- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

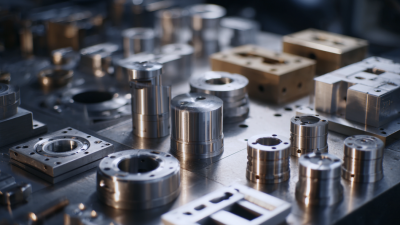

In today's rapidly evolving industrial landscape, the "Processing of Parts" has become a critical focal point for enhancing operational efficiency and product quality across various sectors. As industries strive to meet increasing demands for precision and reliability, innovative approaches in parts processing are proving essential. This blog explores cutting-edge solutions that not only streamline production workflows but also improve the overall performance of parts. By leveraging advanced technologies, such as automation, additive manufacturing, and data analytics, manufacturers are redefining their practices to achieve superior results. Join us as we delve into the latest trends and techniques that are revolutionizing the processing of parts, ultimately leading to enhanced competitiveness and sustainable growth in the industry.

In today's rapidly evolving industrial landscape, the "Processing of Parts" has become a critical focal point for enhancing operational efficiency and product quality across various sectors. As industries strive to meet increasing demands for precision and reliability, innovative approaches in parts processing are proving essential. This blog explores cutting-edge solutions that not only streamline production workflows but also improve the overall performance of parts. By leveraging advanced technologies, such as automation, additive manufacturing, and data analytics, manufacturers are redefining their practices to achieve superior results. Join us as we delve into the latest trends and techniques that are revolutionizing the processing of parts, ultimately leading to enhanced competitiveness and sustainable growth in the industry.

In today's fast-paced industrial landscape, innovative technologies are revolutionizing part processing, enhancing both efficiency and quality. Advanced automation tools, such as robotic arms and machine learning algorithms, are redefining traditional manufacturing processes. These technologies allow for precise machining and rapid production cycles, minimizing waste and maximizing output. Industries like aerospace, automotive, and medical manufacturing are leveraging these advancements to streamline operations and improve product quality.

Tip: Integrating IoT (Internet of Things) sensors into your manufacturing setup can provide real-time data on machine performance and product quality, facilitating immediate adjustments and reducing downtime.

Furthermore, additive manufacturing, or 3D printing, is gaining momentum as a game-changer in part processing. This technology enables the creation of complex geometries that traditional methods cannot achieve, allowing for lightweight structures and customized parts at a fraction of the cost. As companies embrace this cutting-edge approach, they benefit from reduced lead times and enhanced design flexibility.

Tip: Consider adopting an agile manufacturing strategy that incorporates modular design principles. This allows for quicker adjustments to production techniques in response to changing market demands.

In today's rapidly evolving manufacturing landscape, streamlining workflows has become paramount for enhancing efficiency and product quality. By adopting best practices such as lean manufacturing principles, organizations can minimize waste and optimize resource allocation. This proactive approach ensures that each stage of production is streamlined, reducing bottlenecks and improving overall throughput. Implementing technology-driven solutions, such as real-time data analytics, allows manufacturers to monitor performance metrics closely and make informed decisions to fine-tune processes.

Additionally, fostering a culture of continuous improvement is essential. Engaging employees at all levels in problem-solving initiatives helps uncover inefficiencies that may not be visible from the top. Regular training and open communication about workflow practices can empower teams to suggest innovative modifications, ultimately leading to a more agile manufacturing environment. By integrating these best practices into their operations, companies can not only boost efficiency but also enhance product quality, driving long-term success in a competitive market.

In today's competitive manufacturing landscape, ensuring high standards in part production is crucial for sustaining operational excellence. Quality control innovations play a pivotal role in achieving this goal. According to a recent report by the International Journal of Advanced Manufacturing Technology, companies utilizing advanced quality control systems have seen a 20% reduction in defect rates, significantly enhancing product reliability and customer satisfaction.

One of the most impactful innovations is the implementation of real-time monitoring technologies, such as machine learning algorithms and IoT sensors. These tools allow manufacturers to detect anomalies in the production process as they occur, facilitating immediate corrective actions. Furthermore, adopting 3D printing technologies has enabled firms to produce complex parts with minimal waste, demonstrating an overall improvement in both efficiency and product quality.

Tip: To optimize your quality control processes, consider integrating automated inspection systems that utilize AI-driven analytics to identify defects early in the production cycle.

Another emerging trend is the use of cloud-based quality management systems, which enable seamless data sharing and real-time collaboration among teams. This approach not only enhances transparency but also fosters a culture of continuous improvement. By leveraging these innovative quality control strategies, manufacturers can accelerate their production capabilities while maintaining stringent quality standards.

Tip: Regular training programs for employees on the latest quality management tools can further enhance adherence to high production standards and encourage proactive problem-solving in quality assurance.

In today's manufacturing landscape, the push towards sustainability is reshaping the way parts are processed, making eco-friendliness a priority alongside efficiency. Companies are increasingly adopting innovative materials and techniques that minimize waste and reduce energy consumption. Techniques such as additive manufacturing, which builds parts layer by layer, not only lower material waste but also allow for more complex designs that traditional methods struggle to achieve. This shift not only meets regulatory demands but also caters to a growing consumer base that values environmentally responsible products.

Furthermore, the integration of smart technologies in part processing has opened avenues for real-time monitoring and optimization. By utilizing IoT sensors and AI-driven analytics, manufacturers can fine-tune their processes to enhance efficiency while simultaneously cutting down on resources. For instance, precise control over machining processes can lead to reduced scrap rates, thereby ensuring that operations are as eco-friendly as possible. As industries strive to balance productivity with sustainability, embracing these innovative approaches becomes not just a competitive advantage but a necessary step toward a more responsible future in manufacturing.

In the rapidly evolving landscape of part processing technology, the integration of advanced digital tools is setting the stage for significant industry transformation. With the rise of Artificial Intelligence (AI) in manufacturing, particularly among small and medium-sized enterprises, organizations are striving for optimized resource orchestration to boost productivity and quality. According to recent insights from the McKinsey Technology Council, the adoption of AI and data analytics can lead to substantial efficiency gains across the supply chain, emphasizing the importance of adapting to these innovative paradigms.

As we look toward the future, sustainable development remains a pivotal focus, especially within the framework of Industry 5.0. This new era promises to align technological advancements with environmental sustainability, demanding that companies implement strategic roadmaps to ensure accountability in their processes. Incorporating cutting-edge sustainable building materials can significantly enhance the performance and longevity of products, ultimately contributing to a lower environmental impact.

Tips: One effective strategy for businesses is to leverage automation to streamline operational processes while minimizing resource waste. Regularly updating teams on emerging technological trends can foster a culture of innovation. Finally, investing in training for frontline workers can empower them with the necessary skills to adapt to new technologies, ensuring a more resilient workforce ready to tackle future challenges.