- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In today's competitive manufacturing landscape, businesses are constantly seeking innovative methods to enhance efficiency and productivity. One such transformative approach is Cnc Custom Machining, a technique that allows for precision and customization in the production process. This advanced machining technology not only streamlines operations but also provides manufacturers with the flexibility to create complex designs tailored to specific project requirements.

As industries evolve and demand for unique products increases, understanding how Cnc Custom Machining can significantly improve manufacturing processes becomes essential. In this blog, we will explore five key ways in which Cnc Custom Machining enhances your manufacturing capabilities, driving both quality and speed while reducing costs. Embrace the potential of this cutting-edge technology and redefine your manufacturing approach with bespoke solutions that meet the needs of a dynamic market.

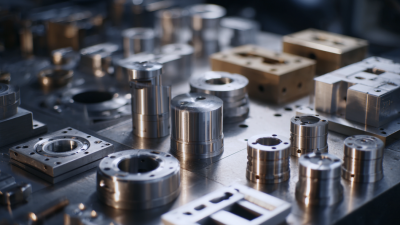

CNC machining has revolutionized the manufacturing process by enabling the production of intricate designs that were once deemed impossible. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100.2 billion by 2026, driven primarily by the demand for complex geometries across various sectors. This innovative technology utilizes computer programming to control machinery with precision, allowing manufacturers to design components with detailed features not achievable through traditional machining methods.

CNC machining has revolutionized the manufacturing process by enabling the production of intricate designs that were once deemed impossible. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100.2 billion by 2026, driven primarily by the demand for complex geometries across various sectors. This innovative technology utilizes computer programming to control machinery with precision, allowing manufacturers to design components with detailed features not achievable through traditional machining methods.

One of the key advantages of CNC machining in facilitating complex geometries lies in its ability to produce parts with high repeatability and accuracy. A report from Grand View Research highlights that companies leveraging CNC machining can achieve tolerances as tight as ±0.005 inches. This capability not only reduces waste but also enhances product performance, especially in industries such as aerospace, automotive, and medical devices where precision is paramount. With CNC technology, manufacturers can experiment with innovative designs, enabling the creation of lightweight yet robust components that meet stringent performance standards while minimizing material costs.

In the realm of modern manufacturing, precision engineering has become paramount, and CNC custom machining stands at the forefront of achieving exact tolerances. Recent industry reports indicate that manufacturers employing CNC machining can achieve tolerances as tight as ±0.01 mm, significantly enhancing the quality of their products. This level of precision not only minimizes waste and rework costs but also accelerates production timelines, allowing businesses to meet market demands more effectively.

Tip: When selecting a CNC machining service, ensure they utilize advanced software for simulations, as this can further refine the accuracy of the final product.

CNC custom machining employs computer-controlled tools that execute precise movements and adjustments, transforming raw materials into finished components with unparalleled accuracy. This technology plays a crucial role across various industries, from aerospace to medical devices, where even minor deviations can lead to catastrophic failures. A recent survey by an industry consortium highlighted that 75% of manufacturers view CNC machining as a critical component of their competitive strategy.

Tip: Regularly review and update your CNC machining process to incorporate the latest technological advancements, ensuring your manufacturing capabilities remain cutting-edge.

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Precision | CNC machining provides high levels of accuracy and repeatability. | Ensures components meet exact tolerances, reducing errors and rework. |

| Flexibility | CNC machines can be reprogrammed quickly for new designs. | Facilitates quick adaptations to changing market demands. |

| Efficiency | Automated processes reduce production time significantly. | Increases output while minimizing labor costs and time. |

| Material Utilization | CNC machining maximizes material use, resulting in less waste. | Reduces costs associated with material procurement and disposal. |

| Complex Geometries | CNC enables manufacturing of intricate and complex parts. | Empowers innovation in product design, enhancing competitive advantage. |

CNC custom machining has revolutionized the manufacturing landscape, particularly in enhancing material efficiency. According to a report from the National Institute of Standards and Technology (NIST), the manufacturing industry annually wastes about 20-30% of the raw materials used, translating into significant financial losses. CNC machining significantly reduces this waste by utilizing precise cutting and shaping techniques. Unlike traditional machining methods, which often result in considerable leftover material, CNC techniques maximize raw material use, ensuring optimal production resources.

Tips: To enhance material efficiency in your operations, consider investing in advanced CNC machinery equipped with real-time monitoring systems. These systems can analyze production data, allowing for better material utilization and identifying waste sources. Additionally, integrating software that simulates machining processes can help in planning and optimizing cuts before actual production begins.

Furthermore, CNC machining fosters the use of recyclable materials, aligning with industry trends towards sustainability. Reports by the World Economic Forum indicate that circular manufacturing models can reduce waste by 70% or more over traditional practices. By adopting CNC processes, manufacturers not only improve their bottom line but also contribute positively to environmental sustainability efforts.

Tips: Regularly review your machining strategies and involve your team in identifying areas for improvement. Engaging all stakeholders in the efficiency conversation can lead to innovative methods and optimize your CNC operations continuously.

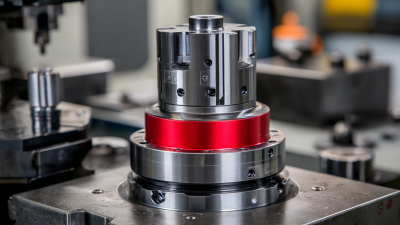

The rapid prototyping landscape is witnessing a significant transformation, particularly through the advancements in CNC custom machining techniques. By allowing for precise and efficient prototype development, CNC machining accelerates the entire product development lifecycle. Manufacturers can swiftly translate their ideas into tangible products, enabling them to test functionality and design much earlier in the process. This efficiency not only shortens lead times but also optimizes resource allocation, ensuring that businesses remain competitive in a fast-paced market.

As the global market for rapid prototyping materials is projected to soar from $746.7 million in 2024 to $2.827 billion by 2032, achieving a remarkable compound annual growth rate of 18.1%, the advantages of CNC custom machining become even clearer. This growth is largely fueled by the increasing demand for customized components and the need for rapid iteration in product design. Companies leveraging CNC machining can create high-quality prototypes with intricate designs, which can be adjusted easily based on feedback, further driving innovation and efficiency in manufacturing processes.

CNC custom machining offers significant economic benefits that can enhance the overall manufacturing process. By automating precision machining, companies reduce the dependence on manual labor, leading to lower labor costs. The efficiency of CNC machines minimizes the time required for production, allowing manufacturers to meet tight deadlines without sacrificing quality. This time-saving aspect contributes to an increase in throughput, directly affecting the bottom line by enabling higher production volumes at a lower cost per unit.

Another crucial economic advantage of CNC machining is its ability to reduce material waste. Traditional machining methods often result in excessive scrap and inefficient use of raw materials. CNC machines, with their precise cutting capabilities, optimize material usage, ensuring that every part produced is usable. This not only lowers material costs but also promotes more sustainable manufacturing practices. Moreover, the capacity for customization with CNC technology means that manufacturers can cater to specific client needs without incurring additional costs associated with tooling changes or reworks, making it a potent tool in enhancing profitability and competitive advantage in the market.