- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the ever-evolving landscape of manufacturing, efficiently managing the "Processing Of Parts" remains a critical challenge. John Smith, an expert in industrial engineering, emphasizes, “Efficient part processing can transform production capabilities.” This highlights the importance of mastering techniques in the industry.

Many companies still struggle with this aspect. They find themselves overwhelmed by the volume of parts needing processing. Inefficiencies creep in, leading to production delays and increased costs. For example, a minor setback in one area can cascade through the workflow. Without a streamlined approach, these issues often remain unresolved.

Reflection is essential in this domain. Organizations should assess their current strategies and look for forgotten areas that need attention. The processing of parts is not just about speed. It's also about precision and quality. Balancing these elements can lead to breakthroughs in operational efficiency. Only by acknowledging imperfections can meaningful improvements be made in the processing of parts.

In manufacturing, efficiently managing parts processing is vital. One effective strategy is implementing lean manufacturing principles. This approach helps eliminate waste. It streamlines the entire production line. For instance, reducing excess inventory can significantly cut costs. Lower inventory means less space is needed, leading to a more organized workspace.

Another tactic is to use data analytics. By analyzing processing times and bottlenecks, manufacturers can identify inefficiencies. For example, if a particular machine consistently delays output, it might need upgrades or more maintenance. However, relying solely on data can be misleading. Data can sometimes present a false sense of security, masking underlying issues.

Lastly, fostering communication among team members promotes efficiency. Regular updates allow everyone to stay informed. This collaboration helps workers address problems early. Yet, this requires a culture of openness. Some teams may struggle with this. Not every organization fosters a healthy communication environment. Emphasizing these aspects can drive significant improvements in parts processing.

The world of part processing is rapidly evolving. Key technologies are introducing remarkable changes. Automation tools streamline workflows, reducing manual tasks. This maximizes efficiency on production lines. Robotics now handle repetitive jobs. They boost precision and speed, but implementation can be challenging. Companies often face a steep learning curve.

Data analytics plays a critical role too. Analyzing production data helps identify bottlenecks. It allows managers to make informed decisions. Yet, companies sometimes overlook the importance of data integrity. Poor data can lead to flawed conclusions. It’s vital to address this issue for optimal outcomes.

Cloud-based systems facilitate real-time collaboration. This promotes seamless communication across teams. However, not all organizations are ready for this transition. Resistance to change can slow down progress. Training and support become essential during this shift. Embracing new technologies is crucial but not always easy. Continuous improvement and adaptability are needed.

Lean manufacturing has profoundly changed parts processing. By minimizing waste, companies improve efficiency and reduce processing times. According to a report by the Lean Enterprise Institute, organizations can achieve up to a 50% reduction in lead times through lean practices.

Adopting just-in-time (JIT) principles significantly impacts parts processing. JIT allows for the delivery of components exactly when they are needed. A study by the Society of Manufacturing Engineers found that implementing JIT can cut inventory costs by as much as 30%. This approach reduces the time parts spend in storage. However, it also requires precise coordination. Many companies struggle with fluctuating demand, leading to stockouts or excess inventory.

Visual management tools, like Kanban boards, have improved transparency in processing times. These tools help teams identify bottlenecks quickly. Yet, many organizations report challenges in maintaining consistent use of these systems. Continuous training is necessary, but often overlooked. The ability to adapt lean strategies varies between companies. Some achieve excellent results, while others find themselves stalled by resistance to change.

| Part Type | Processing Time (Hours) | Lean Implementation Status | Cycle Time Improvement (%) | Lead Time Reduction (Days) |

|---|---|---|---|---|

| Gear | 5 | Implemented | 15% | 3 |

| Bracket | 3 | Not Implemented | 0% | 0 |

| Plate | 2 | Implemented | 20% | 2 |

| Screw | 4 | In Progress | 10% | 1 |

| Nut | 1 | Implemented | 25% | 5 |

In today's fast-paced manufacturing environment, efficient parts management is crucial. A data-driven approach enables better tracking and inventory control. By leveraging technology, businesses can significantly enhance their operational efficiency. Using software can help monitor parts in real-time. This allows for accurate inventory counts and reduces human error.

Tips for effective tracking include establishing a centralized database. This serves as a single source of truth for all parts. Regularly updating this database can prevent discrepancies. Another tip is to implement barcode or RFID systems. These technologies simplify tracking and enhance visibility across the supply chain.

While these strategies can streamline processes, challenges persist. Data accuracy relies on consistent input, which can vary. Many organizations struggle with outdated systems that impede progress. Continuous training for staff is vital to overcome these barriers. Additionally, fostering communication among teams can help identify inefficiencies. Reflecting on the existing processes is necessary for sustainable improvement.

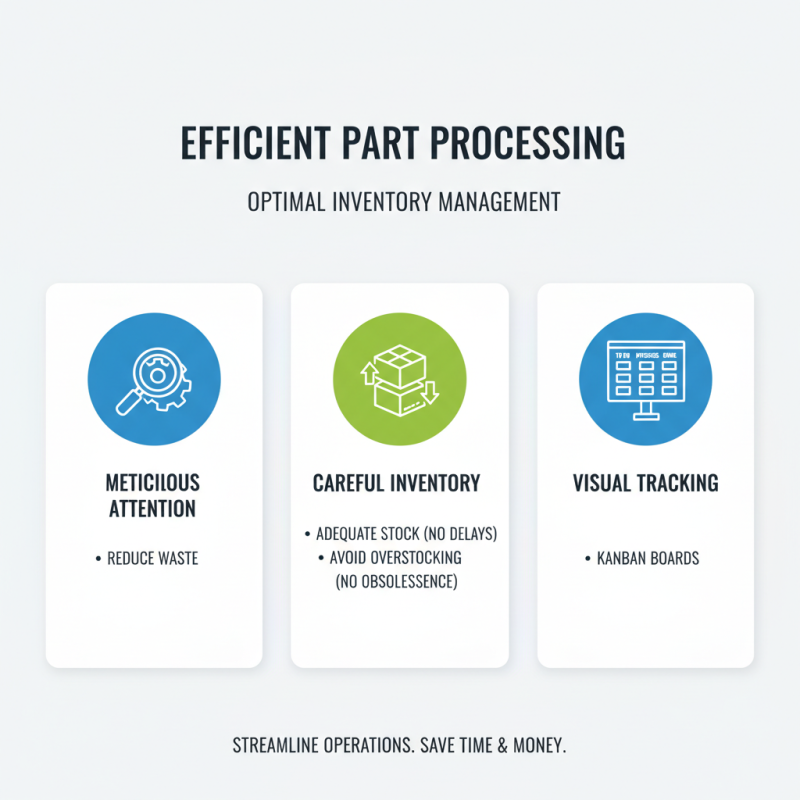

Efficient part processing requires meticulous attention to detail. One way to reduce waste is through careful inventory management. Ensure that materials are adequately stocked to prevent delays but avoid overstocking that leads to obsolescence. Visual tools like Kanban boards can simplify tracking and help maintain optimal levels.

Improving quality often means revisiting existing processes. Invest time in training operators. They should understand the machinery and materials they are working with. Regularly scheduled maintenance can also prevent unexpected breakdowns, which waste both time and resources. Remember, human errors occur, so implementing checklists can help minimize mistakes.

Monitoring the cycle times of each process step is crucial. Identify bottlenecks and assess their causes. This might require revising workflows or redistributing tasks among team members. Not all workers are equally efficient, and this can lead to inconsistencies in part quality. Gathering feedback can direct improvement efforts more effectively.