- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In today's manufacturing landscape, the importance of selecting the right collet manufacturer cannot be overstated. According to a report by Market Research Future, the global collet market is projected to reach USD 1.2 billion by 2027, driven by advancements in precision engineering and the increasing demand for high-quality components across various industries. The right collet can significantly enhance machining efficiency, accuracy, and tool life, making the choice of manufacturer a critical decision for businesses looking to optimize their production processes. With numerous options available, ranging from established leaders to niche players, understanding how to navigate this competitive market is essential for achieving operational excellence and meeting specific machining needs. This guide will provide valuable insights to help you identify the most suitable collet manufacturer for your requirements.

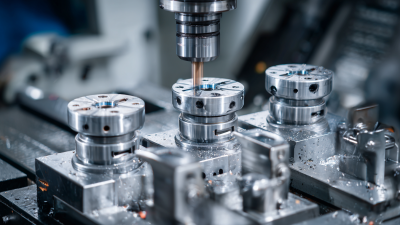

Collets are essential components in various machining processes, acting as a clamp for holding cylindrical workpieces securely in place. Understanding the different types of collets and their specific applications can greatly enhance workflow efficiency and precision in manufacturing. The most commonly used types include spring collets, high-precision collets, and expanding collets, each serving unique purposes. Spring collets are ideal for general-purpose applications where versatility and speed are required, while high-precision collets are designed for applications demanding tighter tolerances and superior accuracy.

In industries such as aerospace, automotive, and electronics, the selection of the right collet can significantly impact the quality of the final product. High-precision collets, for instance, minimize run-out and provide consistent clamping force, making them suitable for tasks involving delicate components or intricate designs. Meanwhile, expanding collets offer an adjustable grip, making them advantageous for handling a variety of workpiece diameters without the need for constant changeovers. By understanding these differences, manufacturers can choose the appropriate collet to optimize their processes and achieve better machining results.

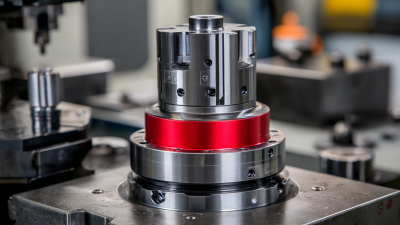

When selecting a collet manufacturer for precision machining, several key factors come into play. First and foremost, consider the manufacturer's experience and expertise in the industry. An established manufacturer with a proven track record can assure you of high-quality products and reliability. Look for testimonials and case studies that demonstrate their ability to meet specific machining requirements. This experience often translates into better technical support and innovations that can enhance your machining processes.

Another crucial aspect to evaluate is the variety and customization of collets offered. Different machining projects may require specific collet designs or sizes, so it's essential to choose a manufacturer that provides a diverse range of options to meet your distinct needs. Additionally, inquire about their willingness to collaborate on custom solutions. A flexible manufacturer can help improve efficiency and precision by tailoring collets that suit your exact specifications. Lastly, don't overlook the importance of materials and manufacturing methods used, as these factors significantly impact the performance and longevity of the collets in demanding applications.

This chart illustrates the importance ratings for key factors to consider when selecting a collet manufacturer for precision machining. Each factor is rated on a scale of 0 to 100, highlighting the significance of material quality and manufacturing precision in the decision-making process.

When evaluating collet manufacturers, understanding their quality standards and certifications is crucial. According to the latest report from the International Organization for Standardization (ISO), over 80% of manufacturers certified under ISO 9001 indicate a significant improvement in product reliability and customer satisfaction. This certification ensures that companies adhere to high-quality management principles, which can significantly impact their manufacturing processes and the durability of the collets produced.

Moreover, customer reviews and testimonials provide valuable insights into a manufacturer's reputation. A study by the Manufacturing Institute found that around 70% of buyers consider online reviews as an essential criterion when selecting suppliers. Engaging with existing customers' feedback can reveal information about the manufacturer’s responsiveness to quality issues, their adherence to deadlines, and the overall performance of their products. Brands that actively encourage customer reviews and ratings often build a more trustworthy image, which can be a deciding factor in choosing the right collet manufacturer for your needs.

When selecting a collet manufacturer, it's essential to consider the balance between cost and quality. A recent industry report from the Machining Association revealed that approximately 30% of manufacturers often prioritize lower costs, which can lead to higher long-term expenses due to quality issues. Investing in high-quality collets not only ensures precision and longevity but can significantly reduce downtime and maintenance costs. By focusing on value rather than just upfront pricing, businesses can achieve better overall efficiency and product quality.

When selecting a collet manufacturer, it's essential to consider the balance between cost and quality. A recent industry report from the Machining Association revealed that approximately 30% of manufacturers often prioritize lower costs, which can lead to higher long-term expenses due to quality issues. Investing in high-quality collets not only ensures precision and longevity but can significantly reduce downtime and maintenance costs. By focusing on value rather than just upfront pricing, businesses can achieve better overall efficiency and product quality.

Tip: Always request samples from potential manufacturers before making a bulk purchase. This allows you to evaluate the quality firsthand and understand how well their products meet your specific operational needs.

Moreover, consider the materials used by various manufacturers. Reports indicate that collets made from superior steel alloys can withstand greater stress and offer better performance. While the initial investment might be higher, the durability and reliability often justify the expense in high-demand environments.

Tip: Engage with manufacturers who offer flexible payment options and warranties. This can help mitigate risks associated with your investment and ensure you are more comfortable with your purchasing decisions.

As the manufacturing industry continues to evolve, collet technology is witnessing significant innovations that promise to enhance precision and efficiency. According to a report by MarketsandMarkets, the global collet market is projected to grow from $1.7 billion in 2020 to $2.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.4%. This growth is driven by advancements in materials and designs that aim to improve clamping capabilities and reduce maintenance costs.

Recent trends indicate that manufacturers are increasingly focusing on automation and digital integration. Technologies such as automated tool changers and smart collets equipped with IoT capabilities allow for real-time monitoring and data collection, ensuring better workflow management and reduced downtime. A study by PwC highlights that 75% of manufacturing executives recognize the value of Industry 4.0 technologies, making it imperative for collet manufacturers to innovate in these areas to stay competitive. As the demand for precision engineering grows, so too will the need for advanced collet solutions that cater to the evolving needs of the industry.

| Feature | Importance (1-5) | Current Trends | Innovations |

|---|---|---|---|

| Material Quality | 5 | Use of durable alloys | Advanced coatings for wear resistance |

| Precision | 5 | Tighter tolerances | Digital inspection methods |

| Customer Support | 4 | 24/7 assistance | AI chatbot integration |

| Customization Options | 4 | Tailored solutions for specific applications | Increased flexibility in production |

| Pricing | 3 | Competitive pricing strategies | Dynamic pricing models |