- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

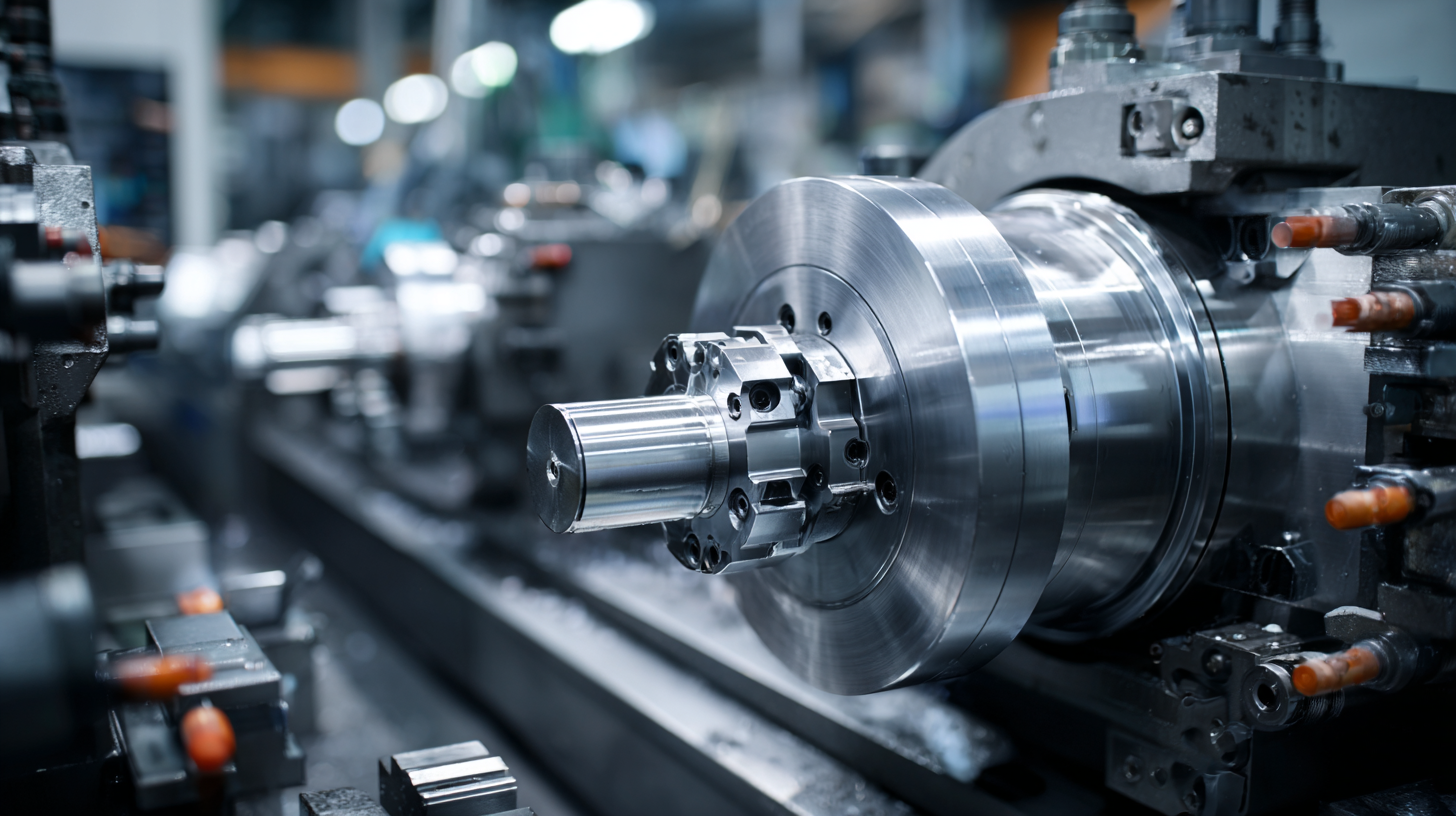

The demand for high-quality Custom Steel Machining solutions has surged significantly in recent years, driven by advancements in technology and increased applications across various industries. According to a report by Grand View Research, the global machining market is expected to reach $260.76 billion by 2025, growing at a CAGR of 6.5%. This growth is largely attributed to the expanding automotive, aerospace, and manufacturing sectors, all of which require precision-engineered steel components. As companies seek competitive advantages through enhanced product quality and manufacturing efficiency, identifying the right manufacturer becomes crucial. In this blog, we will explore the essential criteria for selecting a manufacturer that specializes in Custom Steel Machining, ensuring you receive tailored solutions that meet your specific operational needs while adhering to industry standards and technological innovations.

When it comes to custom steel machining, selecting the right manufacturer is crucial. A report from the National Association of Manufacturers indicates that businesses can experience a productivity increase of up to 30% when they collaborate with manufacturers that understand their specific needs and industry standards. This highlights the importance of not only quality in production but also the alignment of values and capabilities between the manufacturer and the client. A manufacturer with a track record of successful custom steel projects can provide insights and solutions that adapt to fluctuations in market demand, thus ensuring a smoother operational flow.

