- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

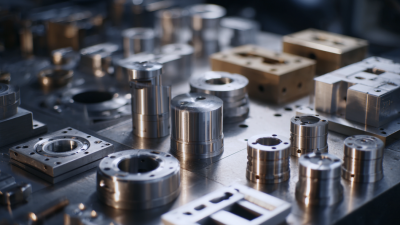

In the realm of precision machining, selecting the appropriate tooling can significantly impact the efficiency and quality of lathe operations. A crucial component in this process is the collet, which plays a pivotal role in effectively securing workpieces and enhancing operational accuracy. Research indicates that the global collet market is projected to reach $2.17 billion by 2026, growing at a CAGR of 6.3% from 2021, underscoring the increasing reliance on specialized collet systems. The right collet for lathe not only improves gripping force but also reduces cycle times and fatigue on the spindle, promoting sustainability in manufacturing practices. As such, understanding the various types of collets available and their specific applications can lead to optimized lathe performance and superior end results in machining applications.

When it comes to lathe operations, choosing the right collet can significantly impact your machining efficiency and precision. Understanding the different types of collets is essential for attaining optimal performance. The most common types are the ER collets, which are known for their versatility and ability to hold various tool sizes. Their design allows for a wide range of clamping diameters, making them ideal for both small and large milling tasks.

Another popular option is the 5C collet, especially favored in tool and die shops. These collets provide a strong grip and are primarily used with precision machining because of their tighter tolerances. They can hold round, square, and hexagonal parts, which makes them an excellent choice for a diverse range of applications. Choosing the right collet type depends on your specific machining needs, including the material you're working with and the precision required for your project. By understanding these essential options, you can enhance the effectiveness of your lathe operations.

When selecting the right collet for lathe operations, understanding the impact of diameter on precision and stability is crucial. The collet size directly influences the grip on the workpiece, and a poorly chosen diameter can lead to significant inaccuracies during machining. A larger collet may provide a loose hold, resulting in vibrations that can mar the finish, while a smaller collet can exert excessive pressure, potentially damaging both the collet and the workpiece itself.

Additionally, different materials and types of workpieces require specific collet diameters to maintain optimal stability. For instance, lightweight materials may necessitate a more precisely sized collet to prevent movement, whereas heavier components might benefit from a larger diameter that distributes forces more evenly. It's essential to assess the material characteristics and the intended lathe operation to make an informed choice, ensuring that the collet not only fits the workpiece but also enhances overall machining performance.

When it comes to lathe operations, choosing the right collet material is crucial for ensuring durability and precision in machining tasks. Different materials provide unique advantages, and understanding these can significantly impact your workflow. For instance, steel collets are renowned for their strength and resistance to wear, making them ideal for heavy-duty applications and high-torque requirements. On the other hand, aluminum collets are lighter and often preferred for their ease of use in lighter machining tasks, providing a balance between durability and agility.

Furthermore, the choice of collet material extends to applications involving varying degrees of accuracy and surface finishes. For operations that demand tight tolerances and minimal runout, materials such as high-grade steel or specialized alloys are exceptional choices due to their stability and resilience under pressure. Additionally, consider the environmental factors your collets will face, such as exposure to corrosive materials or extreme temperatures, as these can influence your selection. Ultimately, taking the time to select the appropriate collet material not only enhances tool longevity but also promotes better performance across your lathe operations.

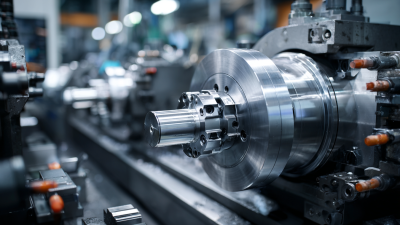

When selecting a collet for lathe operations, understanding the impact of clamping force on workpiece integrity and quality is crucial. Collets are designed to securely hold the workpiece in place, and the clamping force exerted by the collet can significantly affect surface finish and dimensional accuracy. Insufficient clamping force may lead to chatter or vibration, compromising the integrity of the machined surface and resulting in subpar quality, particularly when working with challenging materials like titanium alloys and nickel-based superalloys. The recent advances in research highlight the importance of controlling clamping systems to meet the demands of these sophisticated materials, ensuring that the processes do not adversely affect their surface integrity.

Moreover, developments in clamping systems that predict and reduce part distortion during machining are becoming increasingly valuable. As the industry pushes for higher precision and improved quality, understanding the interplay of clamping force and the machining process is essential. Similar to how different machining trajectory directions influence the grinding of titanium alloys, the variability in collet clamping methods can affect how heat-resistant high-alloy steels react during milling. By tailoring clamping solutions to match the specific requirements of the workpiece material, manufacturers can enhance overall quality and performance, ensuring that every component meets demanding standards.

When it comes to maximizing the performance of your lathe operations, proper maintenance of your collet system is crucial. Regular inspections should be a priority; check for any signs of wear or damage on the collet and spindle. Clean the collets after each use to remove any chips, dust, or lubricant residue that could impede their function. A simple brush or compressed air can effectively clear out debris, helping to maintain their precision and grip.

Lubrication is another key factor in ensuring the longevity of your collet system. Applying the right type of lubricant to the spindle and tightening mechanisms can help reduce friction and prevent wear. However, it is important to use lubricants that are compatible with your collet materials to avoid degradation. Additionally, routinely calibrating your collet system ensures that it fits securely and operates at optimal levels, preventing any unwanted slip during machining processes. By adhering to these maintenance tips, you can enhance the efficiency and lifespan of your collet system, leading to better overall performance in your lathe operations.

| Collet Type | Suitable Material | Max Load Capacity (lbs) | Best Usage | Maintenance Tips |

|---|---|---|---|---|

| ER Collet | Steel, Aluminum | 300 | Precision machining | Clean regularly, check for wear |

| Hex Collet | Steel, Brass | 250 | Milling operations | Oil lightly, inspect for damage |

| Pull Stud Collet | Aluminum, Titanium | 400 | Heavy-duty applications | Regularly tight, check fitment |

| Spring Collet | Copper, Plastics | 150 | General purpose | Store in a dry place, avoid twisting |