- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

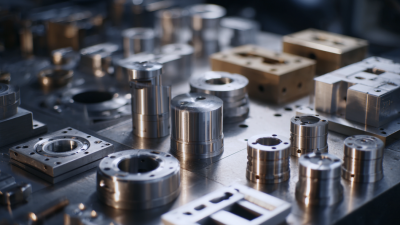

In today's rapidly evolving manufacturing landscape, the demand for Custom Milled Parts has surged, reflecting a 25% growth over the past five years as industries seek precision-engineered components tailored to specific applications. According to a report by MarketsandMarkets, the global CNC machining market is projected to reach $117 billion by 2026, driven by advancements in technology and increasing customization needs across sectors such as aerospace, automotive, and medical device manufacturing. This guide aims to navigate the complexities of custom milling, helping businesses understand their manufacturing options and make informed decisions. As we delve into the nuances of the custom milling process, we will explore the benefits, materials, technologies, and the myriad of applications that underscore the significance of Custom Milled Parts in today’s industrial ecosystem.

Understanding custom milled parts is essential for anyone looking to navigate the manufacturing landscape effectively. At its core, custom milling refers to the process of removing material from a workpiece to achieve precise shapes and dimensions according to specific requirements. This technique allows for a high degree of customization, making it ideal for producing components used in various industries, from aerospace to medical devices. Essential concepts to grasp include the difference between CNC milling and manual milling, the types of materials commonly used, and the significance of tolerances and surface finishes in determining part quality.

Additionally, it's important to appreciate the various manufacturing options available when ordering custom milled parts. These options can range from prototyping small batches to large-scale production runs, each with distinct advantages. Understanding concepts like lead time, cost implications, and the impact of material selection on the overall project outcome will empower you to make informed decisions. As you delve deeper into manufacturing processes, these key definitions and concepts will serve as a foundation for optimizing your design and production strategies.

When it comes to custom milling, material selection plays a pivotal role in determining the quality and cost-effectiveness of the final product. According to a report by Grand View Research, the global CNC machining market is projected to reach $24.09 billion by 2025, emphasizing the increasing demand for precision in manufacturing. The right material not only influences the durability and functionality of the parts but also affects the machining process itself. For instance, aluminum is favored for its lightweight and corrosion resistance, making it ideal for aerospace applications. Meanwhile, stainless steel, with its exceptional strength, is commonly used in industrial machinery.

Tips: When selecting materials, consider the specific application and operating conditions. Conduct a cost-benefit analysis to ensure that the material aligns with both performance requirements and budget constraints.

Furthermore, different materials have varying machinability ratings, impacting cycle times and tooling expenses. For example, high-strength alloys may require specialized tools and longer machining times, ultimately affecting project timelines and costs. Understanding the machinability of materials can help manufacturers optimize their processes and improve production efficiency.

Tips: Always consult with manufacturing experts to assess material properties and your project's unique demands. They can provide insights that lead to effective decisions and resource allocation.

When it comes to manufacturing custom milled parts, understanding the various methods available is crucial. Two prevalent techniques are CNC machining and 3D printing, each offering unique advantages and considerations. CNC machining provides high precision and a superior finish, making it ideal for parts that require tight tolerances and robust material properties. This subtractive manufacturing method carves out shapes from solid blocks of material, ensuring durability and strength. However, the process can be time-consuming and often involves higher material waste.

On the other hand, 3D printing, or additive manufacturing, has gained popularity for its ability to produce complex geometries with minimal material waste. This method allows for rapid prototyping and the creation of intricate designs that would be challenging to achieve through conventional machining. While 3D printing can be less expensive for small production runs and quick iterations, it may not offer the same level of strength or surface finish as CNC machining. Deciding between these methods depends on the project’s requirements, including budget, time constraints, and material specifications, highlighting the importance of a thorough comparative analysis in the selection process.

In the realm of custom milling, precision tolerances play a pivotal role in the manufacturing process. These tolerances dictate how closely a finished part can deviate from the desired specifications. Understanding the standards associated with precision tolerances is critical for engineers and manufacturers alike, as it directly impacts product fit, function, and quality. Whether dealing with intricate parts for aerospace applications or simple components for everyday machinery, maintaining strict control over these tolerances is essential.

When selecting a custom milling service, be sure to discuss the required tolerances at the outset. Manufacturers utilize various tools and techniques to achieve precision, such as CNC milling, which allows for consistent and repeatable results. It's important to note that tighter tolerances often require more sophisticated machinery and experienced operators, which can influence both lead time and cost. Collaborating closely with your chosen manufacturer to define these parameters can significantly streamline the production process and ensure the final parts meet your stringent requirements.

When embarking on a project that involves custom milled parts, understanding the cost implications is crucial. Budgeting for these components requires a comprehensive analysis of various factors that influence pricing. The complexity of the design is often the first element to consider; intricate shapes and specifications can significantly increase machining time and, consequently, costs. Additionally, the choice of material plays a pivotal role. High-grade metals or specialized materials may come with a premium, so balancing quality and cost is essential.

Beyond design and materials, other factors like machining methods, lead times, and order quantities can also sway budget estimates. For instance, opting for advanced manufacturing techniques can enhance precision but may elevate the overall expenditure. Furthermore, if a project anticipates larger volume orders, negotiating bulk pricing with manufacturers could yield substantial savings. Therefore, a meticulous cost analysis not only aids in crafting a realistic budget but also ensures that you are making informed decisions that align with your project's financial constraints and goals.