- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

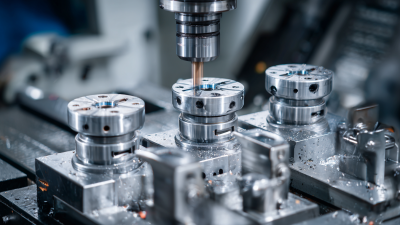

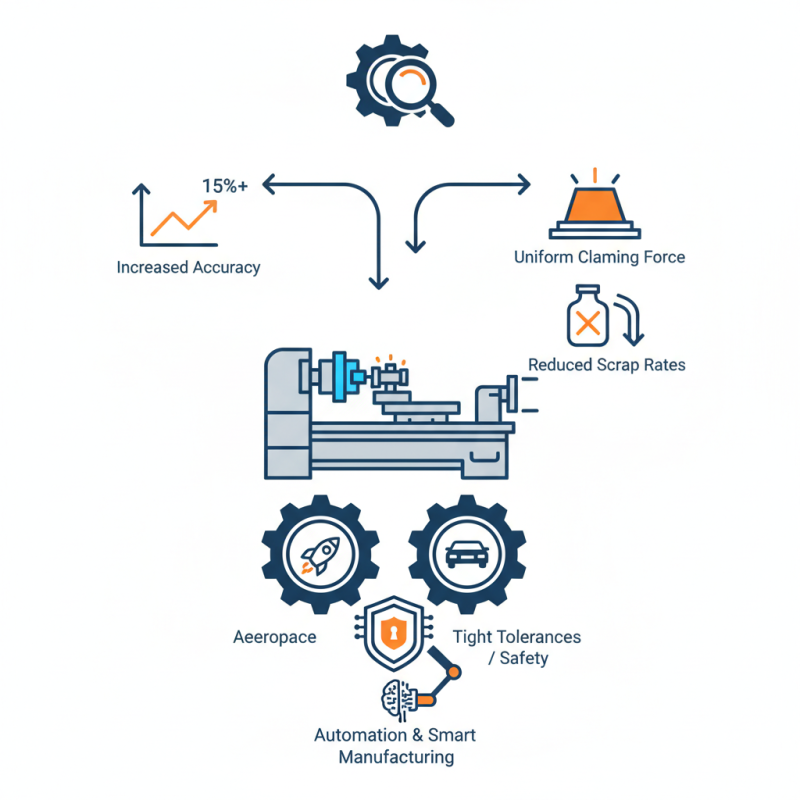

Precision machining demands the highest standards. Among the many tools in a machinist's arsenal, "Collets For Lathe" play a critical role. Studies show that using precision collets can increase machining accuracy by over 15%. They secure workpieces with minimal runout. This is crucial, especially in high-speed applications where even slight deviations can lead to costly errors.

Collets provide uniform clamping force. This ensures that workpieces remain stable during machining processes. Industry reports indicate that improper workholding can lead to a significant increase in scrap rates. The ability to maintain tight tolerances is essential in fields such as aerospace and automotive. These sectors rely on exact specifications for safety and performance.

Yet, not every lathe operator fully appreciates the value of collets. Some may overlook their benefits, opting for less precise alternatives. This oversight can result in diminished output quality and increased waste. As the industry moves towards automation and smarter manufacturing, the significance of collets cannot be understated. Emphasizing precision is key for future success.

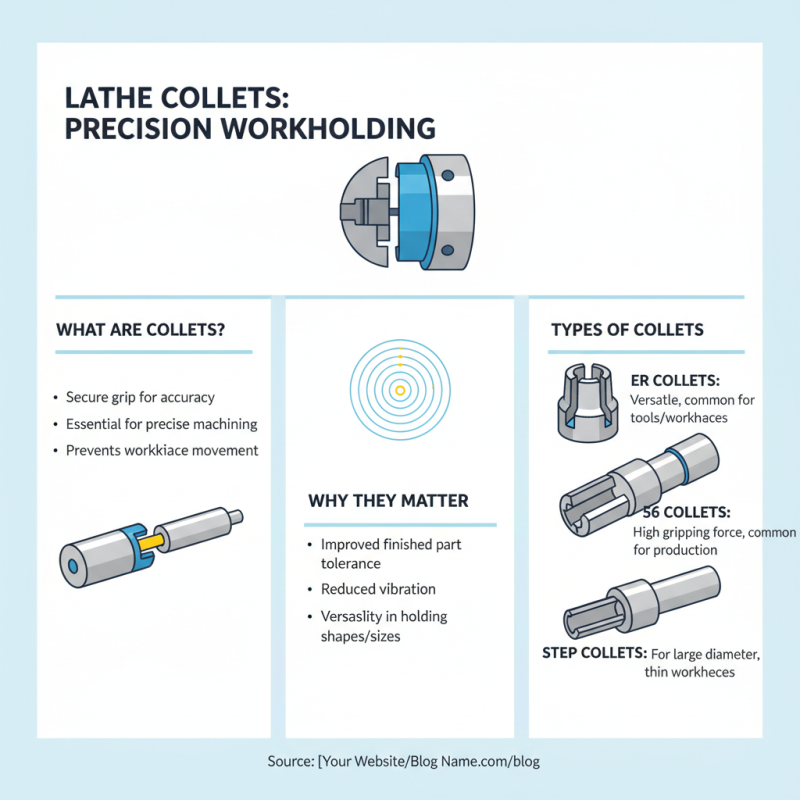

Collets play a vital role in lathe operations. They are precision devices that hold tools or workpieces securely. Their design allows for minimal run-out, which is crucial for accurate machining. According to a report by the International Journal of Advanced Manufacturing Technology, high precision in machining can increase the final product's quality by up to 30%. This highlights the significance of using collets.

