- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

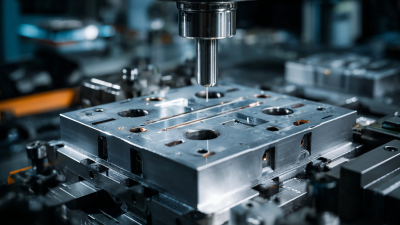

In today's industrial landscape, the importance of maintaining a clean and safe working environment cannot be overstated. Oil mist generated during machining and manufacturing processes not only poses serious health risks to workers but also contributes to significant equipment wear and operational inefficiencies. According to the National Institute for Occupational Safety and Health (NIOSH), exposure to oil mist can lead to respiratory issues and long-term health problems for employees, making the implementation of effective filtration systems critical. One such solution gaining recognition in various industries is the Oil Mist Purifier.

Dr. Emily Lawson, a leading expert in industrial air quality and senior researcher at the Institute of Clean Technologies, emphasizes the necessity of these systems: "The integration of an Oil Mist Purifier is not just about compliance; it's about proactively safeguarding the workforce and enhancing production efficiency." Her insights underscore the transformative impact that an Oil Mist Purifier can have, as these systems efficiently filter and eliminate oil mist from the air, contributing to a healthier workplace environment. In fact, a recent industry report revealed that businesses utilizing oil mist purification technology have experienced a 25% reduction in machine downtime and a significant decrease in maintenance costs, illustrating the dual benefits of health safety and operational excellence. As industries continue to evolve, adopting innovative solutions like the Oil Mist Purifier will be paramount in promoting sustainability and worker well-being.

Oil mist purifiers play a crucial role in maintaining a safe and clean working environment in various industrial settings. These devices are specifically designed to capture and filter airborne oil mist generated from machining processes, ensuring that air quality is preserved. According to a report from the National Institute for Occupational Safety and Health (NIOSH), exposure to oil mist can lead to significant respiratory issues, skin diseases, and other health problems for workers. Thus, the implementation of effective oil mist purification systems is not only a compliance measure but also fundamental to safeguarding employee health.

In industrial applications, the efficiency of oil mist purifiers can have a transformative impact on productivity and operational costs. Studies indicate that companies utilizing these purifiers can reduce maintenance costs associated with machinery, as a cleaner environment decreases the likelihood of equipment wear and tear caused by oil deposition. Furthermore, the adoption of oil mist purifiers can lead to enhanced efficiency in energy consumption. A report from the American Society of Mechanical Engineers (ASME) highlights that, by minimizing excess oil in the air, these systems can improve the overall air flow and performance of ventilation systems, optimizing energy use and potentially lowering utility expenses. The integration of oil mist purifiers not only fosters a healthier workspace but also contributes to the bottom line in industrial operations.

Oil mist purifiers are essential in industrial applications, offering a wide range of advantages that contribute to both operational efficiency and environmental compliance. One of the key benefits is the significant reduction of airborne oil contaminants. By effectively capturing and filtering oil mist generated during machining processes, these purifiers ensure a cleaner workspace, which not only safeguards worker health but also enhances product quality by minimizing contamination risks.

Additionally, oil mist purifiers help in reducing maintenance costs for machinery. By removing fine oil particles from the air, these systems prevent the accumulation of oil residues on equipment and components. This leads to lower wear and tear, increased lifespan of machinery, and reduced frequency of maintenance checks. Moreover, the efficient management of oil mist can lead to improved energy efficiency, as clean equipment operates more effectively and consumes less power. Overall, the adoption of oil mist purifiers represents a strategic investment in the longevity and reliability of industrial operations.

Oil mist in industrial environments can pose severe health and safety risks to workers. According to a report from the Occupational Safety and Health Administration (OSHA), exposure to oil mist can lead to respiratory issues, skin irritations, and long-term health effects if not properly managed. By utilizing oil mist purifiers, companies can significantly mitigate these risks, creating a safer workplace. These purifiers effectively capture and filter out harmful oil droplets suspended in the air, reducing worker exposure to hazardous aerosols.

