- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

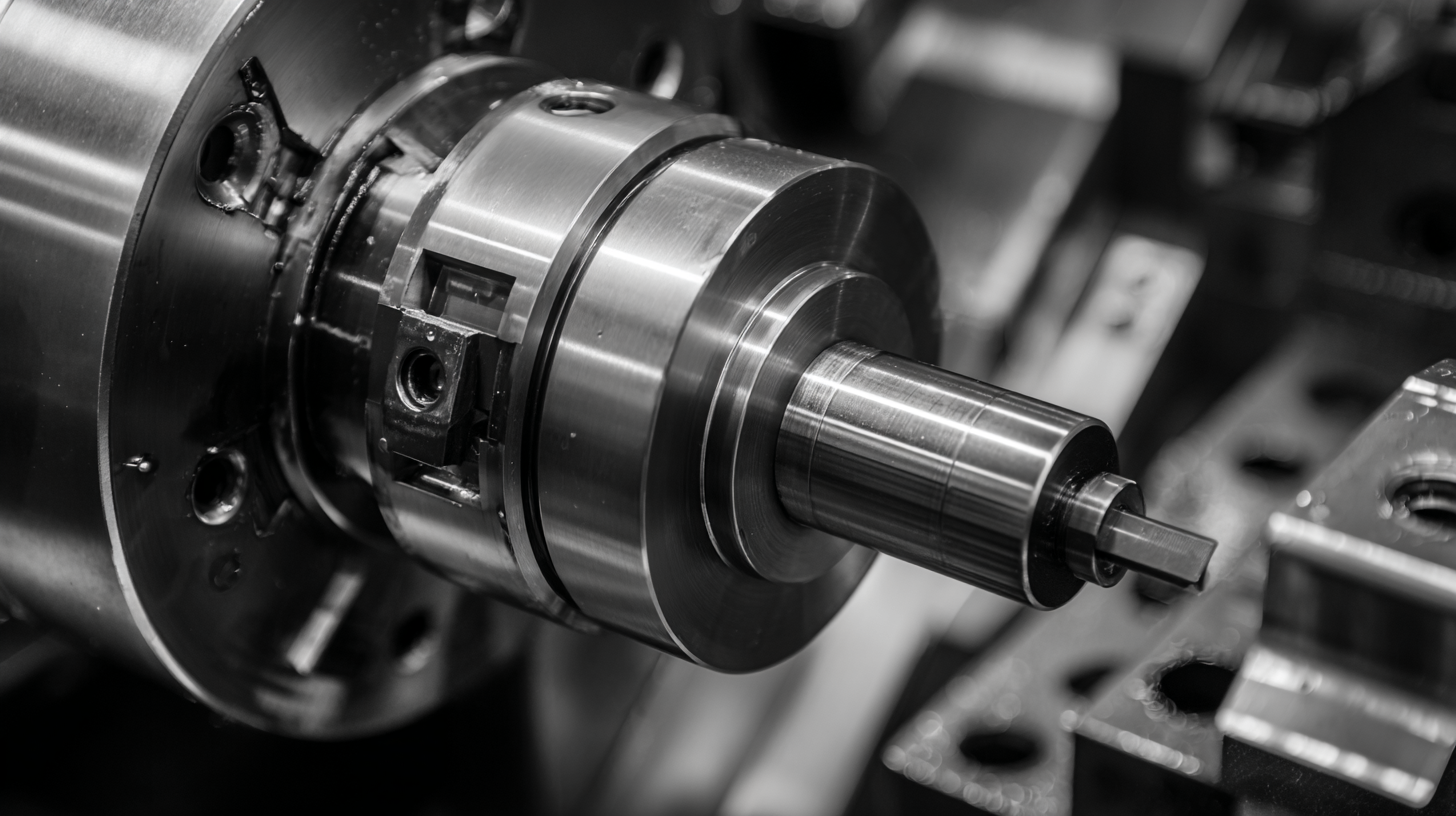

In the rapidly evolving landscape of modern machining processes, the precision and efficiency of manufacturing operations have become paramount. Collets for lathe play an essential role in this context by ensuring that workpieces are securely held and precisely machined. According to a report by the International Federation of Robotics, the global market for industrial robots is projected to reach $110 billion by 2025, highlighting the growing reliance on advanced machinery and tooling systems. Furthermore, a survey by the National Association of Manufacturers indicates that 90% of manufacturers consider precision tooling instrumental in reducing waste and production costs.

As manufacturers strive to enhance operational efficiency and product quality, understanding the dynamics of collets for lathe becomes crucial. These versatile tools not only improve accuracy but also adapt to a variety of workpiece sizes and shapes, underscoring their indispensable role in contemporary machining applications.

