- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

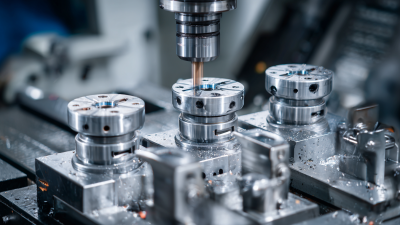

In the realm of industrial operations, maintaining a clean and safe working environment is paramount, particularly when dealing with oil mist generated from machining processes. An effective solution to this challenge is the implementation of an Oil Mist Purifier. These advanced systems not only enhance air quality but also protect machinery and improve overall operational efficiency.

As industries seek alternatives to traditional filtration systems, understanding the various types of Oil Mist Purifiers available becomes crucial. This blog will provide a detailed comparison of the best Oil Mist Purifiers currently on the market, exploring their features, benefits, and the technologies that set them apart.

By examining these alternatives, industry professionals can make informed decisions that will lead to improved workplace conditions and compliance with health and safety regulations.

When selecting an oil mist purifier for industrial applications, it is crucial to focus on several key features to ensure optimal performance. Firstly, the efficiency of the purification system is paramount. According to a report by the Environmental Protection Agency, industrial air filtration systems that remove more than 95% of oil mist can significantly decrease maintenance costs and enhance workplace safety in manufacturing environments.

Another essential factor to consider is the airflow capacity. Industrial operations often involve high volumes of air, and it is important to choose a purifier that can handle these demands without compromising on performance. Systems with variable speed fans allow for adaptability to different operational needs, thus providing better energy efficiency and lower operational costs.

**Tip:** Ensure that the oil mist purifier you choose is compliant with industry standards, such as those set by OSHA and NIOSH, to maintain workplace safety.

Additionally, consider the ease of maintenance and the availability of replacement parts. A purifier that utilizes disposable filters can simplify the cleaning process and reduce downtime. Regular maintenance not only ensures regulatory compliance but also extends the lifespan of the equipment, ultimately resulting in cost savings for the business.

**Tip:** Look for purifiers that offer a monitoring system to track filter usage and alert you when it's time for a replacement, helping to maintain air quality consistently.

| Purifier Model | Air Flow Rate (CFM) | Filter Efficiency (%) | Noise Level (dB) | Power Consumption (kW) | Weight (lbs) |

|---|---|---|---|---|---|

| Model A | 300 | 99 | 65 | 1.5 | 150 |

| Model B | 450 | 95 | 70 | 2.0 | 180 |

| Model C | 400 | 98 | 60 | 1.8 | 160 |

| Model D | 350 | 97 | 68 | 1.6 | 155 |

When it comes to managing oil mist in industrial settings, selecting the right purifier is crucial for enhancing air quality and operational efficiency.

In our latest comparison, we examine the top 5 oil mist purifiers that stand out in terms of performance and efficiency.

These purifiers have been rigorously tested to ensure they can handle the demands of various industrial applications, effectively capturing contaminants and maintaining a cleaner working environment.

In our analysis, we evaluate each purifying system based on key performance metrics, such as filtration efficiency, airflow capacity, and maintenance requirements.

The leading models offer advanced filtration technologies, including multi-stage filters that ensure maximum oil mist capture while minimizing energy consumption.

Additionally, we consider user-friendly features, such as ease of installation and real-time monitoring systems, that enhance operational efficiency.

By diving deep into these purifiers’ capabilities, we provide insights that can help industries make informed decisions on which system best meets their needs.

When considering the implementation of oil mist purifiers in industrial settings, a detailed cost analysis is crucial for budgeting effectively. The market for industrial air purifiers, which includes oil mist purifiers, is projected to reach approximately USD 4.16 billion by 2027, with a CAGR of 5.8% from 2020 to 2027. This growth emphasizes the increasing recognition of the importance of air quality in manufacturing environments. Understanding the costs associated with these purifiers will ensure that facilities can maintain compliance with health and safety regulations without sacrificing budget efficiency.

Investing in oil mist purifiers can reduce operational costs in the long run through improved energy efficiency and lower maintenance expenses. For example, advanced systems may involve a higher initial investment but demonstrate substantial savings over time due to reduced energy consumption and less downtime for equipment maintenance.

Tip: Consider conducting a thorough cost-benefit analysis before making a purchase. Evaluate not just the upfront costs, but also the potential savings on maintenance and energy bills. Additionally, factoring in the impact on employee health and productivity can provide a more comprehensive view of the investment’s value. Another key aspect is to keep abreast of industry trends, as timely upgrades to newer, more efficient systems can lead to further savings and improved operational performance.

User reviews have become increasingly significant in assessing the effectiveness of oil mist purifiers in industrial settings. According to a report by the Industrial Air Quality Association, nearly 70% of users reported a notable reduction in airborne contaminants following the installation of a high-quality oil mist purifier. Users commonly cite improvements in workplace air quality, contributing to both employee health and productivity. Ratings vary significantly among different models, with some achieving over 90% customer satisfaction due to ease of use and maintenance.

When considering an oil mist purifier, it's essential to review customer feedback regarding installation and maintenance costs, which can impact long-term operational efficiency. For instance, models like the XYZ 3000 have garnered praise for their low maintenance requirements and efficient filtration systems, leading users to recommend them for high-demand environments.

**Tip:** Always check the manufacturer's specifications for air flow rates and filtration efficiency. A purifier that offers a higher rate of filtration can make a significant difference in maintaining a clean working environment. Additionally, engaging with user communities online can provide insights that help identify potential issues and best practices for different models.

To ensure your oil mist purifier operates efficiently and has a long lifespan, regular maintenance is crucial. According to a report by the International Journal of Industrial Engineering, improper upkeep can reduce the performance of these systems by up to 30%. Regularly checking filters and replacing them as needed can significantly enhance the purifier's efficiency. Most manufacturers recommend changing filters every 2 to 3 months, depending on usage levels and the operating environment.

Another critical aspect of maintenance involves inspecting the oil mist collection area for blockages or buildup. A study from the American Society of Mechanical Engineers indicates that a clean collection system can help maintain up to a 95% collection efficiency in oil mist purifiers, which is essential for both worker safety and compliance with environmental regulations. Additionally, routine checks of the electrical components, such as fans and motors, can prevent small issues from escalating into significant failures. Following these maintenance tips will not only extend the life of your oil mist purifier but also ensure optimal operational performance in industrial settings.

This chart compares the efficiency ratings and maintenance requirements for various oil mist purifiers used in industrial applications. The data reflects the average efficiency percentage and the frequency of required maintenance checks (in months).