- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In today’s globalized economy, the demand for high-quality metalworking parts has surged, driven by advancements in technology and increasing production requirements across various sectors. According to a report from IBISWorld, the metalworking industry in China is projected to reach a market size of over $300 billion by 2025, reflecting the country’s pivotal role as a leading manufacturer of metal components. With competitive labor costs and a robust supply chain, China has positioned itself as the go-to destination for businesses seeking reliability and excellence in the metalworking of parts. This ultimate guide will delve into the intricacies of partnering with Chinese manufacturers, highlighting the benefits, processes, and strategies for optimizing your metalworking needs, ensuring that you can navigate this dynamic landscape with confidence.

China has established itself as a dominant force in the global manufacturing landscape, particularly in the realm of metalworking parts. With a staggering production output amounting to over $3 trillion in 2022, China's industrial sector continues to flourish, driven by rapid technological advancements and a skilled workforce. This impressive figure reflects the country's commitment to enhancing efficiency and innovation in manufacturing processes, making it an ideal partner for businesses seeking high-quality metalworking solutions.

Five key attributes contribute to China's leadership in manufacturing premium metalworking parts. Firstly, cost-effectiveness is a significant factor; according to a report by McKinsey, labor costs in China remain competitive compared to Western countries, allowing firms to benefit from reduced production expenses. Secondly, the extensive supply chain ecosystem in China facilitates seamless material acquisition and logistics, ensuring timely deliveries. Thirdly, China's emphasis on research and development, as illustrated by its allocation of approximately 2.4% of GDP to R&D investment, cultivates continuous improvement and innovation. Moreover, stringent quality control measures ensure that products meet international standards, while the scalability of operations allows manufacturers to quickly adapt to fluctuating market demands. These attributes collectively make China an indispensable partner in the metalworking industry.

China has established itself as a global leader in metalworking, significantly impacting various industries with its advanced manufacturing capabilities. One of the top sectors benefiting is the automotive industry, where the demand for precision-engineered parts is crucial. According to a report by McKinsey, the automotive market in China is projected to reach 35 million units by 2025, driving the need for high-quality metal components that can withstand rigorous production standards. This need has catalyzed partnerships with local manufacturers skilled in crafting intricate metal parts essential for vehicle assembly.

The aerospace industry is another major beneficiary of China's metalworking expertise. With the global aerospace market expected to surpass $834 billion by 2028, Chinese manufacturers play a pivotal role in supplying lightweight and durable metal parts that meet stringent regulatory standards. As per the Aerospace Industries Association, the demand for advanced materials and components is rising, making China's capabilities in aerospace parts manufacturing a valuable asset for international companies looking to optimize their supply chains.

Lastly, the electronics sector thrives on China's metalworking prowess, particularly in producing enclosures and connectors that require high precision. A report from Statista indicates that the global electronics production value is set to reach $2.5 trillion by 2025, with substantial contributions from Chinese manufacturers. Their expertise ensures not just volume but also innovation in the design and functionality of electronic components, fostering growth in this rapidly evolving industry.

| Industry | Metalworking Applications | Key Benefits | Estimated Market Size (USD Million) |

|---|---|---|---|

| Automotive | Precision components, chassis parts | High precision, cost-effective production | 2,000 |

| Aerospace | Structural components, turbine parts | Lightweight materials, stringent quality control | 1,500 |

| Electronics | Casings, connectors, circuit board mounts | High-volume production, rapid prototyping | 1,200 |

| Construction | Structural beams, fasteners | Durability, custom solutions | 800 |

Quality control is a cornerstone of excellence in metalworking manufacturing. As the global market for high-purity quartz sand is set to grow significantly, reaching an estimated 944.7 million by 2033, the precision of metalworking parts becomes increasingly vital. Consistent quality control ensures that every component meets stringent industry standards, leading to enhanced product reliability. This is particularly essential in today’s connected and competitive landscape, where even minor defects can lead to substantial operational disruptions.

Quality control is a cornerstone of excellence in metalworking manufacturing. As the global market for high-purity quartz sand is set to grow significantly, reaching an estimated 944.7 million by 2033, the precision of metalworking parts becomes increasingly vital. Consistent quality control ensures that every component meets stringent industry standards, leading to enhanced product reliability. This is particularly essential in today’s connected and competitive landscape, where even minor defects can lead to substantial operational disruptions.

Moreover, the rise of smart manufacturing equipment signifies a pivotal shift in production efficiency. Advanced technologies enable manufacturers to implement rigorous quality control measures throughout the production process, ensuring that each phase adheres to predefined specifications. This not only boosts confidence among clients but also strengthens the overall integrity of the supply chain. As the smart equipment industry surpasses 3.2 trillion, integrating quality assurance within these systems is no longer optional but a necessary strategy for any manufacturer aiming to thrive in the global marketplace.

