- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

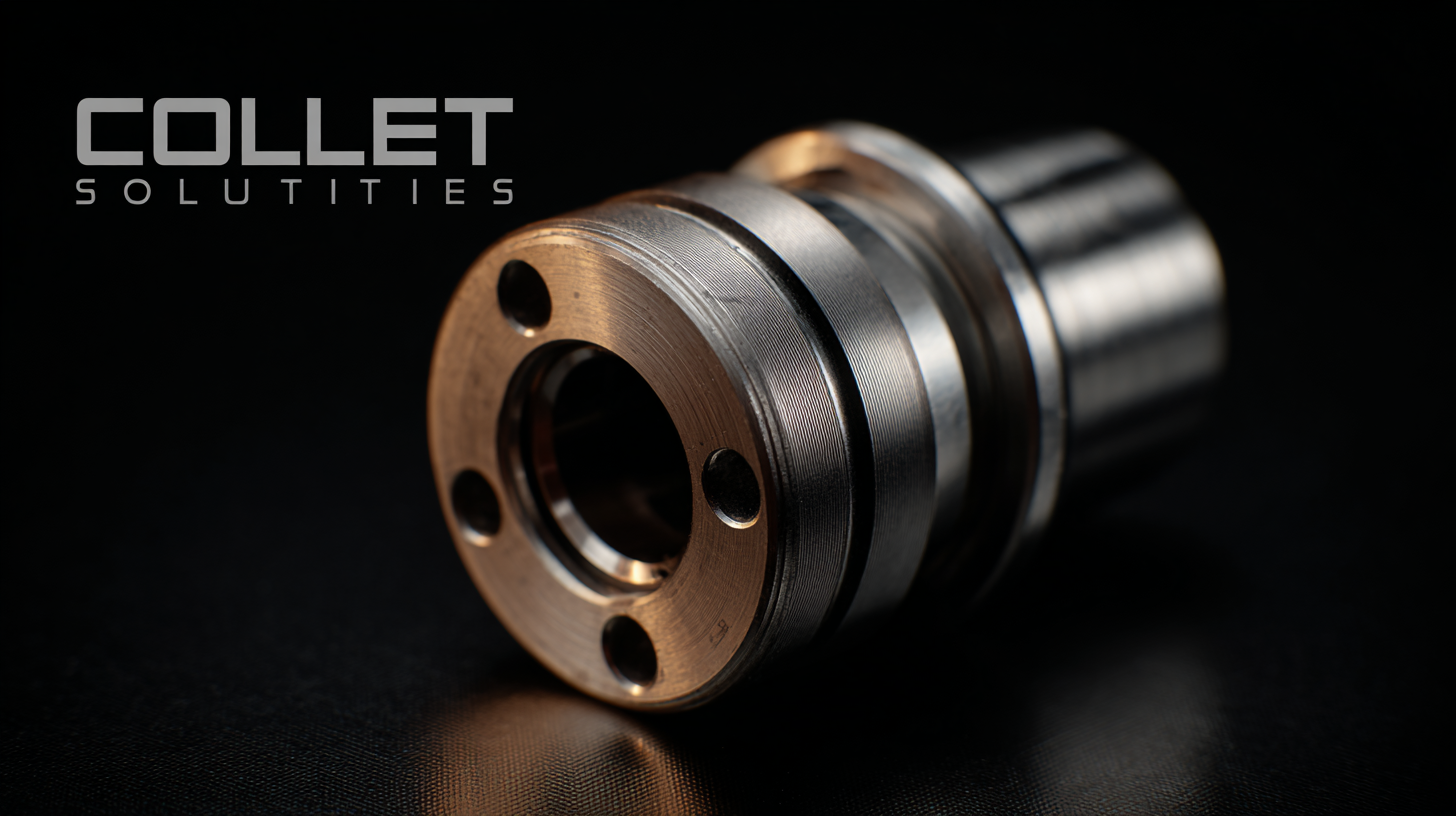

In the rapidly evolving landscape of manufacturing technology, selecting the right tools for precision and efficiency is paramount. As we look towards 2025, a notable trend is the increasing reliance on advanced collet systems to enhance lathe operations. According to a recent industry report by MarketsandMarkets, the global machine tool market is projected to reach $119.2 billion by 2025, driven by rising automation and the demand for high-quality machining processes. Among these tools, the collet for lathe stands out due to its ability to provide superior grip, accuracy, and versatility, making it essential for both small-scale workshops and large production facilities. With numerous options available, understanding how to choose the best collet for lathe applications will be crucial for manufacturers aiming to stay competitive and optimize their operations.

When selecting the right collet type for lathe applications, it's crucial to consider both the material and the collet design to ensure optimal performance. According to a report by the International Journal of Machine Tools and Manufacture, utilizing the correct collet type can improve gripping precision by up to 30%, significantly reducing workpiece deformation during machining processes. This precision is essential for industries where tolerances are tight, such as aerospace and automotive manufacturing.