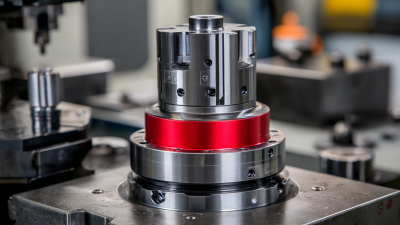

Collets are an essential component in modern machining processes, providing precise clamping for various workpieces. There are several types of collets, each designed for specific applications, which underscores the importance of understanding their unique characteristics for optimizing machining efficiency. For instance, ER collets are renowned for their versatility and hold tolerances of ±0.0005 inches, making them ideal for high-precision turning and milling operations. On the other hand, 5C collets are favored for their clamping range and ease of use, frequently chosen for manual and CNC lathes.

When selecting a collet type, consider the material and geometry of your workpieces. For example, hardened steel or aluminum requires different clamping solutions. Utilizing the right collet can enhance tool longevity and ensure tighter tolerances in components, ultimately leading to a reduction in production costs.

Tips: Always check the manufacturer's specifications for your collet to ensure compatibility with your lathe. Regularly inspect collets for wear or damage, as even minor imperfections can lead to significant inaccuracies in machining. Additionally, utilizing collet blocks can help streamline setups and quickly interchange different collets for improved efficiency.

The performance of collets in lathe operations is greatly influenced by the material from which they are made. Selecting the appropriate material can significantly enhance the collet's ability to grip workpieces securely, thus ensuring accurate machining processes. Common materials used for collet manufacturing include steel, aluminum, and specialized alloys, each offering distinct advantages and disadvantages depending on the application. Steel collets, for example, provide excellent durability and resistance to wear, making them ideal for heavy-duty machining tasks. Conversely, aluminum collets are much lighter, reducing the overall inertia during high-speed operations, which can improve precision.

In addition to strength and weight considerations, the choice of material also affects thermal stability and flexibility during machining. Certain materials can withstand higher temperatures without deforming, ensuring that the collet maintains its form under the pressures of intensive machining operations. Moreover, the right material selection can minimize chatter and vibrations, which are detrimental to precision. By focusing on material characteristics, manufacturers can produce collets that not only meet the specific demands of modern machining processes but also contribute to an overall increase in productivity and accuracy.

| Material Type | Tensile Strength (MPa) | Hardness (HB) | Temperature Resistance (°C) | Typical Applications |

|---|---|---|---|---|

| Steel Alloy | 600 | 200 | 200 | Precision machining, automotive parts |

| Aluminum Alloy | 310 | 110 | 150 | Lightweight components, aerospace |

| Brass | 260 | 80 | 120 | Plumbing fittings, electrical components |

| Carbon Fiber Reinforced Polymer | 700 | 80 | 80 | High-strength applications, aerospace |

| Ceramic | 350 | 150 | 1000 | High-temperature applications, aerospace |

In today's precision machining landscape, collets play a pivotal role in enhancing tool stability. According to a report by the American Society of Mechanical Engineers (ASME), achieving precision in machining processes is increasingly reliant on effective toolholding mechanisms. Collets, known for their superior gripping capability, can reduce runout to as low as 0.0005 inches, significantly improving overall accuracy. This precision is crucial as manufacturers strive to meet tighter tolerances, with many sectors requiring ±0.001 inches or better.

