- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

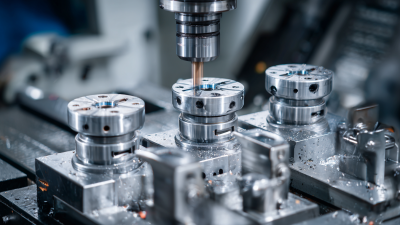

Compressed Air Supply systems are vital to many industrial processes, acting as the backbone for a wide range of applications from powering tools to controlling machinery. According to the Compressed Air and Gas Institute (CAGI), approximately 70-80% of all manufacturing facilities utilize compressed air in some form, making it one of the most common energy sources in the industrial sector. However, with great reliance comes the potential for significant operational challenges. An industry report by the U.S. Department of Energy highlights that up to 30% of energy consumed in compressed air systems is wasted due to leaks and inefficiencies. These challenges necessitate a thorough understanding and regular assessment of compressed air supply systems. This blog will provide a detailed checklist of common issues encountered, aiming to equip industry professionals with the insights needed to optimize performance, reduce energy costs, and prolong equipment lifespan.

Regular maintenance of compressed air supply systems is crucial for ensuring optimal performance and extending the lifespan of equipment. With the global pneumatic tools market expected to reach a value of $15.42 billion by 2024 and a projected compound annual growth rate (CAGR) of 1.77% until 2033, the demand for efficient and reliable compressed air systems is on the rise. Neglecting maintenance can lead to inefficiencies, increased operational costs, and unplanned downtime, which can significantly impact productivity.

In this context, conducting regular inspections and preventive maintenance on air compressors and related components is not just a best practice but a necessity. Routine tasks such as checking filters, monitoring pressure levels, and ensuring proper lubrication can drastically reduce the risk of system failures. Additionally, as more industries turn to pneumatic tools for their operations, the importance of maintaining an efficient air supply system becomes even more evident, underpinning both performance and profitability in an increasingly competitive market. By investing in proper maintenance, businesses can safeguard their operations and stay ahead in a growing sector.

| Issue | Description | Impact | Recommended Maintenance |

|---|---|---|---|

| Air Leaks | Unintended openings in the air line that allow compressed air to escape. | Increased energy costs and reduced efficiency. | Regularly inspect and repair air lines and connections. |

| Moisture Build-Up | Condensation in the air lines which can lead to corrosion. | Equipment damage and impaired performance. | Install moisture separators and regularly drain the system. |

| Filter Clogging | Accumulation of debris and contaminants in the air filters. | Reduced airflow and increased energy consumption. | Change filters regularly based on usage and manufacturer guidelines. |

| Pressure Drops | Insufficient pressure due to demand exceeding supply capabilities. | Inconsistent tool performance and productivity loss. | Monitor usage patterns and ensure adequate compressor capacity. |

| Compressor Overheating | Excessive heat resulting from prolonged operation or blocked vents. | Potential compressor failure and costly repairs. | Ensure cooling systems are functioning and clean vents regularly. |

Air quality plays a critical role in the efficiency of compressed air supply systems. Common air quality issues, such as contamination and moisture, can significantly hinder system performance. Contaminants like dirt and oil can lead to equipment wear and increased energy consumption, making it imperative for industry professionals to regularly monitor and enhance the quality of the compressed air they supply.

In fact, studies show that improved air quality can not only extend the lifespan of machinery but also reduce operational costs, ultimately contributing to a more efficient system.

Moreover, the implications of air quality extend beyond industrial settings. With billions still breathing unhealthy air, as highlighted by WHO data, the impact on public health cannot be overstated. Countries that have successfully tackled air pollution have reported significant improvements in overall health metrics, including a notable decrease in suicide rates linked to better air quality. Thus, addressing air quality issues is not only vital for machinery efficiency but also essential for fostering a healthier population and a more productive workforce.

Pressure drops in compressed air lines can significantly impact system efficiency and performance. Identifying the source of these drops is essential for maintaining optimal air supply. Common causes include improper sizing of pipes, leaks, and blockages. Regular inspections and monitoring can help detect these issues early, ensuring your compressed air supply remains consistent and reliable.

Tip: Always aim for the right pipe diameter. Oversized pipes can lead to increased air velocity, while undersized pipes can cause significant pressure drops. Conduct a flow analysis to determine the ideal size for your system.

Another crucial aspect to address is the presence of moisture and contaminants in the air lines, which can lead to corrosion and reduced efficiency. Installing moisture traps and filters can help mitigate these risks.

Tip: Implement a routine maintenance schedule that includes checking filters and condensate drains. Cleaning and replacing these components regularly will help maintain pressure levels and extend the life of your compressed air system.

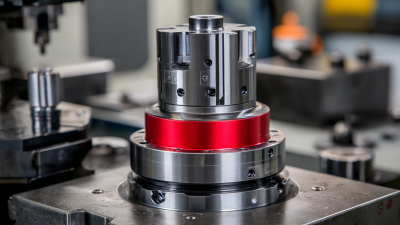

In compressed air supply systems, proper filtration and drying are crucial components that significantly enhance system performance. Contaminants such as dirt, moisture, and oils can infiltrate the air supply and lead to various operational issues, including equipment wear, reduced efficiency, and increased maintenance costs. Filtration systems serve to remove these unwanted particles, ensuring that the compressed air is clean and suitable for use in pneumatic applications. By implementing both primary and secondary filters, facilities can effectively safeguard their machinery, extending its lifespan and maintaining optimal performance levels.

Moreover, the drying process is equally essential in maintaining air quality. Moisture in compressed air can result in detrimental effects like corrosion, blockages, and even failure of downstream equipment. Using desiccant dryers or refrigerated dryers, businesses can achieve a specific dew point, eliminating moisture before it can cause harm. This commitment to proper air treatment not only improves system reliability but also enhances energy efficiency. In sum, investing in robust filtration and drying solutions is vital for any organization looking to optimize its compressed air supply system, reduce operational downtime, and ultimately save on costs.

This chart illustrates the impact of various issues on compressed air system performance, including filtration and drying effectiveness. The data represents the percentage of performance degradation associated with each issue.

Compressed air supply systems are integral to many industrial operations, yet they often face a variety of challenges that can lead to inefficiencies and increased costs. Addressing these common issues not only improves system performance but also enhances productivity. Implementing cost-effective solutions can significantly reduce downtime and operational expenses.

One key tip is to regularly perform maintenance checks on your air compressors and related equipment. Neglecting maintenance can lead to energy losses and unexpected breakdowns. Simple tasks, such as replacing air filters and inspecting hoses, can help maintain optimal performance. Additionally, consider using energy-efficient compressors that adjust to demand, ensuring you only use the energy necessary for your operations.

Another effective solution is to review your piping and distribution system for leaks and inadequate sizing. Air leaks can account for nearly 30% of compressed air usage, making them a major focus for cost savings. Seal leaks promptly and ensure that your piping is correctly sized to minimize pressure drops. By optimizing the air supply system, you not only enhance efficiency but also contribute to a more sustainable operation.