- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the realm of precision machining, selecting the right tools is paramount, particularly when working with aluminum, which is renowned for its lightweight and machinability. The efficiency and accuracy of CNC machining greatly depend on the appropriate choice of CNC bits for aluminum, as improper tool selection can lead to diminished performance and increased costs.

According to a report by the International Data Corporation, the global CNC machine market is expected to reach $100 billion by 2025, driven by advancements in technology and a surge in manufacturing demand.

Furthermore, effective machining techniques using specialized CNC bits can enhance production efficiency by 40% and significantly reduce material waste. This comprehensive guide aims to empower machinists and manufacturers with the knowledge needed to master CNC bits for aluminum, ensuring optimal performance and results in precision machining endeavors.

When it comes to CNC machining, understanding the properties of aluminum is essential for achieving optimal outcomes. Aluminum, with its unique combination of lightweight and high strength, is widely used in various industries. According to recent studies, the machinability of aluminum can significantly enhance when employing the right cutting tools and techniques. For instance, innovations in cutting tools have demonstrated improvements in efficiency and precision, allowing for enhanced performance when tackling complex geometries inherent in aluminum components. Effective tooling selection can lead to a decrease in tool wear while maximizing production rates, with reports indicating that proper tooling can improve machining rates by up to 30%.

Furthermore, the advent of hybrid manufacturing techniques, including generative design, is reshaping the way aluminum parts are conceptualized and produced. Utilizing software tools like Fusion 360, designers can create optimized parts that are not only suitable for subtractive machining but also adaptable for additive methods. This approach leverages the strengths of both manufacturing processes, thereby extending the capabilities of aluminum machining. Recent analytical models also highlight the machinability of advanced aluminum composites, revealing that incorporating materials such as vanadium carbide can further enhance the performance of aluminum alloys, making them more competitive in high-load applications. The integration of data-driven methodologies is proving to be fundamental in unlocking the full potential of aluminum in CNC machining.

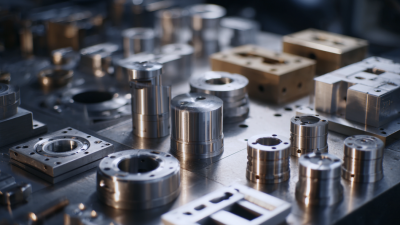

When it comes to machining aluminum, selecting the right CNC bits is crucial for achieving precision and efficiency. Essential CNC bit types for aluminum include end mills, ball nose mills, and insert mills, each boasting unique functions and characteristics tailored for aluminum’s properties. According to a recent industry report by the U.S. Department of Commerce, the aerospace and automotive sectors alone are expected to drive a 6% annual growth in the demand for aluminum components, making the choice of CNC tools in these applications increasingly significant.

End mills, particularly those with a high helix angle, are designed to minimize tool wear and enhance chip removal, thus ensuring smoother finishes. A study by the International Journal of Advanced Manufacturing Technology indicates that using specialized coatings like TiAlN can increase tool lifespan by up to 40% when machining aluminum compared to uncoated tools. On the other hand, ball nose mills are ideal for contouring and finishing work, as their rounded edges allow for better surface quality on 3D shapes. Selecting the right bit for each specific application not only improves the machining process but can also lead to significant cost savings, emphasizing the importance of understanding the functions of different CNC bit types tailored for aluminum.

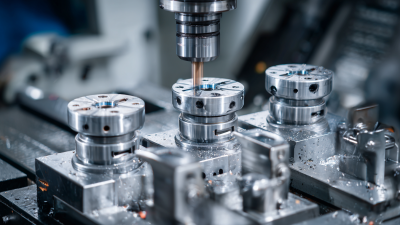

When machining aluminum, understanding the cutting speed and feed rate is crucial for achieving precision. A study conducted by the American Machining Institute highlights that optimal cutting speeds for aluminum typically range between 600 to 1,200 surface feet per minute (SFM). This variation depends on the type of CNC bit used and the specific alloy of aluminum being machined. For instance, a high-speed steel (HSS) bit may require slower cutting speeds compared to carbide tools, which can comfortably handle higher speeds due to their wear resistance and durability.

The feed rate, defined as the distance the tool moves through the material per revolution, also plays a significant role in the machining process. Industry standards suggest that feed rates for aluminum should be approximately 0.001 to 0.004 inches per tooth, depending on the specific application and tooling employed. Inadequate feed rates can lead to poor surface finishes and increased tool wear, while excessive rates may cause chip packing and overheating. By carefully evaluating both cutting speed and feed rate, machinists can optimize their CNC operations, ultimately enhancing productivity while ensuring the integrity of the machined aluminum components.

When it comes to CNC machining of aluminum, the right coating for your bits can significantly enhance tool life and performance. According to a recent industry report by Freedonia Group, tools equipped with advanced coatings can last up to three times longer than uncoated varieties, making them a worthwhile investment for precision machining operations. Coatings such as TiAlN (Titanium Aluminum Nitride) and TiN (Titanium Nitride) not only improve wear resistance but also enhance heat dissipation. This is crucial when machining aluminum at high speeds, where overheating can lead to tool failure and diminished workpiece quality.

Tips: Always consider the specific type of aluminum you are machining. For softer alloys, a TiN coating is generally sufficient, while harder alloys may benefit from the improved durability of TiAlN. Additionally, factor in the coolant used during machining, as some coatings handle lubrication differently and can affect performance.