Moreover, a study published in the Journal of Occupational and Environmental Hygiene reveals that the implementation of oil mist purification systems can lead to a marked decrease in workplace accidents. Cleaner air quality not only enhances the comfort of workers but also boosts their productivity. Clearer airways enable workers to perform tasks more efficiently, thereby minimizing fatigue and errors often associated with poor air quality. As companies prioritize employee well-being, investing in oil mist purifiers becomes a crucial step toward ensuring a safe working environment and maintaining compliance with health regulations. This proactive approach not only safeguards employees but also enhances overall operational efficiency.

The integration of oil mist purifiers in industrial applications brings significant benefits, particularly in enhancing the longevity of machinery and equipment. Oil mist, when not effectively filtered, can lead to the accumulation of residues on parts, causing wear and tear that shortens the lifespan of critical components. By utilizing an oil mist purifier, industries can maintain a cleaner environment where equipment is less exposed to harmful particulates. This proactive approach not only reduces maintenance costs but also minimizes the need for premature replacements.

Tips for ensuring optimal performance of oil mist purifiers include regular maintenance checks and ensuring adequate airflow around the equipment. Implementing a schedule for cleaning the filters and inspecting the purifier system helps in identifying potential issues before they escalate. Additionally, educating employees about the importance of oil mist control can foster a culture of equipment care, ultimately contributing to longer machinery life.

Furthermore, investing in a high-quality oil mist purifying system can yield significant returns over time. The initial expenditure often pales in comparison to the savings gained from reduced downtime, lower maintenance costs, and extended equipment life. By making informed decisions about purification technology, companies can create a sustainable operational framework that prioritizes efficiency and longevity in equipment usage.

Oil mist purification systems are increasingly pivotal in enhancing environmental sustainability in industrial settings. These systems significantly reduce airborne oil mist, which can contribute to air pollution and health risks for workers. According to a report from the Occupational Safety and Health Administration (OSHA), prolonged exposure to oil mist can cause respiratory issues and skin irritation, highlighting the necessity for effective purification solutions.

Implementing an oil mist purification system not only protects employee health but also minimizes environmental impact. The U.S. Environmental Protection Agency (EPA) estimates that effective mist elimination can cut volatile organic compounds (VOCs) in industrial settings by up to 95%. This substantial reduction aligns with stringent regulatory standards, leading to lower emissions overall and contributing to cleaner air quality in surrounding communities.

Tips: Consider regularly monitoring your air quality and oil mist levels to assess the effectiveness of your purification system. Additionally, ensure that your maintenance routines are up to date to maximize the performance and longevity of the equipment. Adopting an oil mist purification system is more than a regulatory measure; it's a commitment to fostering a healthier and more sustainable industrial environment.

| Benefit | Description | Environmental Impact |

|---|---|---|

| Reduces Air Pollution | Removes harmful oil mists from the air, improving air quality. | Lowers worker exposure to toxic substances. |

| Enhances Workplace Safety | Minimizes slip hazards from oil accumulation on floors. | Reduces accidents and injury rates. |

| Lower Energy Consumption | Efficient purification leads to reduced need for HVAC systems. | Contributes to overall energy savings. |

| Extended Equipment Life | Keeps machinery free from harmful oil deposits. | Reduces waste and resources needed for replacements. |

| Improved Air Circulation | Enhances air quality by removing pollutants. | Promotes a healthier environment for workers. |

| Compliance with Environmental Regulations | Helps meet local and global emission standards. | Prevents fines and legal issues. |

| Cost Efficiency | Reduces overhead costs associated with cleaning and maintenance. | Optimizes resource utilization. |

| Boosts Worker Morale | Creates a cleaner and healthier work environment. | Promotes employee well-being. |

| Facilitates Recycling of Oil | Enables collection and reuse of oil mists. | Reduces environmental waste. |

| Increases Production Efficiency | Minimizes downtime related to air quality issues. | Enhances overall manufacturing sustainability. |