- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

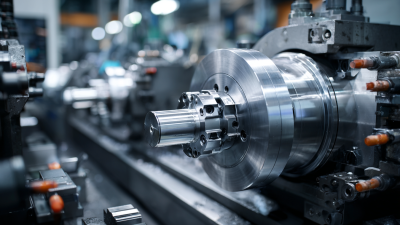

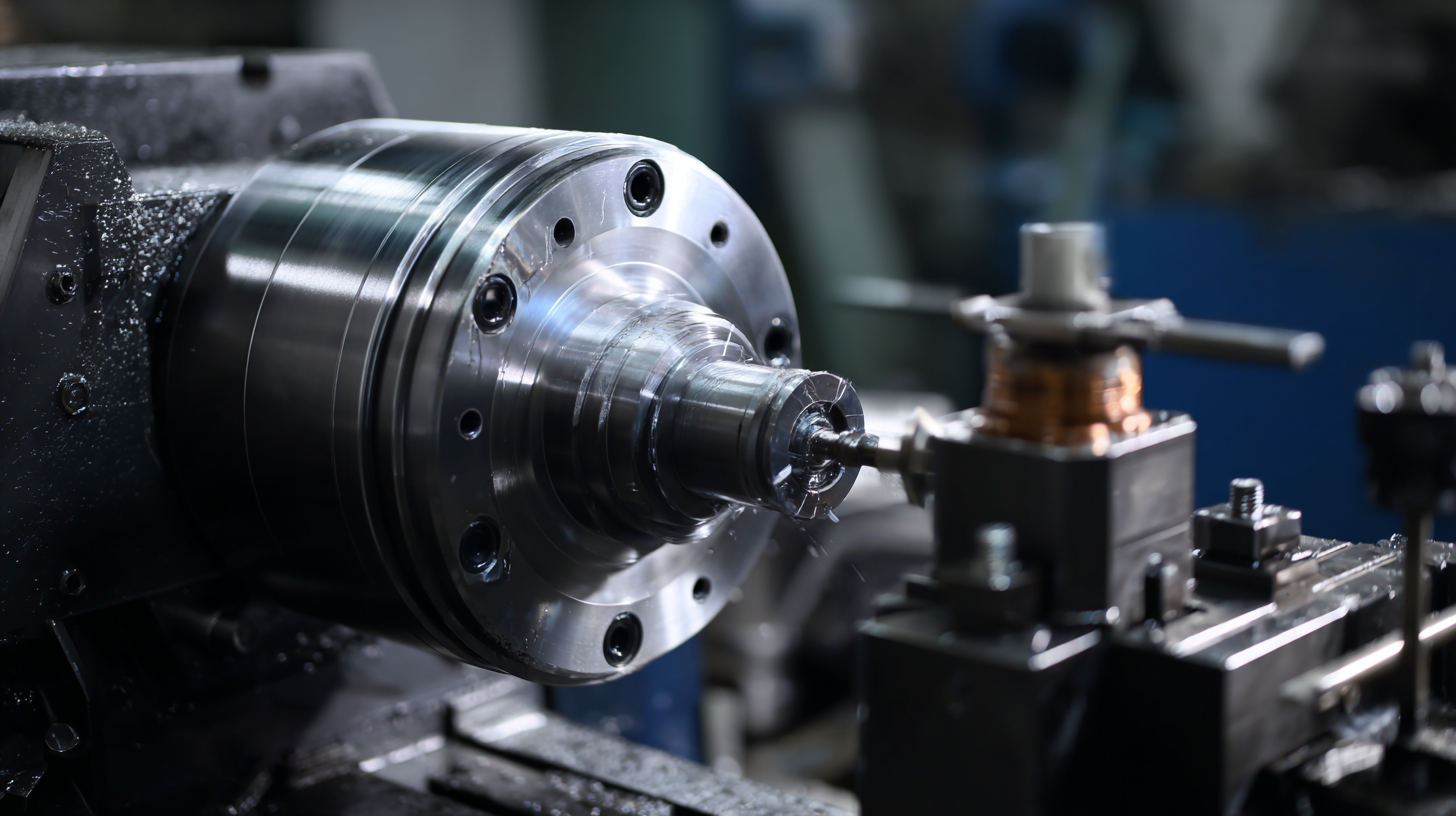

In today's rapidly evolving industrial landscape, the significance of Custom Metalworking cannot be overstated. This innovative approach to manufacturing not only enhances precision and efficiency but also catapults various industries into a new era of productivity. By tailoring metal components to specific requirements, custom metalworking plays a pivotal role in meeting the unique demands of contemporary manufacturing processes. Whether in automotive, aerospace, or electronics, the ability to produce bespoke metal parts allows companies to maintain a competitive edge and respond swiftly to changing market needs.

In today's rapidly evolving industrial landscape, the significance of Custom Metalworking cannot be overstated. This innovative approach to manufacturing not only enhances precision and efficiency but also catapults various industries into a new era of productivity. By tailoring metal components to specific requirements, custom metalworking plays a pivotal role in meeting the unique demands of contemporary manufacturing processes. Whether in automotive, aerospace, or electronics, the ability to produce bespoke metal parts allows companies to maintain a competitive edge and respond swiftly to changing market needs.

