibility. The effectiveness and longevity of tools are significantly influenced by the materials being machined. For example, tools designed for steel may not perform well with softer materials like aluminum, leading to premature wear or ineffective cutting. Conversely, using a tool intended for softer materials on harder metals can result in chipping or other damage. It’s essential to match the cutting tool material to the specific workpiece material to achieve optimal performance.

Additionally, the hardness and toughness of the materials involved play a pivotal role in this selection process. High-speed steel (HSS) tools are commonly used for general applications and work well with a range of materials due to their toughness. However, for machining harder materials, carbide inserts are often preferred because they can withstand higher temperatures and maintain their sharpness for longer periods. Evaluating these material characteristics ensures that the chosen tooling not only enhances productivity but also ensures safety and efficiency in the lathe operations. Understanding these compatibility dynamics is essential for achieving the best results in machining processes.

| Tooling Material | Compatible Workpieces | Cutting Speed (m/min) | Feed Rate (mm/rev) | Recommended Coolant |

|---|---|---|---|---|

| High-Speed Steel (HSS) | Mild Steel, Aluminum | 20-40 | 0.1-0.3 | Water Soluble |

| Carbide | Stainless Steel, High-Strength Alloys | 60-100 | 0.2-0.5 | Oil-Based |

| Cermet | Cast Iron, Advanced Composites | 40-80 | 0.15-0.4 | Minimum Quantity Lubrication |

| Ceramic | Glass, Hard Alloys | 100-200 | 0.1-0.3 | Dry Cutting |

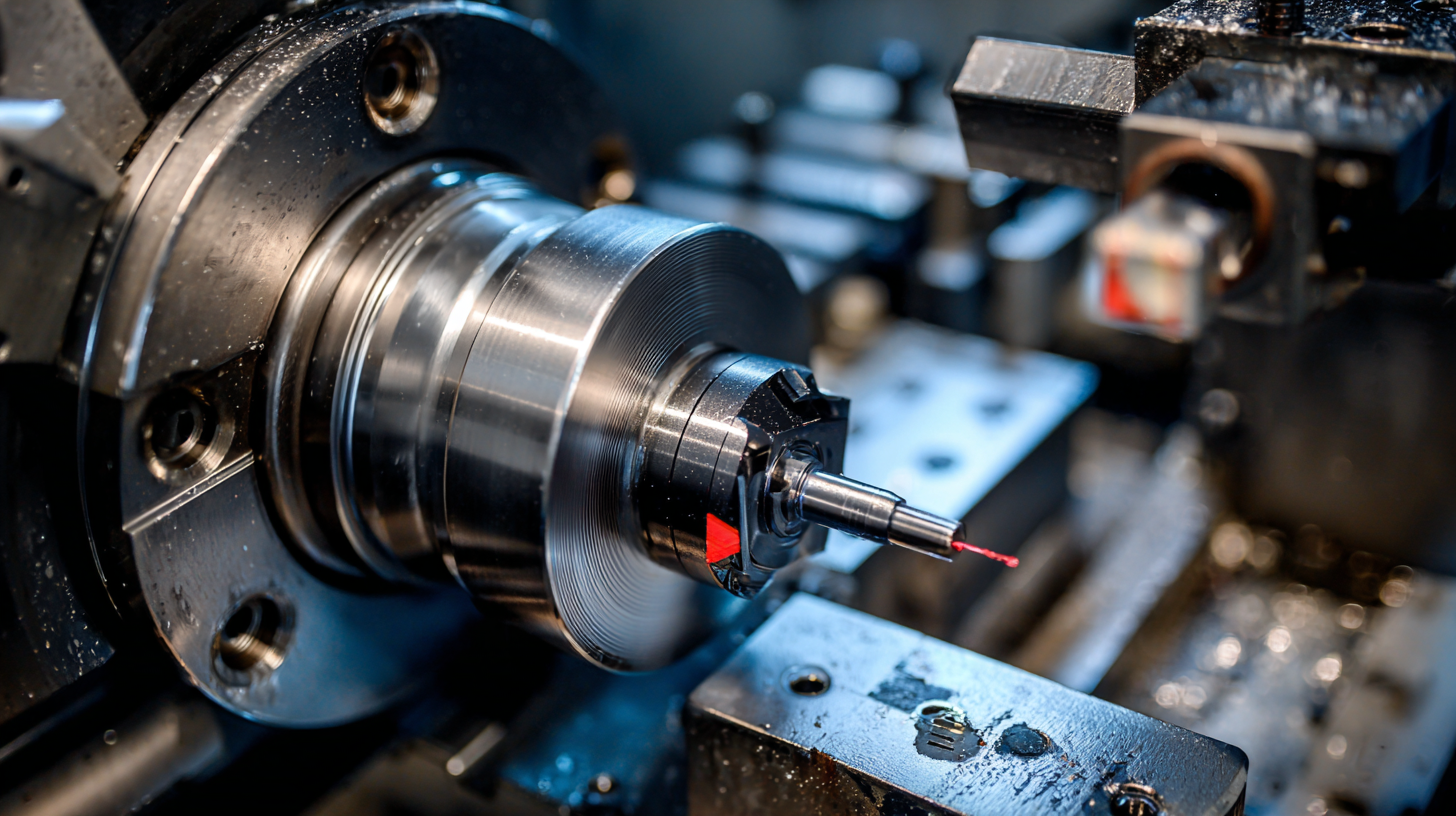

When selecting tooling for lathe operations, understanding tool geometry is crucial, as it significantly impacts performance and productivity. According to a report by the Cutting Tool Engineering Association, improper tool geometry can lead to as much as a 15% increase in machining time and result in higher tool wear rates. Key geometrical features such as rake angle, clearance angle, and cutting edge geometry all play pivotal roles in enhancing machining efficiency, ensuring optimal cutting action, and minimizing vibrations.

Tip: Always consider the material being machined when assessing tool geometry. For harder materials, tools with a greater rake angle tend to reduce cutting forces and improve chip flow.

Moreover, different lathe operations—such as turning, facing, and boring—may require specific tool geometries for optimal results. For instance, a positive rake angle is often preferred in turning operations to enhance chip removal and reduce cutting forces. The right geometry not only improves surface finish but also extends tool life, leading to savings in production costs.

Tip: Regularly review and adapt your tooling strategy based on performance metrics to ensure continued efficiency in your lathe operations.

When maintaining and replacing tooling for lathe operations, it's crucial to adopt efficient practices to ensure optimal performance. Regular inspections of tools can help identify wear and tear early, preventing unexpected downtimes. Implementing a routine schedule for maintenance checks can aid in prolonging the lifespan of your lathe tooling, thus improving overall productivity.

Tips for maintaining your lathe tooling effectively include ensuring proper storage to prevent damage from environmental factors, such as moisture or extreme temperatures. Utilizing tool holders that minimize vibration can not only enhance the longevity of the tooling but also improve the quality of your work. Additionally, keeping all cutting tools sharp and clean will facilitate smoother operations and reduce scrap production.

When it comes to replacing tooling, consider investing in advanced materials that provide better durability and efficiency. This not only results in lower operational costs but also contributes to a greener workspace as the frequency of replacements decreases. Integrating smart technology like monitoring systems can further optimize usage patterns, allowing for timely replacements before significant wear occurs.