- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

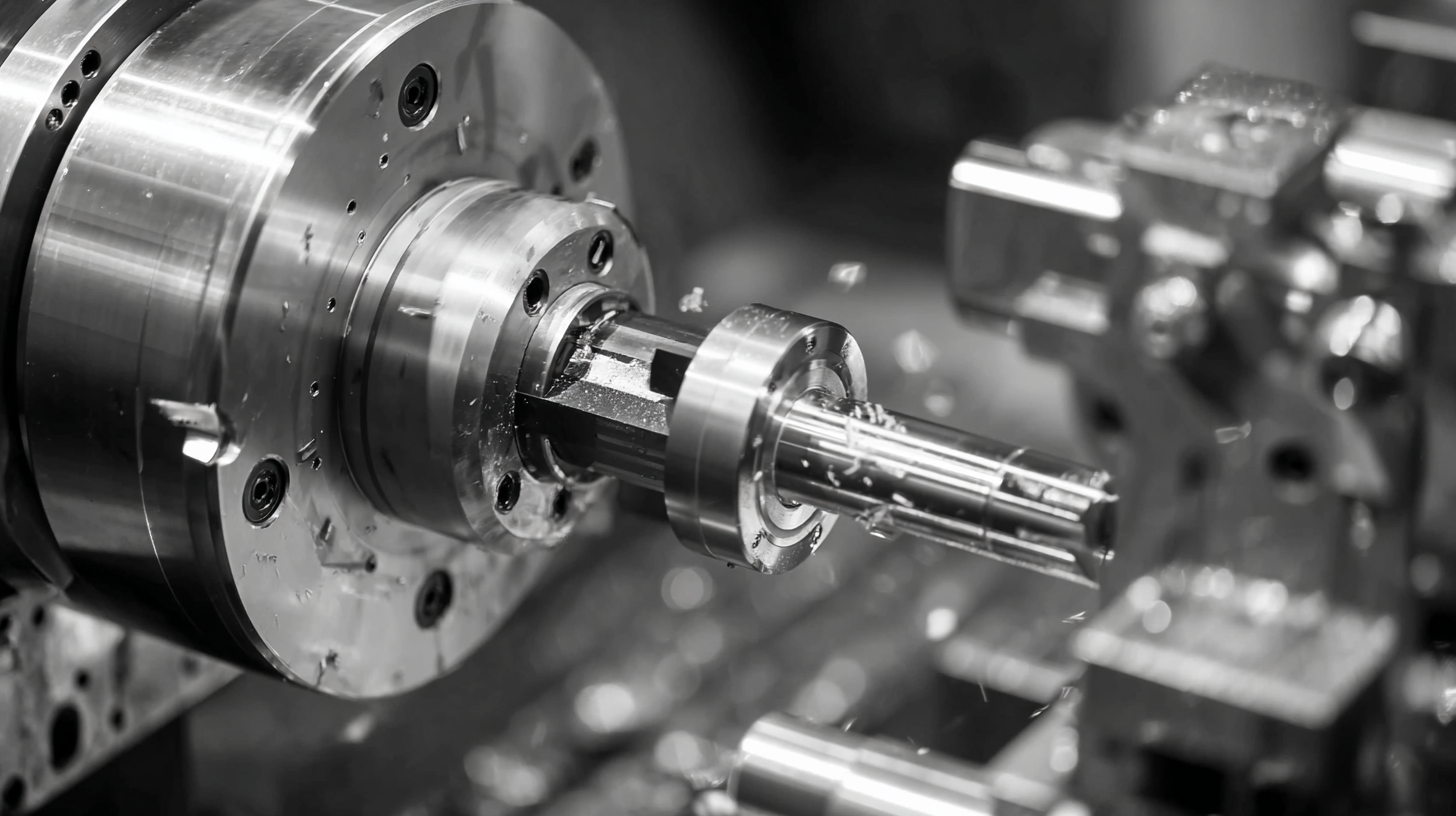

In today's competitive manufacturing landscape, choosing the right CNC custom machining services is crucial for businesses looking to maintain efficiency and quality. According to a recent report by Grand View Research, the global CNC machining market is projected to reach USD 100.5 billion by 2025, growing at a CAGR of 6.5%. This growth underscores the increasing reliance on CNC custom machining as a means to produce precise components across various industries, including aerospace, automotive, and medical devices. With technological advancements and the demand for high-quality, customized parts on the rise, selecting the best CNC custom machining provider can significantly impact your operations. This blog will explore key factors to consider, ensuring your business leverages cutting-edge CNC solutions effectively and efficiently.

When selecting the best CNC custom machining services for your business, it's crucial to clearly understand your project requirements. Start by evaluating the specific materials and tolerances needed for your project, as this will influence the type of CNC machinery you should consider. Recent advancements in CNC technology have significantly improved production speeds, with some new machinery offering up to a 20% increase in efficiency. Therefore, selecting a service provider with state-of-the-art equipment can lead to faster turnarounds and improved overall reliability.