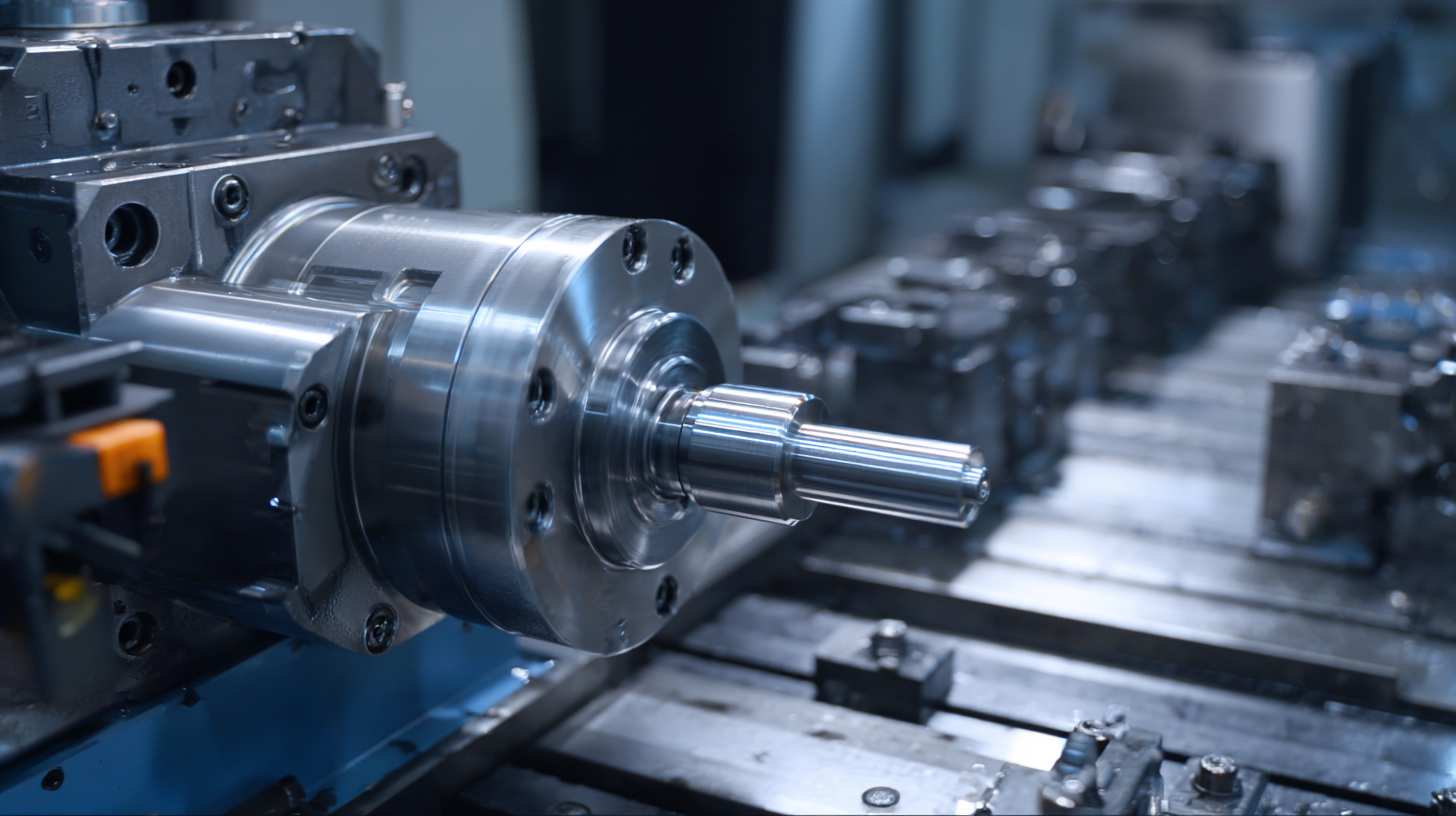

Custom Metalworking goes beyond mere fabrication; it embodies a transformative methodology that redefines operational capabilities. As manufacturers strive for excellence, the integration of advanced technologies such as CNC machining and additive manufacturing in custom metalworking processes has revolutionized the way metal components are designed and produced. This not only leads to improved product quality but also significantly reduces lead times and material waste, promoting sustainability within the production cycle. As industries embrace this cutting-edge approach, the future of manufacturing is poised for unprecedented growth and innovation, driven by the versatility and adaptability of Custom Metalworking.

Custom metalworking is at the forefront of modern manufacturing, significantly enhancing production efficiency through innovative techniques. These techniques enable manufacturers to produce high-quality components tailored to specific requirements rapidly. According to recent industry reports, the global custom metalworking market is projected to grow at a CAGR of over 7% from 2023 to 2030, driven by advancements in automation and digital technologies.

