- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the competitive landscape of manufacturing, collet manufacturers face a myriad of challenges that can impede production efficiency and overall operational effectiveness. As precision components essential for holding and gripping tools, collets require meticulous design and fabrication processes, making it crucial for manufacturers to continually refine their methodologies. This blog aims to address the common hurdles encountered by collet manufacturers, focusing on the importance of optimizing production lines, managing material costs, and enhancing quality control measures. By highlighting the comparison between traditional methods and innovative practices, we will explore how embracing new technologies and strategies can significantly improve operational performance, enabling collet manufacturers to thrive in an ever-evolving market. Through this discussion, we hope to provide valuable insights that can lead to tangible improvements in production efficiency for collet manufacturers.

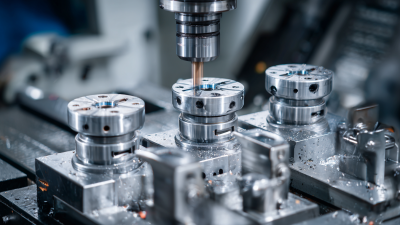

In the competitive landscape of collet manufacturing, identifying key production inefficiencies is crucial for enhancing overall productivity. One significant challenge is the lack of standardized processes across different production lines. Variability in machining techniques, tool wear, and operator experience can lead to inconsistencies in product quality and increased waste. Standardizing operations not only improves consistency but also streamlines training for new employees, thereby minimizing downtime and enhancing skill levels across the workforce.

Another critical inefficiency stems from inadequate predictive maintenance practices. Many manufacturers rely on reactive maintenance schedules, which often result in unexpected machine failures and prolonged downtime. By implementing a proactive maintenance strategy, manufacturers can monitor equipment health in real time, anticipate potential breakdowns, and schedule maintenance activities during non-productive hours. This approach not only reduces unplanned outages but also extends the lifespan of machinery, ultimately contributing to smoother operations and improved production efficiency.

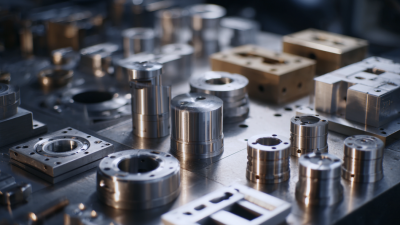

The collet manufacturing sector faces significant challenges in optimizing production efficiency, particularly when it comes to enhancing the durability and performance of collets. One effective approach to address these challenges is the utilization of advanced materials. According to a recent market report by Grand View Research, the global advanced materials market is projected to reach $124 billion by 2025, driven by the increasing demand for high-performance materials in various industries, including manufacturing. By integrating advanced materials such as titanium alloys and composites, collet manufacturers can significantly improve both the lifespan and functionality of their products.

Advanced materials not only contribute to enhanced durability but also optimize performance under high-stress conditions. Research published in the Journal of Materials Science indicates that titanium-based collets exhibit a remarkable increase in load-bearing capacity and resistance to wear. This is particularly crucial in precision engineering applications, where even minute failures can lead to costly downtimes. Moreover, the lightweight nature of these advanced materials allows for more efficient designs, resulting in reduced energy consumption during production processes. As manufacturers leverage these innovative materials, the potential for significant improvements in production efficiency and overall product quality becomes increasingly achievable.

This chart illustrates the production efficiency of collet manufacturers over the last five years, highlighting the impact of using advanced materials on durability and performance.

In the competitive landscape of collet manufacturing, implementing lean manufacturing techniques has become crucial for enhancing production efficiency. According to a report from the Lean Enterprise Institute, companies that adopt lean practices can improve their operational efficiency by up to 30% while decreasing production costs by 20%. For collet manufacturers, this means streamlining processes such as material handling, machining, and assembly, which are often hindered by excessive inventory and inefficient workflows.

By focusing on value-stream mapping, collet manufacturers can identify and eliminate waste in their production lines. For instance, standardized work procedures have been shown to reduce cycle times by as much as 25%, allowing manufacturers to increase their throughput without compromising quality. Furthermore, introducing just-in-time (JIT) inventory systems can minimize storage costs and lead time, fostering a more responsive manufacturing environment. As the collet industry continues to evolve, those who embrace lean principles will not only enhance their production capabilities but also position themselves favorably against competitors.

| Challenge | Description | Lean Manufacturing Technique | Expected Outcome |

|---|---|---|---|

| Inventory Management | Excessive raw materials and work-in-progress inventory. | Just-In-Time (JIT) Inventory | Reduced holding costs and improved cash flow. |

| Production Delays | Unpredictable production schedules leading to delays. | Value Stream Mapping | Streamlined processes and reduced lead times. |

| Quality Control | Inconsistent product quality leading to rework. | Continuous Improvement (Kaizen) | Enhanced product quality with fewer defects. |

| Employee Training | Skills gap among workers resulting in inefficiencies. | Standardized Work Procedures | Increased worker efficiency and reduced errors. |

| Equipment Downtime | Frequent breakdowns causing lost production time. | Total Productive Maintenance (TPM) | Improved machine reliability and production output. |

In the competitive landscape of collet manufacturing, automation technologies are increasingly becoming a pivotal solution for enhancing production efficiency. According to a report by MarketsandMarkets, the global industrial automation market is projected to grow from $175 billion in 2020 to over $300 billion by 2026, highlighting a significant shift towards automated solutions in various manufacturing sectors. Manufacturers embracing automation can expect a reduction in cycle times, leading to improved throughput and ultimately, increased profitability.

Additionally, the integration of advanced robotics and artificial intelligence into collet production lines is transforming operational capabilities. A survey conducted by McKinsey & Company indicates that companies leveraging automation technologies have experienced a productivity increase of up to 30%. These advancements also contribute to improved precision and consistency in manufacturing processes, which is crucial in producing high-quality collets designed for precision applications. With machinery that can operate 24/7 with minimal human intervention, manufacturers not only streamline their operations but also better meet the growing demand for faster and more reliable products in the market.

In the competitive landscape of collet manufacturing, maintaining production efficiency while ensuring high-quality output is paramount. A critical aspect of this balance lies in the implementation of robust quality control metrics aimed at minimizing defects during the manufacturing process. According to a recent report by the International Journal of Advanced Manufacturing Technology, defective parts can lead to operational inefficiencies costing manufacturers up to 15% of their overall revenue. By focusing on precise measurement systems, manufacturers can identify faults at an early stage, reducing waste and enhancing product quality.

One effective quality control metric involves the use of Statistical Process Control (SPC), which allows manufacturers to monitor production processes continuously. Implementing SPC can lower defect rates by as much as 30%, as noted in a study by the Society of Manufacturing Engineers. Additionally, regular audits and feedback loops are essential for sustaining quality standards. Establishing clear benchmarks based on industry standards ensures that manufacturers can not only track their performance but also make informed adjustments to improve production workflows. Emphasizing quality control not only aids in reducing defect rates but also boosts customer satisfaction, creating a ripple effect that can enhance market position.