Choosing the right coating also involves understanding your machining conditions. A study by the Machining Research Institute found that bits with a suitable coating can improve cutting speeds by up to 20%, thereby optimizing production efficiency. Evaluating these factors carefully can lead to not only better tool longevity but also higher precision in your machining projects, ultimately resulting in superior end products.

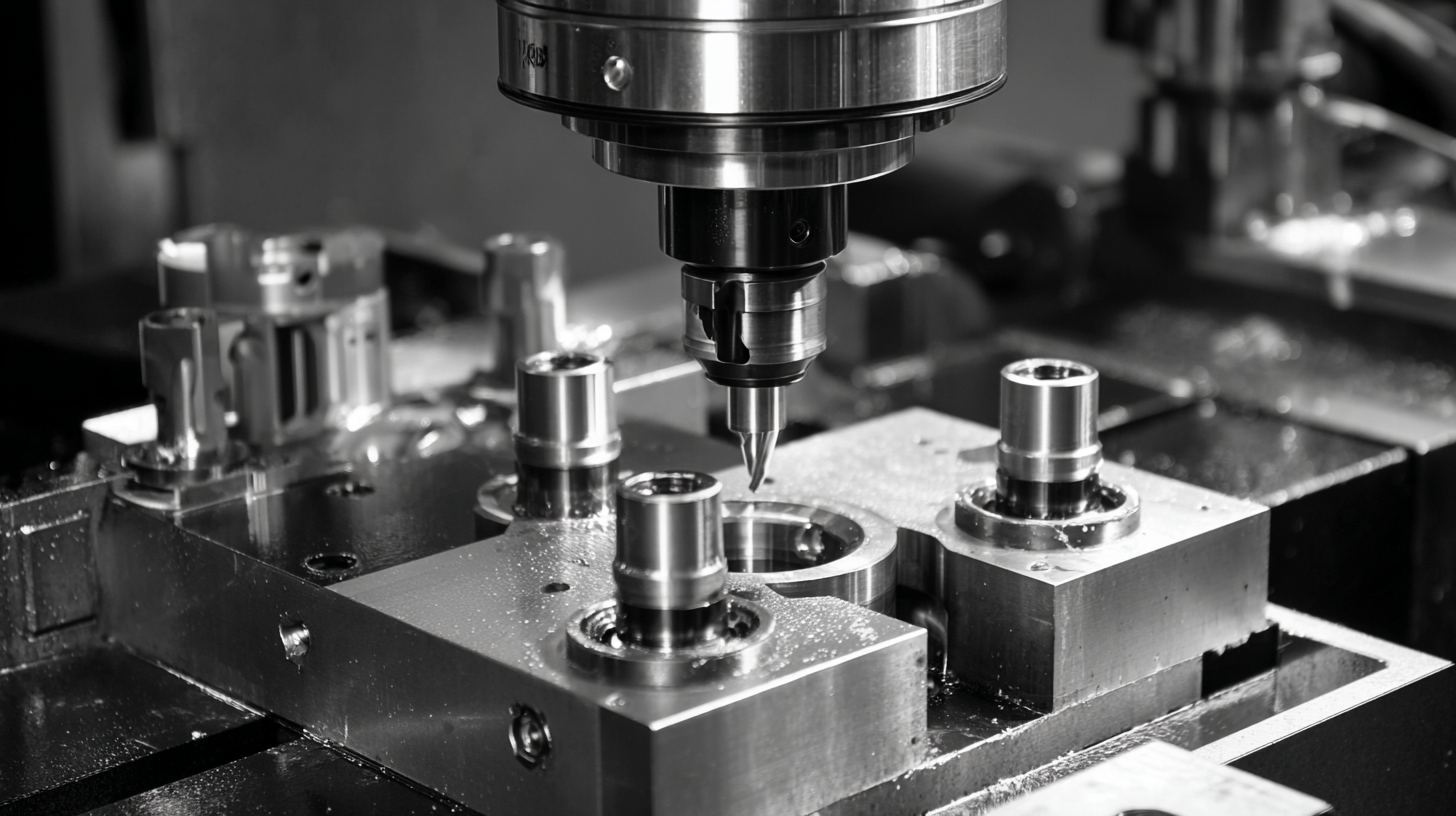

When machining aluminum, proper tool maintenance and setup are crucial for achieving precision and prolonging the lifespan of your CNC bits. One key practice is to ensure that your tools are clean and free of debris before starting a job. Regularly inspecting and cleaning the bits helps maintain sharpness and prevents buildup that can lead to overheating and tool wear. Additionally, always check for any signs of damage, such as nicks or dull edges, and replace bits as necessary to ensure optimal performance.

Setting up your CNC machine correctly is equally important. Start by selecting the appropriate feed rate and speed for aluminum, as these factors directly impact the quality of the finished part. Establishing a balanced coolant system is essential to manage heat buildup and keep the tooling efficient. Experimenting with different toolpath strategies, such as climb milling or conventional milling, can further enhance machining outcomes. By focusing on these best practices for tool maintenance and setup, machinists can achieve high precision while minimizing operational downtime and maximizing tool life.

| Bit Type | Diameter | Material | Recommended RPM | Feed Rate (IPM) | Tool Life (Hours) |

|---|---|---|---|---|---|

| Ball Nose | 1/4" | Carbide | 8000 | 25 | 120 |

| Flat End Mill | 1/2" | HSS | 6000 | 20 | 80 |

| Chamfer Tool | 3/8" | Carbide | 7000 | 15 | 100 |

| Tapered End Mill | 1/8" | Carbide | 9000 | 18 | 90 |