Recent developments highlight the shift from traditional manufacturing methods to intelligent systems, where data-driven decision-making is key. Companies are increasingly utilizing digital twins, allowing for real-time monitoring and optimization of production processes. This transition is vital for small to medium-sized enterprises (SMEs) striving for improved productivity and sustainability, as they embrace these cutting-edge technologies to thrive in a competitive landscape.

**Tips:** To enhance efficiency, consider implementing ERP systems that integrate various aspects of manufacturing. This can streamline operations and reduce bottlenecks. Additionally, investing in training for employees on new technologies can foster a culture of innovation and adaptability, critical for long-term growth in the ever-evolving industrial sector.

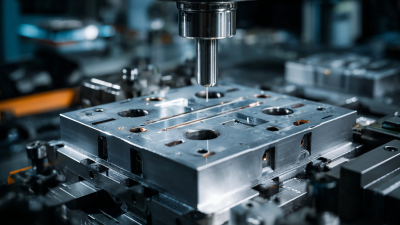

In today’s rapidly evolving manufacturing landscape, precision metal fabrication plays a crucial role in modern supply chains, driving efficiency and innovation across various industries. According to industry reports, the North American metal fabrication market is projected to grow at a compound annual growth rate (CAGR) of 5.75% from 2025 to 2033, highlighting the increasing demand for customized metal solutions. The surge in interest was evident at recent industry events like FABTECH, where over 40,000 participants gathered, sharing insights amidst ongoing concerns about trade and inflation.

Moreover, innovations in CNC machining and die casting are positioning manufacturers to meet the complex demands of modern production. As manufacturers invest in advanced production capabilities, they also focus on smart controls to enhance operational efficiency in sectors such as HVAC. The push for sustainability and performance in manufacturing necessitates a re-evaluation of supply chains, as companies explore strategic approaches from raw materials to finished products, emphasizing the importance of robust and resilient frameworks to navigate the challenges of global competition and market fluctuations.

The custom metalworking industry is at the forefront of integrating sustainability practices that not only benefit the environment but also enhance financial performance. As the global lubricants market is projected to reach USD 204.10 billion by 2030, manufacturers are increasingly adopting eco-friendly alternatives that reduce emissions and waste. Sustainable manufacturing processes, such as precision machining and the use of recyclable materials, are gaining traction as they contribute to lower production costs and resource conservation.

Moreover, companies that implement sustainable practices often see an increase in revenue. For instance, businesses that focus on reducing their carbon footprint through innovative techniques report improved customer loyalty and market competitiveness. The transition towards greener operations leads to operational efficiency, where the reduction in waste translates into significant cost savings. This shift not only aligns with global efforts to combat climate change but also positions custom metalworking as a pivotal player in the broader manufacturing landscape, illustrating that environmental responsibility can coexist with industrial growth.

Emerging technologies are rapidly transforming the metalworking industry, driving innovation and increasing efficiency in modern manufacturing. According to a report by MarketsandMarkets, the global metalworking market is projected to reach $100 billion by 2027, growing at a CAGR of 5.1%. This growth is closely tied to advancements such as additive manufacturing, robotics, and automated machining processes, which enhance precision and reduce waste.

One standout technology is the integration of artificial intelligence (AI) in metalworking processes. AI-driven analytics allow manufacturers to optimize production schedules and reduce downtime, ultimately saving time and costs. A study by Deloitte found that incorporating AI can lead to a 20-30% increase in productivity. As companies adopt these technologies, they are not only improving output but also paving the way for smarter, more sustainable manufacturing practices.

**Tips:** For manufacturers looking to adopt these emerging technologies, start with pilot programs that test AI and automation in small-scale projects. This allows you to understand the impact on operations without a significant upfront investment. Additionally, invest in training your workforce to adapt to these advanced technologies, ensuring that your team can fully leverage their potential.

Custom metalworking has become a cornerstone in various industries, propelling advancements in manufacturing. One standout example is the aerospace sector, where precise components are crucial for safety and performance. According to the Aerospace Industries Association, the U.S. aerospace industry generated over $246 billion in revenue in 2022, with custom metalworking playing a vital role in producing lightweight yet durable parts that meet stringent aerospace standards. Companies like Boeing and Airbus leverage custom fabrication techniques to reduce weight while maintaining structural integrity, enhancing fuel efficiency and overall performance.

In healthcare, custom metalworking is also making significant strides. Medical devices often require tailor-made components to ensure compatibility and effectiveness. A report by Research and Markets indicates that the global medical device market is expected to reach $612 billion by 2025, with custom metalworking providing innovative solutions for producing specialized surgical instruments and implants. Companies that invest in custom metal solutions are better positioned to respond to rapid technological advancements and regulatory changes.

**Tips:** When exploring custom metalworking options, businesses should prioritize collaboration with experienced manufacturers to optimize design processes. Additionally, assessing the latest technologies in CNC machining and 3D printing can significantly enhance production efficiency and product quality. It’s essential to remain adaptable and open to innovative solutions that can drive competitive advantage in today's fast-paced market.