- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

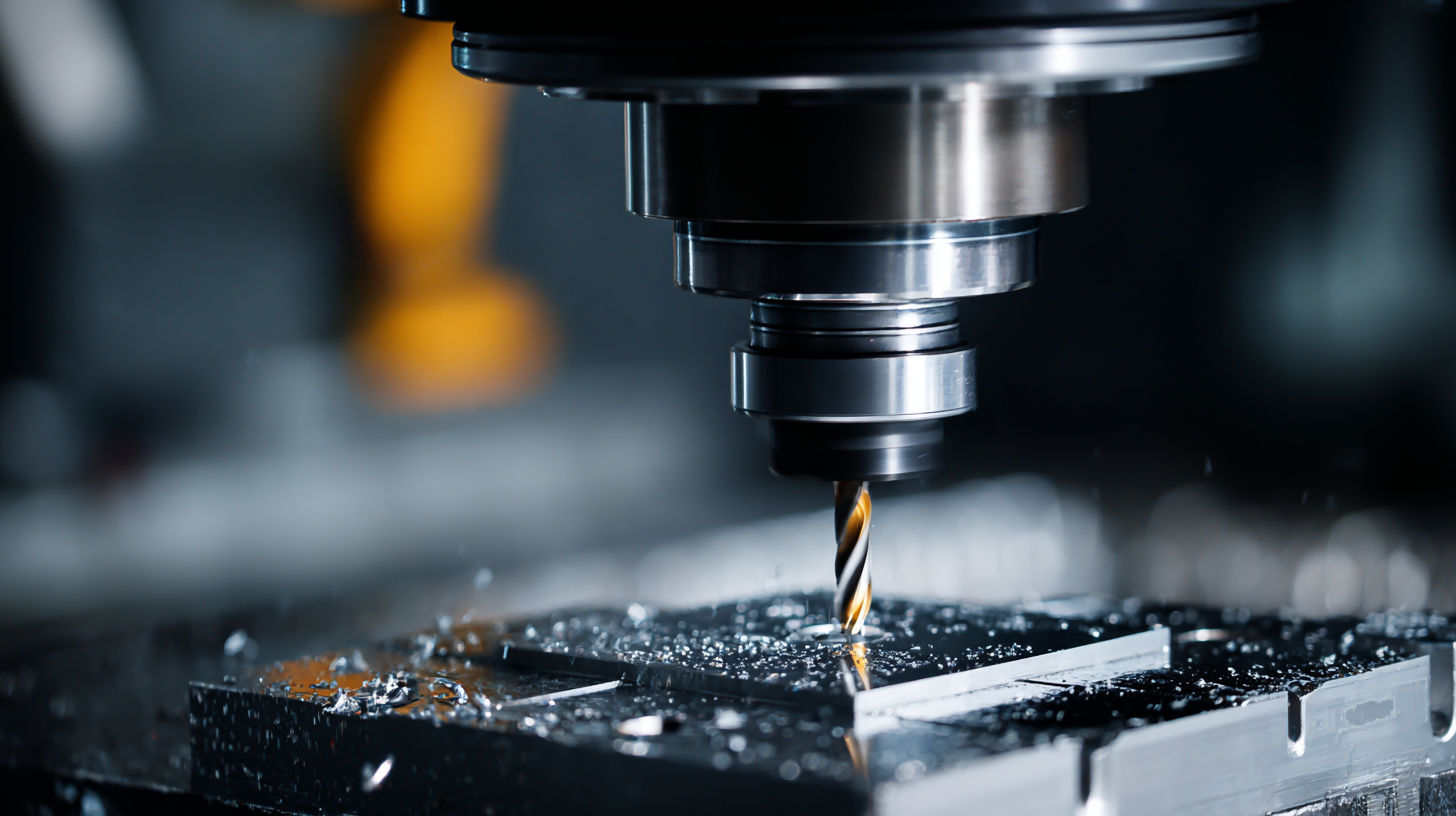

In the ever-evolving landscape of modern manufacturing, the integration of advanced technologies to enhance efficiency is paramount. One of the key innovations contributing to this transformation is the Angular Head for VMC (Vertical Machining Centers). This specialized attachment allows manufacturers to tackle complex geometries and achieve precision machining that would be challenging with standard setups.

By providing the ability to pivot and tilt workpieces, the Angular Head for VMC enables versatile operations that significantly reduce cycle time and optimize workflow. As industries increasingly demand higher productivity and versatility, understanding the importance and functionality of Angular Heads becomes essential for manufacturers aiming to stay competitive in a rapidly changing market.

This article will explore the role of Angular Heads in modern manufacturing, highlighting their benefits and applications that lead to enhanced operational efficiency.

Angular heads are becoming increasingly vital in vertical machining centers (VMC) as manufacturers seek to enhance productivity and precision. By allowing for angular adjustments, these heads enable operators to machine complex geometries and difficult-to-reach surfaces without the need for cumbersome setups. This versatility not only streamlines the manufacturing process but also significantly reduces the cycle time, as multiple operations can be performed in a single setup.