When it comes to custom steel machining, selecting the right manufacturer is crucial. A report from the National Association of Manufacturers indicates that businesses can experience a productivity increase of up to 30% when they collaborate with manufacturers that understand their specific needs and industry standards. This highlights the importance of not only quality in production but also the alignment of values and capabilities between the manufacturer and the client. A manufacturer with a track record of successful custom steel projects can provide insights and solutions that adapt to fluctuations in market demand, thus ensuring a smoother operational flow.

Tip: Before making a decision, ask potential manufacturers for case studies or references from similar industries. This will give you a sense of their experience and capabilities in handling projects similar to yours.

Moreover, the right manufacturer will be well-versed in technological innovations and compliance standards, which can significantly affect the final product's quality and durability. According to a study by Deloitte, companies that engage with well-equipped suppliers can reduce production errors by nearly 25%. As such, evaluating a manufacturer’s technology and production methods is just as critical as examining their certifications and compliance with industry regulations.

Tip: Don't hesitate to schedule visits to manufacturing facilities. Observing their processes and capabilities first-hand will provide invaluable insights into their operations and overall quality assurance practices.

When selecting a custom steel machining partner, there are several key factors to consider that can significantly influence the quality and efficiency of your projects. A critical component is the manufacturer's technological capabilities. According to a recent report by the Precision Metalforming Association, 72% of manufacturing companies believe that investing in advanced machining technology is crucial for maintaining a competitive edge. Assessing a potential partner's machinery, software, and production techniques can provide insights into their capacity to meet specific project requirements.

Another essential factor is the manufacturer's experience and reputation in the industry. An industry analysis by MarketsandMarkets indicates that the custom machining market is projected to reach USD 3.5 billion by 2025, highlighting the increasing demand for specialized machining solutions. Companies that have a proven track record of successful projects and positive client testimonials are likely to deliver higher quality products. Additionally, evaluating their understanding of industry standards and compliance with regulations ensures that they can handle the complexities associated with custom steel machining, ultimately leading to smoother project execution and enhanced results.

| Key Factors | Description | Importance Level |

|---|---|---|

| Experience | Years of industry experience and expertise in custom steel machining. | High |

| Technology and Equipment | Modern machinery and technology used for precision machining. | High |

| Quality Control | Rigorous quality assurance processes to ensure consistency and reliability. | High |

| Pricing | Competitive pricing models to fit budget requirements without compromising quality. | Medium |

| Customer Support | Availability of customer service and support during the manufacturing process. | Medium |

| Lead Time | Timeframe from order placement to delivery of products. | Medium |

| Capabilities | Range of machining capacities and specialization in different materials. | High |

| Certifications | Relevant industry certifications and compliance with standards. | High |

When searching for the right manufacturer for custom steel machining solutions, evaluating their capabilities is crucial. Key factors to consider include the tools, technology, and expertise they possess. According to a recent report by Grand View Research, the global custom machining market is projected to reach $70.9 billion by 2025, highlighting the growing demand for precision machining services. Therefore, it's essential to partner with manufacturers who not only invest in state-of-the-art machinery but also continuously upgrade their technological capabilities to stay competitive.

In addition to sophisticated tools, the expertise of the workforce can significantly impact the quality of custom machining solutions. A survey conducted by the National Institute for Metalworking Skills (NIMS) indicates that companies that emphasize workforce training and development experience a 25% increase in operational efficiency. This statistic underscores the importance of selecting a manufacturer that values skilled labor, as their proficiency can lead to innovative solutions and superior machining results. By thoroughly assessing these factors, businesses can ensure they align with a manufacturer that meets their precise needs.

Effective communication is paramount when establishing a successful manufacturing partnership, especially in the realm of custom steel machining solutions. The complexity of this industry necessitates clarity and openness between manufacturers and their clients. This ensures that all specifications, timelines, and quality standards are well understood and met. By fostering an environment where open dialogue is encouraged, both parties can address potential challenges and align their expectations from the very beginning.

Moreover, as the manufacturing landscape continues to evolve with advancements such as Industry 4.0, maintaining strong lines of communication becomes even more critical. Organizations must be transparent about their capabilities, technologies, and workflows to create trust and streamline processes. Research underscores that efficient communication not only builds relationships but also enhances overall performance and innovation within the manufacturing sector. Emphasizing collaboration and teamwork will ultimately lead to better outcomes, enabling manufacturers to adapt quickly to changing demands and deliver exceptional custom machining solutions.

When exploring quality assurance practices in custom steel machining solutions, it’s crucial to consider the manufacturer’s certifications and quality control processes. A reliable manufacturer should have industry-standard certifications such as ISO 9001, which indicates a commitment to maintaining high-quality standards throughout production. Regular audits and inspections of processes ensure that every aspect of production meets specific quality criteria, minimizing defects and enhancing product reliability.

**Tip 1:** Always inquire about the manufacturer's quality assurance methods. Ask how they monitor their processes and what kind of testing is performed on the finished products. This information will give you insight into their dedication to quality.

Additionally, effective communication between you and the manufacturer plays a significant role in quality assurance. A responsive manufacturer can address potential issues promptly and make necessary adjustments during the production process. Ensuring that they have clear channels for feedback and support is essential in maintaining the desired standards.

**Tip 2:** Establish regular check-ins during the manufacturing process. This proactive approach helps identify any potential deviations from your specifications early on, ensuring that the final product meets your exact requirements.