- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the competitive world of manufacturing, efficient "Processing Of Parts" is crucial. Industry expert, Dr. Emily Johnson, who specializes in manufacturing efficiency, emphasizes, “Streamlining processes can significantly reduce waste and enhance productivity.” Her insights guide many in the field.

Understanding the nuances of part processing can transform operations. It's not just about speed; quality and precision matter too. Many companies overlook this balance, leading to costly errors. A wrong part can halt production. Therefore, reflecting on current practices is vital.

Mistakes are part of progress. For example, some manufacturers may prioritize volume over precision. This can result in high rejection rates. It's essential to analyze each process. Adjustments in techniques can lead to better outcomes. Ultimately, mastering the "Processing Of Parts" requires ongoing evaluation and adaptation.

Efficient parts processing is vital for manufacturing. According to a recent industry report, businesses that optimize their parts processing can see a productivity increase of up to 30%. However, many companies struggle with basic inefficiencies in their operations.

One key factor is the layout of the workspace. A cluttered area can slow down processes, leading to wasted time searching for tools or materials. A study found that 40% of workers spend time looking for misplaced items. Streamlining the workspace can significantly improve efficiency.

Another crucial aspect is employee training. Well-trained workers tend to be more productive, while a lack of proper training can lead to higher error rates. Statistics reveal that companies investing in employee skill development report up to a 20% reduction in mistakes. Regular training sessions should be a priority.

Tracking progress through metrics can reveal areas needing improvement. Implementing these strategies might require time and effort, but the long-term benefits are undeniable.

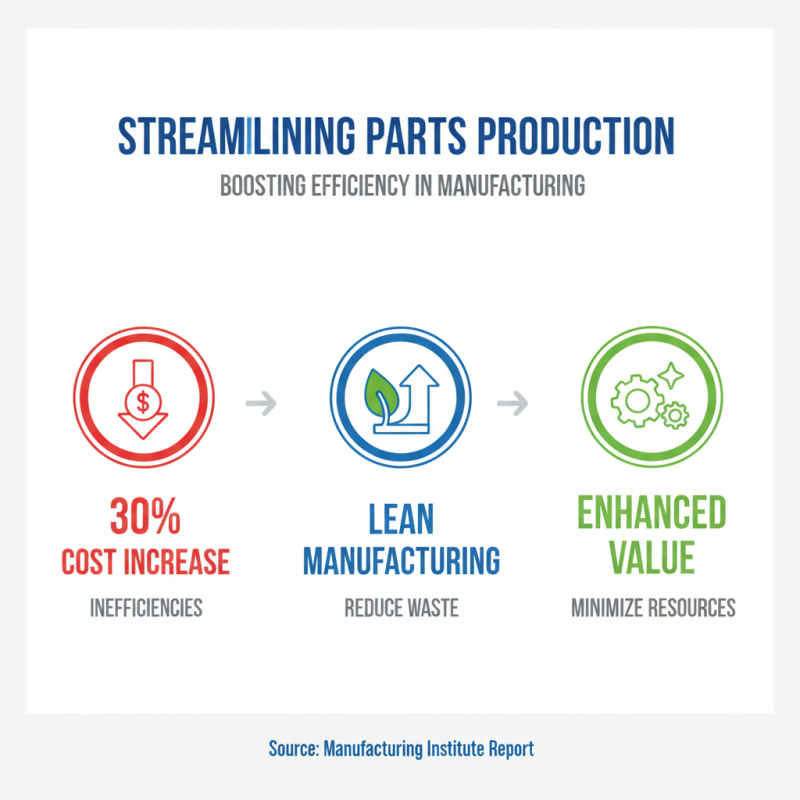

In today's fast-paced manufacturing landscape, streamlining parts production is critical. A recent report by the Manufacturing Institute noted that inefficiencies can lead to up to a 30% increase in operational costs. Implementing lean manufacturing principles can help reduce waste. This approach focuses on enhancing value while minimizing resources.

Automation plays a vital role in optimizing production workflows. According to the World Economic Forum, companies that integrate automation can reduce lead times by as much as 40%. While automation is efficient, it also presents challenges. For instance, improper implementation may lead to equipment malfunctions or bottlenecks. Operator training is essential, yet often overlooked.

Another crucial technique is process mapping. This method visualizes workflow and identifies pain points. A study indicated that organizations using process mapping see a 25% improvement in productivity. However, mapping requires ongoing assessments to be effective. Regular reviews help teams adapt to changing demands. Companies should embrace a culture of continuous improvement to fully realize benefits.

Technology plays a vital role in enhancing parts processing speed. Automation is at the forefront of this transformation. According to a 2021 report by IndustryWeek, businesses that have integrated automation have seen a 30% increase in throughput. This change often results in more efficient workflows. The precision of automated systems reduces human error, leading to fewer reworks.

Moreover, data analytics offers insights that can optimize production lines. A Deloitte survey indicates that 60% of manufacturers utilize data analytics for process improvement. However, a significant number also face challenges in implementing these technologies. Many teams struggle with data overload. They often lack the skills to analyze the information effectively.

Not all technological solutions guarantee success. Some companies invest heavily in the latest machinery without clear strategies. This can lead to underperformance. It’s crucial to align technology with specific goals. The right tools, paired with a solid plan, can revolutionize parts processing.

| Technology | Description | Efficiency Improvement (%) | Implementation Cost ($) |

|---|---|---|---|

| Automated Cutting Machines | Precision cutting of parts using CNC technology. | 25% | 15000 |

| 3D Printing | Rapid prototyping and complex part manufacturing. | 40% | 25000 |

| Robotics | Automated assembly lines reducing labor costs. | 35% | 50000 |

| IoT Integration | Smart monitoring of production processes. | 30% | 20000 |

| AI and Machine Learning | Predictive maintenance and quality control. | 45% | 30000 |

Quality control is crucial in parts processing. It ensures that every component meets the required standards. Beginning with the inspection of raw materials is essential. Look for defects before production begins. A single flawed piece can lead to bigger issues down the line.

During processing, implement regular checks. Use simple tools like calipers and gauges for measurements. It helps catch inconsistencies early. Workers should be trained to identify defects. However, even with training, mistakes may happen. Encourage an environment where mistakes are discussed openly. This facilitates learning and improvement.

Final inspections should be thorough. Inspect the parts visually and mechanically. Document any issues for future reference. Even the best systems can miss things. Sometimes, human error can creep in unnoticed. Reflection on these errors is vital for growth. Emphasize continuous improvement in quality control practices.

Efficient resource management is vital in parts processing. It can drive productivity and reduce costs significantly. According to a 2022 industry report, companies that optimized resource allocation saw a 30% increase in output. This highlights the importance of evaluating workflows and reducing waste.

Identifying bottlenecks is crucial. Some processes may take longer than expected. Implementing a lean management approach can help. Companies have reported up to 25% time savings by streamlining operations. Regularly reviewing inventory levels also ensures that materials are always available. This prevents delays and improves overall efficiency.

However, there are challenges. Employees may resist changes, fearing increased workload. Additionally, technology investments can be daunting. It's essential to consider both human factors and technical capabilities when optimizing resources. Striking a balance can lead to successful outcomes in parts processing.