- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In today's competitive industrial landscape, optimizing custom metalworking processes has become essential for manufacturers aiming to enhance efficiency and product quality. According to a recent report by the National Association of Manufacturers, the metalworking industry contributes over $1 trillion to the U.S. economy annually, highlighting its significant role. The push for increased efficiency in custom metalworking involves adopting advanced technologies and lean manufacturing principles, which can bolster productivity and reduce waste. Industry experts indicate that businesses that invest in process optimization can see productivity improvements of up to 30%, ultimately leading to higher profit margins and customer satisfaction. As manufacturers strive to meet rising demands for customized components and rapid turnaround times, understanding how to streamline these processes effectively has never been more critical.

In custom metalworking operations, identifying key areas for improvement is essential for enhancing both efficiency and quality. One of the foremost areas to evaluate is the workflow. Streamlining the steps involved in production—from raw material procurement to final inspection—can significantly reduce bottlenecks. Implementing lean manufacturing principles, such as value stream mapping, can help pinpoint wasteful practices, enabling teams to focus on optimizing processes that directly contribute to quality output.

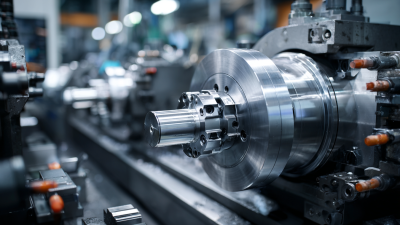

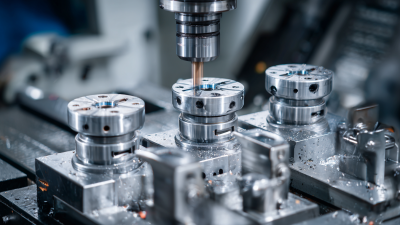

Another critical area to assess is the utilization of technology and machinery. Investing in advanced tools, such as CNC machines and automated systems, can lead to increased precision and reduced human error. Regular maintenance and upgrades of existing equipment also ensure that operations run smoothly, minimizing downtime. Furthermore, fostering a culture of continuous improvement among the workforce encourages the sharing of best practices and innovative ideas, which collectively contribute to enhanced quality in custom metalworking. By focusing on these key areas, companies can achieve a robust operational framework that enhances both efficiency and product excellence.

Implementing advanced technologies in custom metalworking processes is crucial for enhancing efficiency and quality. According to a recent report by MarketsandMarkets, the global metal fabrication market is projected to reach $22.74 billion by 2025, driven by the increased adoption of automation and smart technologies. These innovations not only reduce labor costs by up to 30% but also significantly improve precision in metalworking processes. By integrating technologies such as CNC machining and robotic welding, manufacturers can achieve tighter tolerances and significantly lower error rates.

Moreover, leveraging data analytics and IoT in metalworking provides real-time insights into production processes. A study from Deloitte indicates that companies employing can reduce production cycles by as much as 25%. The ability to monitor machinery performance and material usage in real time allows firms to implement predictive maintenance strategies, further minimizing downtime. As a result, manufacturers not only enhance their operational efficiency but also elevate the quality of their finished products, setting a new standard in the competitive metalworking industry.

When it comes to achieving optimal metalworking results, exploring alternative materials can significantly enhance both efficiency and quality in production processes. Traditional metals such as steel and aluminum have been industry standards, but innovations in materials science introduce a wealth of options that can lead to superior performance characteristics. For instance, composites and high-strength alloys can deliver better weight-to-strength ratios, enabling manufacturers to create lighter yet more durable products. Utilizing these modern materials can also reduce waste, as they often require less machining and provide greater design flexibility.

When it comes to achieving optimal metalworking results, exploring alternative materials can significantly enhance both efficiency and quality in production processes. Traditional metals such as steel and aluminum have been industry standards, but innovations in materials science introduce a wealth of options that can lead to superior performance characteristics. For instance, composites and high-strength alloys can deliver better weight-to-strength ratios, enabling manufacturers to create lighter yet more durable products. Utilizing these modern materials can also reduce waste, as they often require less machining and provide greater design flexibility.

Furthermore, incorporating materials like titanium or advanced polymers can bring unique advantages to specific applications. Titanium is renowned for its corrosion resistance and strength, making it an excellent choice in aerospace and medical industries. Meanwhile, advanced polymers can offer thermal and electrical insulation, providing solutions in environments where traditional metals may falter. By embracing these alternative materials, metalworking professionals can not only optimize their processes for higher efficiency but also enhance the overall quality of their final products, ultimately leading to greater customer satisfaction and competitive advantage in the market.

Streamlining workflow in metal fabrication is essential for achieving both efficiency and high-quality output. One of the most effective practices is to implement a lean manufacturing approach. This involves identifying and eliminating waste in every segment of the production process, from material handling to finishing operations. By analyzing each step and focusing on continuous improvement, businesses can significantly enhance their productivity while reducing costs. Tools such as value stream mapping can help visualize the flow of materials and identify bottlenecks, enabling teams to make data-driven decisions.

Another key strategy is the integration of modern technology into the fabrication process. Employing automation and advanced machinery can drastically improve precision and consistency. For instance, CNC machines and robotic arms can take over repetitive tasks, allowing skilled workers to focus on more complex operations. Additionally, using software for project management can streamline communication and scheduling, reducing downtime between processes. By investing in both technology and employee training, fabricators can ensure that their teams are equipped to operate efficiently while maintaining the highest quality standards.

Quality control is a critical component of any custom metalworking process, as it ensures that the output meets both industry standards and customer expectations. Implementing a robust quality control system begins with establishing clear specifications for each project. This involves defining precise dimensions, tolerances, and material properties, which should be communicated effectively to all team members involved in the production process. By setting these benchmarks, every stage of manufacturing can be monitored closely to ensure compliance, effectively reducing the likelihood of defects and rework.

In addition, routine inspections and testing play an essential role in maintaining product consistency. Employing various methods, such as non-destructive testing or visual inspections at key stages of production, helps identify potential issues before they escalate. Training staff to recognize common defects and apply corrective measures immediately fosters a culture of quality within the organization. Leveraging technology, such as real-time monitoring systems, can further enhance quality control by providing instant feedback and data analytics to guide decision-making. These strategies not only improve the overall quality of metalwork output but also contribute to greater efficiency and customer satisfaction.

| Process Step | Efficiency Measure | Quality Control Measure | Expected Outcome |

|---|---|---|---|

| Cutting | Optimize cutting speed and feed rate | Regular tool wear inspections | Reduced cycle time |

| Welding | Automate welding processes | Use welding procedure specifications (WPS) | Consistent joint quality |

| Finishing | Implement surface treatment technologies | Perform final inspection with calibrated tools | Improved surface quality |

| Assembly | Streamline assembly line layout | Quality audits during assembly | Reduced assembly defects |

| Packaging | Automate packaging processes | Conduct package integrity testing | Enhanced product protection |