- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

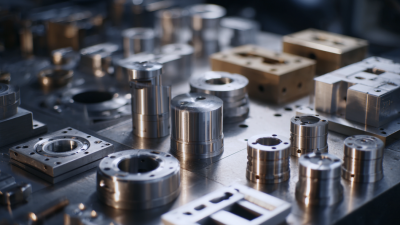

In the rapidly evolving landscape of modern manufacturing, the Processing Of Parts has emerged as a pivotal factor that determines operational efficiency and product quality. According to a report by McKinsey & Company, manufacturers who optimize their parts processing can reduce lead times by up to 50%, significantly enhancing their competitiveness in a global market. Furthermore, the World Economic Forum highlights that advanced manufacturing technologies can lead to a 20-25% increase in productivity. As industries shift towards more automated and streamlined processes, understanding the essential steps involved in the Processing Of Parts is crucial for companies aiming to stay ahead. This blog will explore eight fundamental strategies that not only improve efficiency but also empower manufacturers to meet the ever-increasing demands of consumers while maintaining high standards of quality and cost-effectiveness.

Digital transformation is revolutionizing manufacturing processes by integrating advanced technologies and data-driven strategies. At the heart of this transformation lies the automation of workflows, which enhances efficiency and reduces the risk of human error. By utilizing robotics and AI, manufacturers can streamline production lines, enabling real-time data collection and analysis. This leads to more informed decision-making and the ability to predict maintenance needs, rather than responding to machine failures reactively.

Moreover, embracing IoT (Internet of Things) in manufacturing facilitates seamless communication between machines and systems. Through embedded sensors, manufacturers gain insight into each stage of the production process, resulting in better tracking of parts and materials. This connectivity fosters a proactive approach to inventory management and supply chain logistics, ensuring optimal resource allocation and minimizing downtime. As companies adopt these key principles of digital transformation, they position themselves for greater agility and competitiveness in the ever-evolving manufacturing landscape.

In the realm of modern manufacturing, leveraging data analytics has become a pivotal strategy for optimizing parts processing efficiency. With the rapid advancements in technology, manufacturers can capitalize on data-driven insights to streamline operations, reduce waste, and enhance overall productivity. By analyzing historical data and real-time metrics, organizations can pinpoint inefficiencies in their processes and implement targeted improvements that align with business objectives.

The integration of data analytics into parts processing not only boosts operational efficiency but also empowers manufacturers to respond swiftly to market demands. By utilizing advanced algorithms and machine learning techniques, companies can predict maintenance needs, forecast supply chain disruptions, and optimize inventory levels. For instance, by harnessing AI-driven insights, manufacturers can automate processes, enabling a faster turnaround time while maintaining high standards of quality. This strategic approach to parts processing serves as a catalyst for innovation, positioning companies to thrive in an increasingly competitive landscape.

In modern manufacturing, the integration of automation into production lines has become a crucial factor for enhancing efficiency. By incorporating advanced technologies such as robotics, IoT, and AI, manufacturers can streamline operations and reduce the reliance on manual labor. Automation facilitates faster processing of parts, resulting in shorter lead times and increased output. Additionally, the capability of machines to operate continuously without fatigue ensures that production lines maintain a steady pace, minimizing bottlenecks and delays.

Moreover, the data-driven insights generated by automated systems provide manufacturers with critical information on performance metrics, enabling them to identify areas for improvement quickly. This intelligence allows for proactive maintenance, optimizing equipment performance and avoiding costly downtimes. Ultimately, the seamless integration of automation not only enhances operational efficiency but also promotes a culture of innovation and agility within manufacturing environments, positioning companies to effectively meet the ever-evolving demands of the market.

In today's fast-paced manufacturing landscape, the integration of Internet of Things (IoT) technologies is revolutionizing the way parts are processed. IoT enables real-time monitoring and control, providing manufacturers with instantaneous data insights that enhance operational efficiency. By equipping machinery and equipment with smart sensors, manufacturers can track the performance and health of their assets, allowing for predictive maintenance and minimizing unexpected downtimes. This data not only streamlines processes but also empowers decision-makers to respond quickly to changing production demands.

In addition to monitoring machinery, IoT technologies facilitate seamless communication across the supply chain. Connected devices can send alerts regarding inventory levels, production schedules, and quality control issues, ensuring that every aspect of manufacturing operates in harmony. With advanced analytics, manufacturers can identify bottlenecks and inefficiencies, leading to optimized workflows and reduced operational costs. Embracing IoT solutions not only enhances productivity but also fosters a culture of continuous improvement, positioning companies at the forefront of modern manufacturing innovation.

Efficient processing of parts in modern manufacturing hinges on the adoption of best practices that leverage advanced technologies and methodologies. According to a report by the McKinsey Global Institute, manufacturing companies that implement Industry 4.0 technologies can improve productivity by up to 30%. This leap is often attributed to the integration of IoT, AI, and data analytics, which allows for real-time monitoring of production processes and more informed decision-making.

Another critical strategy is the adoption of lean manufacturing principles. A study by the Lean Enterprise Institute found that companies implementing lean practices experience a 25% reduction in waste and a 15% increase in production efficiency. By focusing on value-adding activities and eliminating non-essential processes, manufacturers can create more streamlined operations. Additionally, fostering a culture of continuous improvement among employees can drive innovation and adaptability, ensuring that manufacturers stay competitive in a rapidly evolving market.