Another key consideration is the collet size and type, which can vary based on the lathe's specifications and the workpieces being used. Standard options include ER collets, which are renowned for their versatility and gripping strength. A study published in the Journal of Manufacturing Science and Engineering highlighted that ER collets are capable of handling a range of diameters with minimal runout, making them suitable for both large and small parts. Furthermore, specialty collets, such as those designed for high-speed applications, can enhance productivity by enabling faster setup times and reduced tool change frequency. Understanding these elements will help machinists make informed choices that align with their operational needs.

When selecting the ideal collet for lathe operations, understanding the relationship between collet design, precision, and workpiece stability is paramount. According to a report by the American Society of Mechanical Engineers (ASME), the accuracy of a lathe's operations can vary by up to 15% depending on the quality and design of the collet used. For example, precision collets, such as Dawbarn or Hardinge designs, provide better centering characteristics which enhance workpiece stability during machining. This is crucial when handling high-tolerance components where any deviation can lead to significant production errors.

Moreover, the material composition of the collet plays a critical role in its performance. A study by the International Journal of Advanced Manufacturing Technology noted that hardened steel collets can maintain their rigidity under high rotational speeds, thus reducing vibration and improving overall machining outcomes. Vibrational stability is further enhanced when using collets that incorporate innovative grip designs, which can increase surface contact with the workpiece by approximately 20%, minimizing slippage and maximizing precision. Ultimately, by analyzing these factors, machinists can make informed choices that significantly impact their operational efficiency and the quality of their crafted parts.

| Collet Type | Max Diameter (mm) | Precision (μm) | Stability Rating | Material |

|---|---|---|---|---|

| A-Type Collet | 25 | 5 | High | Steel |

| B-Type Collet | 30 | 7 | Medium | Aluminum |

| C-Type Collet | 20 | 3 | Very High | Titanium |

| D-Type Collet | 40 | 6 | High | Carbon Steel |

When selecting the right collet for your lathe, the material choice significantly impacts performance. Steel and aluminum are the two predominant materials, each offering distinct advantages. Steel collets are renowned for their durability and strength, making them ideal for high-precision applications where minimal tool deflection is crucial. They withstand high torque and can handle heavier workloads without deforming, ensuring a consistent and reliable grip on the workpiece.

On the other hand, aluminum collets present a lighter alternative, which can contribute to faster spindle speeds and reduced vibration during machining. Their lower weight allows for quicker acceleration, making them suitable for applications where speed is essential. Aluminum also has a natural resistance to corrosion, which can be beneficial in various working environments. However, they may not provide the same level of rigidity as steel collets, often making them a better choice for lighter parts or in situations where precision is less critical.

Ultimately, the decision between steel and aluminum collets should be guided by the specific lathe requirements and the nature of the work being performed.

When selecting a collet for your lathe needs, it's crucial to consider both the capacity and compatibility with your specific lathe model. Collet capacity refers to the range of sizes it can securely hold, which ultimately impacts the versatility of your lathe operations. Ensure that you match the collet’s capacity with the types of workpieces you plan to use. For instance, if you're often handling larger stock materials, opting for a collet with a higher capacity not only provides flexibility but also enhances precision.

Tip: Always check the specifications of your lathe model to ensure the collet you choose fits perfectly. This includes considering the collet's taper and thread size, as mismatches can lead to operational inefficiencies and potential damage.

Another important aspect is compatibility with various lathe models. Different lathes may require specific types of collets, such as ER or 5C. Understanding your lathe's design will prevent any future inconveniences. Additionally, invest in collet systems that offer adapters, allowing for easy switching between different sizes and styles without the need for multiple setups.

Tip: Consult your lathe's user manual or manufacturer guidelines to identify recommended collet types, as this can save you time and enhance your machining processes.

Proper maintenance and care of your lathe collets are crucial for ensuring their longevity and performance. Regular cleaning is fundamental; accumulated debris and fine metal particles can affect the precision and functionality of the collet. After each use, make it a habit to wipe down the collet with a soft cloth and a suitable solvent to remove any contaminants. Additionally, inspect for any signs of wear or damage regularly. Persistent wear can lead to inaccuracies in machined parts, so identifying issues early can save time and reduce costs.

Lubrication also plays a vital role in extending the lifespan of lathe collets. Using the right lubricant minimizes friction and helps maintain a smooth operation. Ensure that the lubrication is compatible with the materials of the collet and the lathe. Furthermore, store collets in a clean, dry environment to prevent rust and corrosion. Using protective cases or shelves helps safeguard them from accidental damage. By implementing these best practices, you can maintain your lathe collets in optimal condition, ensuring consistent accuracy in your machining projects.