- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

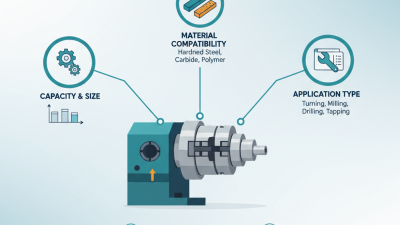

When embarking on the journey of lathe work, whether as a beginner or an advanced user, understanding the essential tooling for lathe is crucial for achieving precision and efficiency. Lathes, renowned for their versatility in shaping, cutting, and finishing materials, require various tools and attachments to optimize their capabilities. The right tooling not only enhances the quality of work but also significantly impacts the overall efficiency and safety of the machining process.

For beginners, navigating the myriad options available can be overwhelming. It is vital to comprehend the fundamental tools necessary for starting out, such as cutting tools, tool holders, and measuring devices. As users become more experienced, they can explore advanced tooling for lathe that offers greater control and versatility in various applications. This guide will provide insights into the essential tooling for lathe that every user should consider, along with practical tips for selection and usage. Whether you are just starting or looking to refine your skills, understanding these tools is key to mastering the art of lathe work.

When operating a lathe, safety is paramount. According to the Occupational Safety and Health Administration (OSHA), nearly 19% of workplace injuries are attributed to machinery, highlighting the importance of proper safety equipment. Essential safety gear includes protective eyewear, hearing protection, and appropriate clothing that is free of loose ends that could catch in moving parts. Using a face shield in addition to safety glasses is advisable, especially when dealing with high-speed tools, as small debris can cause serious injuries.

Tips: Always ensure your protective gear fits properly and is comfortable for prolonged wear, as this encourages consistent use. Establish a safety zone around your lathe to minimize distractions and avoid unnecessary accidents.

Another critical aspect of lathe safety is maintaining a clean workspace. The National Institute for Occupational Safety and Health (NIOSH) reports that cluttered work areas increase the likelihood of slips, trips, and falls. Regularly clearing away shavings and other debris will help maintain a safe environment, allowing for better visibility and access to emergency stops or shut-off switches.

Tips: Implement a routine maintenance schedule not only for the lathe itself but also for keeping the working area organized and clean, reinforcing a culture of safety. Encourage regular safety meetings to discuss practices and equipment checks.

When starting with lathe work, having the right tools is essential for both beginner and advanced users. For novices, certain basic lathe tools not only simplify the learning process but also enhance safety and accuracy. According to a recent report from the Association of Woodworking Professionals, approximately 70% of novice woodworkers indicate that having the appropriate tools significantly boosts their confidence and satisfaction in their projects. Among these tools, a set of high-quality chisels is fundamental, as they allow for more control over the shaping and smoothing processes.

In addition to chisels, a reliable parting tool should be at the forefront of every beginner's toolkit. The same report highlights that effective parting techniques are critical for creating clean transitions between different elements of a project. Furthermore, calipers and measuring tools are indispensable for ensuring precision, with studies showing that precise measurements reduce material waste by up to 15%, a crucial consideration for those looking to maximize efficiency in their craft. Other essential tools include a sturdy faceplate and drive centers, which facilitate a safer and more stable working environment on the lathe. By investing in these basic tools, beginners lay a solid foundation for a lifetime of crafting and mastering lathe techniques.

This chart illustrates the number of users for various essential lathe tools commonly used by both beginners and advanced users. It highlights the importance of having the right tools for effective woodworking and metalworking.

When it comes to advanced tooling techniques for experienced lathe users, the focus shifts from basic operation to mastering precision and efficiency. Skilled users often employ specialized tools to achieve intricate designs and tighter tolerances. One effective technique is the use of carbide-tipped tools, which offer enhanced durability and allow for high-speed machining without sacrificing tool life. Experienced users can also experiment with different tool geometries to refine their cutting processes, enabling them to tackle a diverse range of materials with ease.

Tips: Always ensure that your tooling is properly aligned and calibrated before starting a project. This not only improves the quality of the finished work but also minimizes wear on your machine and tools. Additionally, keeping a clean workspace and maintaining your tools can significantly extend their lifespan and improve your overall productivity.

Another advanced technique involves the use of CNC lathes with programmable features. This allows for repeated precision and the ability to create complex parts with high accuracy. Understanding G-code and mastering the software are essential steps in unlocking the full potential of your CNC lathe. Knowledge of advanced machining methods, such as interpolation and threading, can dramatically enhance your capabilities as a lathe user.

Tips: Regularly updating your skills through workshops or online courses can greatly benefit your technical knowledge and keep you abreast of the latest advancements in tooling techniques. Collaboration with other experienced users can also provide fresh insights and techniques that you may not have encountered before.

Maintaining lathe tools is crucial for both beginners and advanced users to ensure optimal performance and longevity. Regular maintenance practices not only enhance the lifespan of your tools but also improve precision and quality of work. According to industry reports, approximately 30% of tool wear can be mitigated through proper maintenance techniques. Tools that are well-maintained can also save users up to 20% in replacement costs over time, reinforcing the importance of adopting a routine maintenance schedule.

One essential maintenance practice is the routine cleaning of the lathe and its components. Keeping your lathe free from dust and debris minimizes the risk of wear and tear on both the machine and the tools used. Additionally, regularly lubricating moving parts can drastically reduce friction and prolong the machine's life. Inspecting for wear and tear, and promptly replacing any damaged parts, will also prevent larger issues down the road.

Tips: Always use appropriate cleaning agents that do not corrode metal surfaces. Implement a weekly check-up on your equipment, focusing on tool sharpness and machine alignment to identify potential issues before they escalate. Lastly, documenting maintenance schedules can be incredibly helpful, allowing users to track their tools' performance and condition effectively.

Lathe projects provide an excellent opportunity for both beginners and advanced users to enhance their skills while gaining a deeper understanding of the lathe's functions. One of the most common projects for novices is creating simple spindles, which allows them to practice basic turning techniques and learn about tool angles and feed rates. As users become more confident, they can progress to crafting intricate bowls or decorative items, which require a blend of creativity and technical skill. These projects not only improve hand-eye coordination but also foster a problem-solving mindset as users work through challenges that arise during the turning process.

For more advanced users, undertaking a project such as building a custom tool holder or a complex woodworking piece can push their limits and expand their knowledge of lathe operations. This type of work demands precision and experimentation with different cutting tools, feeds, and speeds, leading to a better grasp of material properties and mechanical principles. Engaging in such projects invites users to explore innovative techniques and refine their craftsmanship, ultimately resulting in enhanced productivity and satisfaction in their lathe work. Each completed project, no matter the complexity, contributes to a growing repository of knowledge and mastery, setting the stage for even more ambitious endeavors in the future.