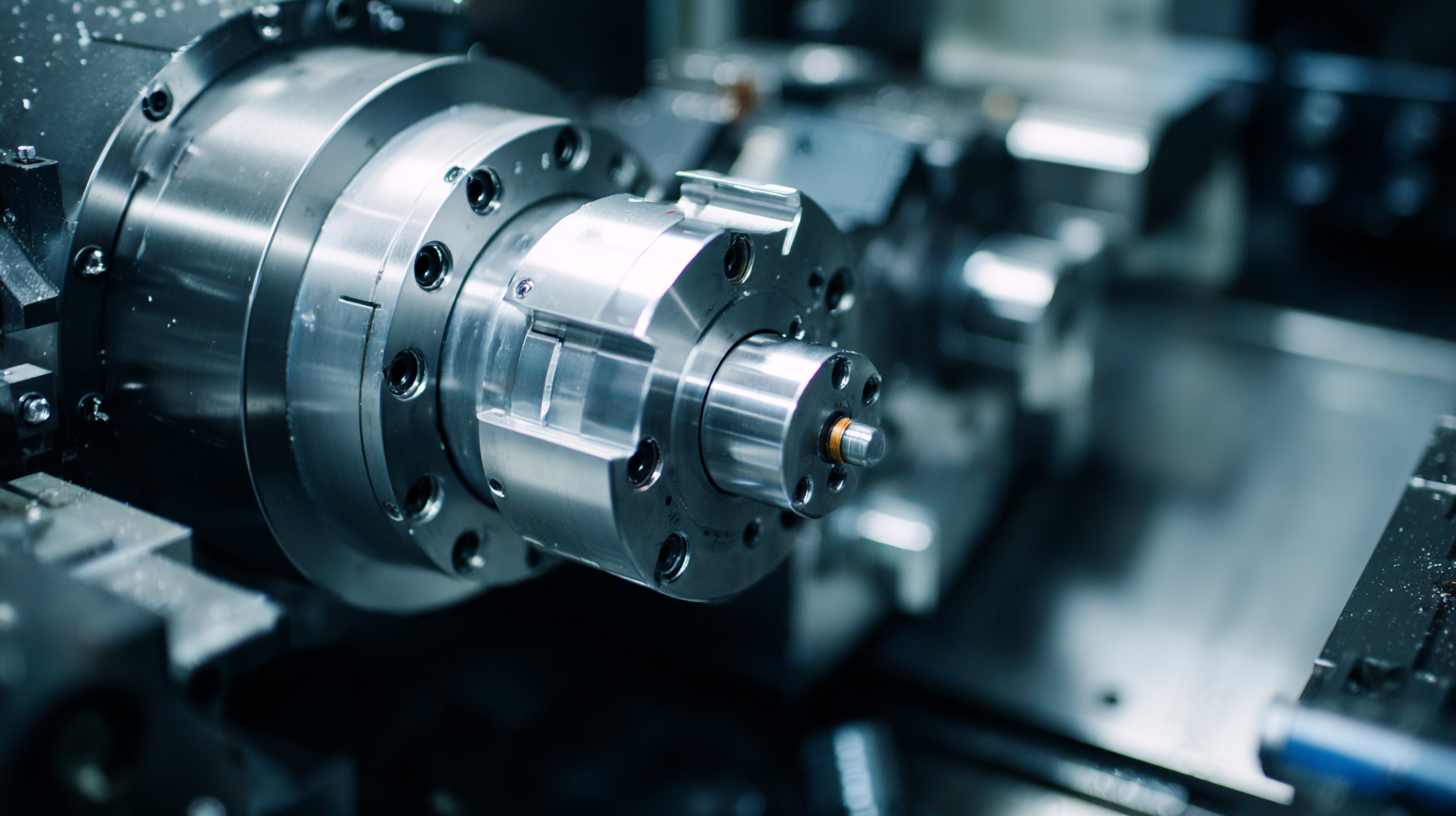

Collets play a crucial role in various lathe operations, acting as precision holding devices to secure workpieces and tools. One primary application of collets is in shaft gripping, where their ability to uniformly distribute clamping force allows for the accurate machining of cylindrical parts. This is particularly important in high-speed machining, where stability and precision are paramount. The use of collets in these scenarios minimizes runout and vibration, leading to superior surface finishes and tighter tolerances.

Another significant application is in tool holding, where collets accommodate different tool types and sizes with ease. In lathe operations such as turning, drilling, and milling, quick tool changes facilitated by collets enhance productivity and efficiency. Moreover, the ability of collets to handle various materials, from metal to plastic, makes them versatile for numerous industrial applications. This flexibility enables machinists to adapt quickly to different production requirements without compromising on precision or quality.

In modern machining processes, the precision of operations heavily relies on the effective use of collets. These devices play a critical role in toolholding, ensuring stability and accuracy during machining. However, their performance can significantly deteriorate due to improper maintenance, leading to inaccuracies in machining. According to industry reports, even slight deviations in tool alignment can cause up to 25% loss of precision, emphasizing the necessity of regular collet maintenance.

One of the common mistakes shops face is neglecting the wear and tear of ER collets. As tools are subject to repeated stress, friction, and heat, collets can develop damage that compromises their effectiveness. To prevent this, it’s essential to regularly inspect collets for signs of wear and to replace them as needed. Proper cleaning and lubrication can greatly extend the lifespan of collets and maintain their precision.

**Tips for Maintaining Collets:**

1. Regularly check and clean collets after use to remove debris and prevent buildup.

2. Store collets in a protective case or tray to avoid physical damage.

3. Rotate collets among different tools to ensure even wear over time.

By focusing on the maintenance of collets, shops can significantly improve their machining accuracy and efficiency. The investment in proper care pays off through enhanced tool performance and reduced operational costs.