**Tips:**

- Identify the complexity of your design and the materials involved; this will guide you in choosing the right CNC services.

- Look for service providers that offer a range of options, such as CNC machining, 3D printing, and laser cutting, to meet all your manufacturing needs.

- Consider leveraging multi-criteria decision-making strategies to ensure that you select a service that aligns with your project goals, budget, and timeline.

Understanding these aspects will empower you to make informed decisions that align with your business objectives while also taking advantage of the latest developments in the CNC machining industry.

| Criteria | Description | Importance (1-5) | Examples |

|---|---|---|---|

| Material Capability | Types of materials that can be machined (e.g., metals, plastics). | 5 | Aluminum, Steel, PVC |

| Precision | The accuracy of the machining process. | 5 | Tolerance levels of ±0.001 inches |

| Experience | Years in business and expertise in specific industries. | 4 | Automotive, Aerospace, Medical |

| Turnaround Time | Time taken to complete the machining project. | 4 | Standard: 2-4 weeks |

| Cost | Pricing structure and overall cost of services. | 3 | Price per hour or per part |

| Customer Support | Quality of communication and support during the project. | 5 | Responsive before and after machining |

When selecting CNC custom machining services, it's crucial to evaluate the capabilities and expertise of potential partners. Begin by assessing their technology and equipment. Advanced CNC machines can produce complex parts with precision, so ensure that the service provider is equipped with modern machinery suitable for your specific requirements. Additionally, inquire about their software capabilities, as cutting-edge CAD/CAM systems can enhance the design and manufacturing processes, resulting in better-quality products.

Another key aspect to consider is the experience and expertise of the machining team. A skilled workforce is essential for maintaining quality and efficiency in production. Look for companies that have a proven track record in your industry, and pay attention to their certifications and training programs. Engaging with their existing clients for testimonials or case studies can provide deeper insights into their ability to handle projects similar to yours. This thorough evaluation will enable you to choose a CNC machining service that not only meets your business needs but also contributes to the long-term success of your projects.

When selecting CNC custom machining services for your business, assessing material options is crucial. The choice of material can significantly impact not only the production process but also the final product's quality, durability, and cost-effectiveness. Different materials come with unique properties; for instance, aluminum is lightweight and offers excellent machinability, making it a popular choice for various applications. In contrast, stainless steel provides superior corrosion resistance, essential for parts exposed to harsh environments. Therefore, understanding your project's specific requirements will guide you in choosing the right material that aligns with both functionality and budget.

Additionally, the compatibility of materials with machining techniques plays a vital role in the efficiency of the production process. Some materials require specialized tools or machining settings that can affect turnaround times and overall costs. For businesses that prioritize precision and speed, it's imperative to collaborate with CNC service providers who have experience working with your chosen materials. By communicating your material preferences upfront, you can ensure they have the necessary capabilities and expertise to handle your project, ultimately leading to optimized production outcomes.

When selecting CNC custom machining services, understanding the cost structures involved is crucial for maximizing value. According to a report from IBISWorld, the CNC machining industry in the United States generates over $20 billion annually, with average profit margins around 15%. These figures emphasize the importance of analyzing providers not just based on their quotes, but also on the value they deliver. For instance, if one service offers lower prices but lacks quality controls, the eventual costs of rework and delays can significantly outweigh the initial savings.

Tip: Always request detailed quotes that break down costs into labor, materials, and overhead to better understand what you’re paying for.

Value isn’t solely determined by cost; it often hinges on quality, delivery times, and customer support. The 2023 CNC Machining Industry Report indicates that businesses choosing high-quality providers typically experience 30% lower defect rates. Therefore, investing a bit more for superior craftsmanship can lead to long-term savings.

Tip: Seek out reviews and case studies from potential machining partners to gauge their reliability and service history before making a decision.

When choosing CNC custom machining services for your business, customer feedback is an invaluable resource. Reviews and ratings provide insights into the reliability and quality of a service provider. Look for patterns in customer experiences; consistent praise for precision and timeliness can indicate a trustworthy company. Check reputable platforms and forums where users share their recommendations, and don't hesitate to engage in discussions or ask for personal experiences from fellow business owners.

In addition to understanding the general sentiment through feedback, pay attention to the specifics. Evaluate comments regarding a company's responsiveness to inquiries, their ability to meet deadlines, and how they handle issues or revisions. These factors are crucial in ensuring smooth communication and collaboration throughout the machining process. Customer recommendations often highlight not just the technical skills of a machinist, but also their professionalism and customer service, which can significantly impact your project’s success. Use this feedback as a guide to select a machining service that aligns with your business needs and values.