- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

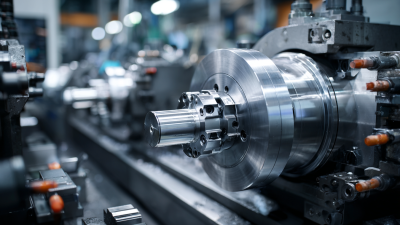

In today's industrial landscape, maximizing operational efficiency while ensuring worker safety is paramount. According to a report by the Occupational Safety and Health Administration (OSHA), exposure to oil mist can lead to severe health issues, including respiratory problems and skin irritations, which affect both productivity and employee well-being. An effective solution to mitigate these risks is the implementation of an Oil Mist Purifier, which can capture and remove harmful airborne particulates from the manufacturing environment. Studies indicate that factories deploying such systems can achieve a reduction in airborne pollutants by up to 90%, significantly improving air quality. Furthermore, with increasing regulatory pressures around workplace safety and environmental impact, investing in an Oil Mist Purifier not only enhances compliance but also promotes a healthier workplace, ultimately leading to better operational performance and lower costs associated with health-related absences.

The environmental benefits of using oil mist purifiers in industrial settings are significant and multifaceted. Firstly, these purifiers effectively capture and eliminate airborne oil mist, which is a common byproduct of various manufacturing processes. By reducing the number of harmful particles released into the atmosphere, factories can significantly lower their overall emissions and contribute to cleaner air quality. This is particularly important in regions where industrial activities contribute to high levels of pollution, helping to protect the health of workers and nearby residents.

Moreover, employing oil mist purifiers can lead to a reduction in waste. Traditional methods of handling oil waste can result in spillage and contamination of soil and water resources. With efficient purifiers, the collected oil mist can often be recycled and reused, minimizing the environmental footprint of industrial operations. Not only does this promote sustainability, but it also supports a circular economy by transforming what would be waste into a valuable resource. Consequently, integrating oil mist purifiers in factories not only aligns with environmental regulations but also enhances corporate responsibility, paving the way for a more sustainable industrial future.

In industrial settings, the presence of oil mist is a significant concern that can compromise workplace safety. Oil mist purifiers play a critical role in mitigating this risk by effectively removing airborne oil particles, ensuring a cleaner environment for workers. This not only helps in maintaining a healthier workspace but also reduces the likelihood of accidents caused by slips or falls due to oily residues on surfaces.

To enhance workplace safety, it's essential for factory managers to regularly maintain and check oil mist purifiers. Implementing a routine cleaning schedule ensures that the filters are performing optimally and that the air quality remains at safe levels. Consider also conducting periodic air quality assessments to track the effectiveness of the purification system over time.

Moreover, educating employees about the importance of oil mist purifiers can foster a culture of safety and awareness. Regular training sessions can help workers understand how these systems work and the benefits they provide. Encouraging workers to report any signs of oil mist or malfunctioning equipment promptly can further enhance safety and operational efficiency.

| Reason | Description | Impact on Workplace Safety | Long-Term Benefits |

|---|---|---|---|

| Reduces Airborne Contaminants | Removes oil mist and other contaminants from the air. | Improves air quality, decreasing respiratory issues. | Lower health-related costs and absenteeism. |

| Enhances Equipment Longevity | Prevents oil build-up on machinery. | Reduces risk of equipment failure. | Increased efficiency and reduced maintenance costs. |

| Compliance with Regulations | Helps meet environmental and workplace safety standards. | Reduces legal and compliance risks. | Avoidance of penalties and fines. |

| Improves Employee Morale | Creates a cleaner and healthier work environment. | Boosts employee satisfaction and productivity. | Better retention rates and lower turnover costs. |

| Enhanced Visibility | Reduces mist that obscures vision in work areas. | Minimizes accidents caused by poor visibility. | Safe working conditions enhance operational capacity. |

| Cost-Effective Solution | Reduces costs related to health issues and equipment damage. | Lower operational risks lead to safer environments. | Incorporating technology saves money in the long run. |

| Environmental Benefits | Reduces harmful emissions into the atmosphere. | Supports corporate social responsibility initiatives. | Positively impacts company reputation and brand image. |

Investing in oil mist purification technology is not just an operational upgrade; it's a strategic move towards significant cost savings and efficiency improvements. Factories often grapple with the challenges of oil mist in the workplace, which can lead to equipment wear, increased maintenance costs, and a hazardous environment for employees. By implementing an oil mist purifier, manufacturers can effectively reduce airborne contaminants, thereby extending the lifespan of machinery and minimizing downtime associated with repairs. This leads to fewer unplanned maintenance costs and a more consistent production schedule, which directly impacts the bottom line.

Moreover, oil mist purifiers enhance overall workplace efficiency by creating a cleaner environment. A reduction in particulate matter means better air quality, which improves employee health and productivity. Workers in a clean and safe environment are more likely to achieve higher levels of performance and lower absenteeism rates. Additionally, with less reliance on frequent cleaning schedules and reduced health hazards, operational efficiency is further bolstered. In this way, investing in oil mist technology is not only an environmental responsibility but also a sound financial decision that can yield substantial returns in productivity and health.

In today's industrial landscape, regulatory compliance is not just a necessity; it’s a fundamental aspect of sustainability and operational excellence.

Oil mist purifiers serve as a practical solution for factories aiming to meet environmental standards while improving workplace safety. These devices efficiently capture and filter oil mist produced during machining processes, ensuring that harmful particles do not escape into the environment. By investing in oil mist purifiers, manufacturers can easily align their operations with government regulations, avoiding costly fines and enhancing their reputation in the industry.

Oil mist purifiers serve as a practical solution for factories aiming to meet environmental standards while improving workplace safety. These devices efficiently capture and filter oil mist produced during machining processes, ensuring that harmful particles do not escape into the environment. By investing in oil mist purifiers, manufacturers can easily align their operations with government regulations, avoiding costly fines and enhancing their reputation in the industry.

Moreover, the adoption of oil mist purifiers can significantly reduce emissions that contribute to air pollution. This proactive approach not only helps in complying with air quality regulations but also demonstrates a commitment to sustainability and corporate responsibility. As governments worldwide tighten regulations around emissions, having an efficient oil mist purification system can provide factories with a competitive edge. This not only safeguards the health of employees but also positions the business as a leader in environmental stewardship, ultimately leading to long-term benefits and stability in a market that increasingly values sustainable practices.

In today’s competitive manufacturing landscape, the use of oil mist solutions is essential for factories aiming to enhance their operational efficiency and maintain a clean working environment. Oil mist purifiers offer a significant advantage by capturing airborne oil mist and smoke, which is not only harmful to workers’ health but can also lead to costly machinery failures. According to industry reports, the global market for oil mist separators is projected to grow substantially, with a compound annual growth rate of approximately 6.2% from 2024 to 2030. This trend reflects an increasing recognition among manufacturers of the necessity to invest in pollution control technologies.

Moreover, the burgeoning electronic cigarette industry has further emphasized the importance of effective oil mist management. With around 95% of e-cigarettes produced in a single country, the associated production processes generate considerable quantities of oil mist. Implementing advanced purification solutions can help factories maintain compliance with environmental regulations while also boosting productivity. By harnessing these technologies, manufacturers can unlock competitive advantages, reduce maintenance costs, and ultimately contribute to a more sustainable industrial ecosystem. The integration of oil mist purifiers thus represents a strategic investment for factories looking to thrive in a rapidly evolving market.