The function of collets lies in their ability to grip various shapes and sizes. They ensure a tight fit without damaging materials. This adaptability is beneficial in various industries like aerospace and automotive. Often, lathe operators may neglect the importance of a proper collet. If a collet is worn or misaligned, it can lead to significant machining errors. The Precision Metalforming Association notes that improper clamping can lead to scrap rates exceeding 15%.

Operators must also consider material selection for collets. Different materials offer varying gripping forces and resistance to wear. However, not all collets are the same. A poorly chosen collet may loosen during operation, leading to inconsistent results. Continuous training and awareness can bridge this knowledge gap, fostering better machining practices. Precision is paramount, and collets are a key component in achieving that goal.

| Dimension | Feature | Function | Material Used |

|---|---|---|---|

| Size Range | Versatile and Adjustable | Securely holds different workpiece sizes | Aluminum, Steel, or Plastic |

| Taper Style | Precision Fit | Ensures minimal run-out | Steel or High-Speed Steel |

| Collet Type | Different Styles Available | Specialized gripping for various applications | Carbon Steel, Alloy Steel |

| Clamping Force | High Clamping Capability | Maintains workpiece stability | Stainless Steel, Tool Steel |

| Application | Used in Various Industries | Best for turning, drilling, and milling | Various Metals and Plastics |

Collet design plays a crucial role in achieving precision in machining. These tools securely hold workpieces, ensuring they remain stable during operations. A well-designed collet minimizes any chances of vibration. This stability leads to more accurate cuts. Precision is vital in many industries, from aerospace to medical device manufacturing.

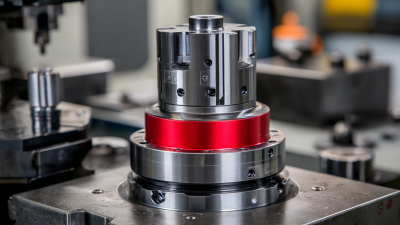

When considering collet design, compatibility with the lathe is key. An improper fit can cause issues like slipping or misalignment. Each collet's shape and size must match the specific requirements of the task. Unfortunately, many overlook this factor. Choosing the wrong collet can lead to significant errors in machining.

Durability is another aspect of collet design. High-quality materials reduce wear and tear. However, users sometimes forget to maintain their collets properly. Regular cleaning and inspection could prolong their life. A worn collet might compromise machining accuracy, leading to costly mistakes. The importance of thoughtful collet design and care cannot be overstated.

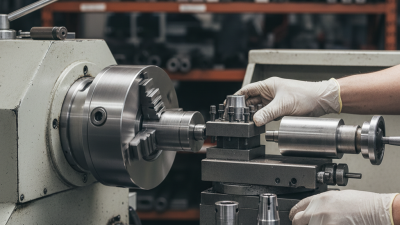

Collets are crucial in lathe work. They provide a secure grip on the workpiece, ensuring precision. Different types of collets serve various purposes. For instance, ER collets are widely used for their versatility in holding tools and materials.

Another type is the 5C collet, known for its strength. This collet type is commonly used in production settings. It can handle larger diameters, ideal for heavier tasks. However, achieving the right fit can be challenging. Misalignment can occur, impacting the quality of work.

Additionally, there are step collets and hex collets. Step collets allow for multiple diameter workpieces. They simplify setups and enhance efficiency. But they might not be suitable for all applications. Each choice demands careful consideration. Mistakes in selection can lead to inefficiencies.

Collets are increasingly popular in precision machining. They offer several benefits over traditional chuck systems. One major advantage is their ability to grip workpieces with higher precision. This results in reduced runout, meaning the tool can operate more accurately. Operators often notice significant improvements in the quality of their finished products.

Collets also provide ease of use. Changing a collet is often quicker than switching out a traditional chuck. This can save valuable time during production runs. Many machinists appreciate the ability to switch tools without complicated setups. However, collets might require more care and maintenance compared to chucks. They can wear out, leading to performance degradation.

Another point to consider is versatility. Collets can accommodate various sizes and shapes. This flexibility can be crucial for complex projects. Yet, many users sometimes struggle with the best collet choices for their specific needs. Learning to leverage collets effectively involves some trial and error. Thus, continuous improvement is essential for maximizing their potential in precision machining.

Collets play a critical role in precision machining. They secure workpieces firmly, ensuring accuracy during the lathe operation. For optimal performance, regular maintenance of collets is essential. One common mistake is neglecting cleaning. Built-up dirt can impact precision. A simple wipe-down after each use can go a long way.

Inspecting collets is another vital practice. Look for any signs of wear, cracks, or deformation. These issues can lead to poor gripping and inaccuracies. Replacing worn collets on time is often overlooked. It's easy to think, "I'll manage just one more job." However, this can result in costly errors.

Finally, proper storage is often ignored. Placing collets in a designated container keeps them safe. A chaotic workspace can lead to misplacements or accidental damage. Each step in maintaining collets contributes to their longevity. Skipping these practices can diminish performance over time. Working with precision requires attention to detail.