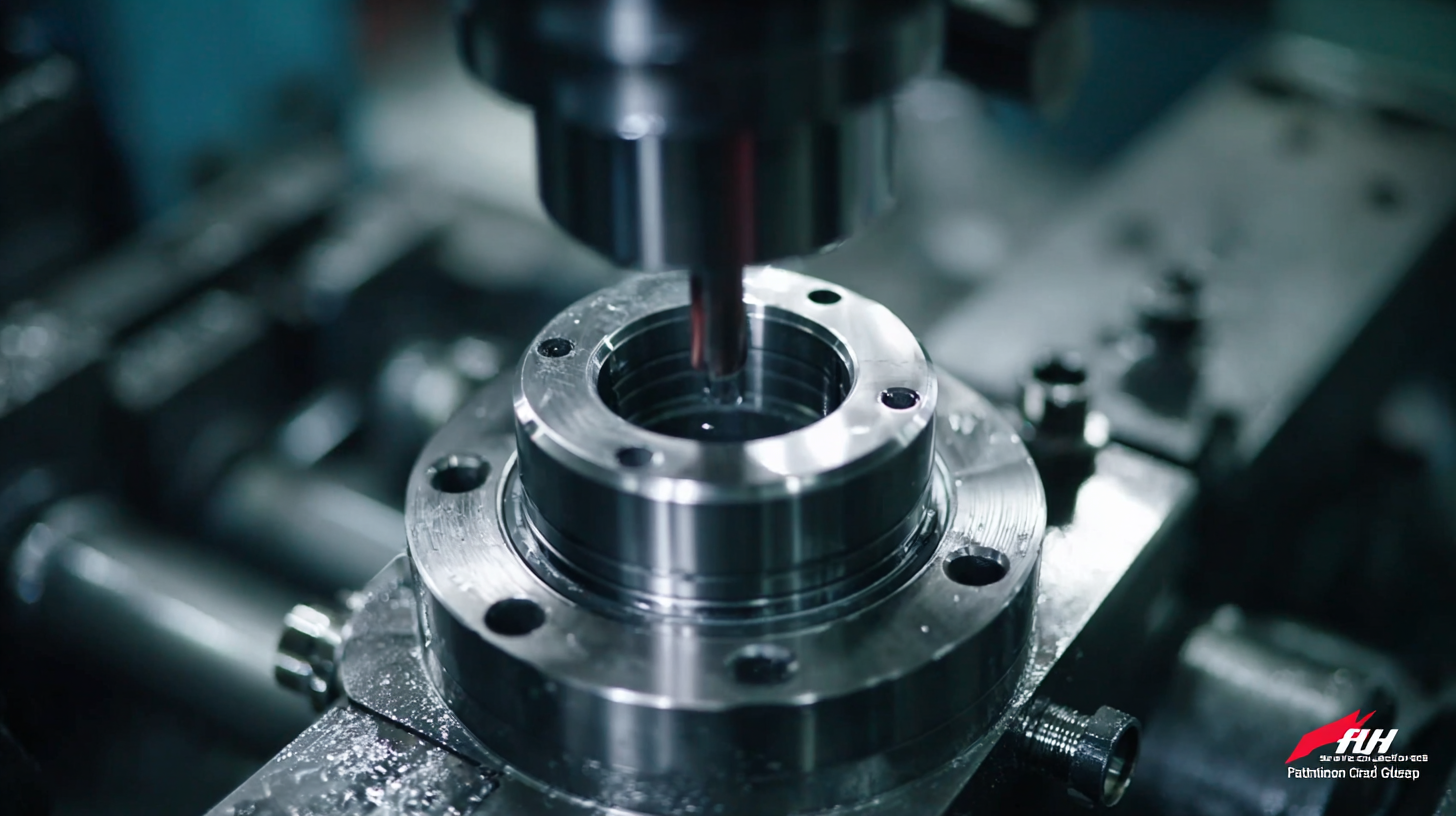

China's metalworking industry has undergone a remarkable transformation driven by advanced technology, making it a trusted global manufacturing partner. The integration of automation in metal fabrication processes has significantly increased efficiency and precision. Automated systems reduce human error, optimize production speed, and ensure consistent quality, allowing businesses to meet rigorous global standards. This technological leap has empowered manufacturers to produce complex parts that cater to diverse industry needs.

Another pivotal factor is the adoption of cutting-edge materials and techniques in metalworking. Innovations such as computer-aided design (CAD) and 3D printing have revolutionized the way components are conceived and manufactured. These technologies enable rapid prototyping and the ability to visualize designs before physical production, accelerating the overall development cycle. Additionally, advanced machining equipment, equipped with AI-driven controls, allows for greater flexibility and customization in producing parts, ensuring that customer specifications are met with unparalleled accuracy.

When selecting the right manufacturing partner in China for your metalworking needs, it's crucial to consider a few key factors that can significantly impact your project's success. First, assess the partner's experience and specialization in metalworking. A manufacturer with a strong track record in producing specific metal parts will likely possess the expertise needed to deliver high-quality results that meet industry standards.

Another important aspect to evaluate is the manufacturer's quality control mechanisms. Ensure they have rigorous inspection processes in place to maintain high production standards. This commitment to quality not only minimizes defects but also contributes to the efficiency of your supply chain. Furthermore, strong communication is essential; you should look for a partner who is responsive and willing to collaborate closely with your team throughout the production process.

Lastly, consider the scaling capabilities of the manufacturer. If your business plans to grow, you need a partner who can adapt to increased demand without compromising on quality. By focusing on these essential tips—experience, quality control, communication, and scalability—you'll be better positioned to select a trusted manufacturing partner in China that aligns with your metalworking requirements.