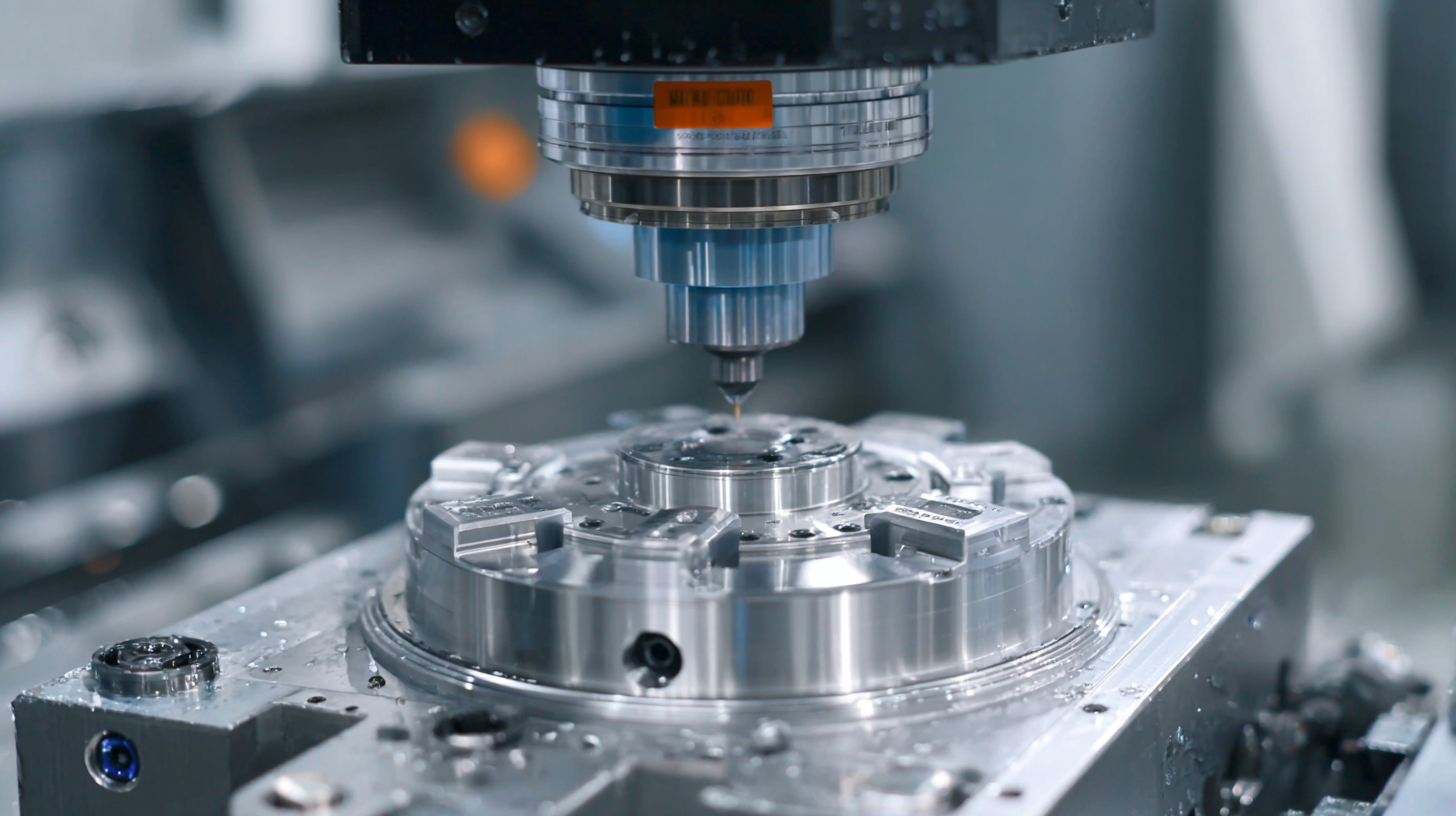

Another notable benefit of using angular heads in VMC is the improvement in tool life and product quality. The ability to adjust the angle enables more optimal cutting conditions, which can lead to lower tool wear and reduced scrap rates. Additionally, it facilitates the machining of intricate features that are essential in cutting-edge industries, such as aerospace and automotive manufacturing. As a result, adopting angular heads in VMC not only optimizes operational efficiency but also supports higher standards of quality and innovation in modern manufacturing practices.

In modern manufacturing, selecting the right angular head can significantly enhance the efficiency of vertical machining centers (VMCs). According to a study by the Association for Manufacturing Technology (AMT), approximately 40% of machining time can be optimized through the use of angular heads, which allow manufacturers to achieve complex angles and contours without the need for multiple setups. This not only reduces cycle times but also minimizes tooling costs and enhances overall operational productivity.

When choosing an angular head, manufacturers should consider several key factors. First, the range of angles offered by the angular head is crucial; many high-quality models provide functionality from 0 to 90 degrees. Additionally, the attachment compatibility with existing VMCs plays a vital role in ensuring seamless integration into production lines. A report from the National Tooling and Machining Association (NTMA) states that nearly 30% of production downtime stems from improper tooling equipment, highlighting the importance of making informed choices regarding angular head selection. Lastly, the precision and repeatability of the angular head must align with the specific demands of manufacturing applications, as even minor inaccuracies can lead to significant waste and inefficiency.

| Dimension | Standard Options | Typical Applications | Key Considerations |

|---|---|---|---|

| Angle Range | 0° - 90° | Milling Complex Shapes | Ensure Compatibility with VMC |

| Max RPM | 10,000 RPM | High-Speed Machining | Check Gear Ratio for Desired Power |

| Weight | 5 - 20 kg | Heavy Component Machining | Balance for Stability |

| Tool Holder Compatibility | ISO, BT, HSK | Versatile Tooling Needs | Specify Tool Changes |

| Cooling Options | Air, Flood | Heat Dissipation | Select Based on Material |

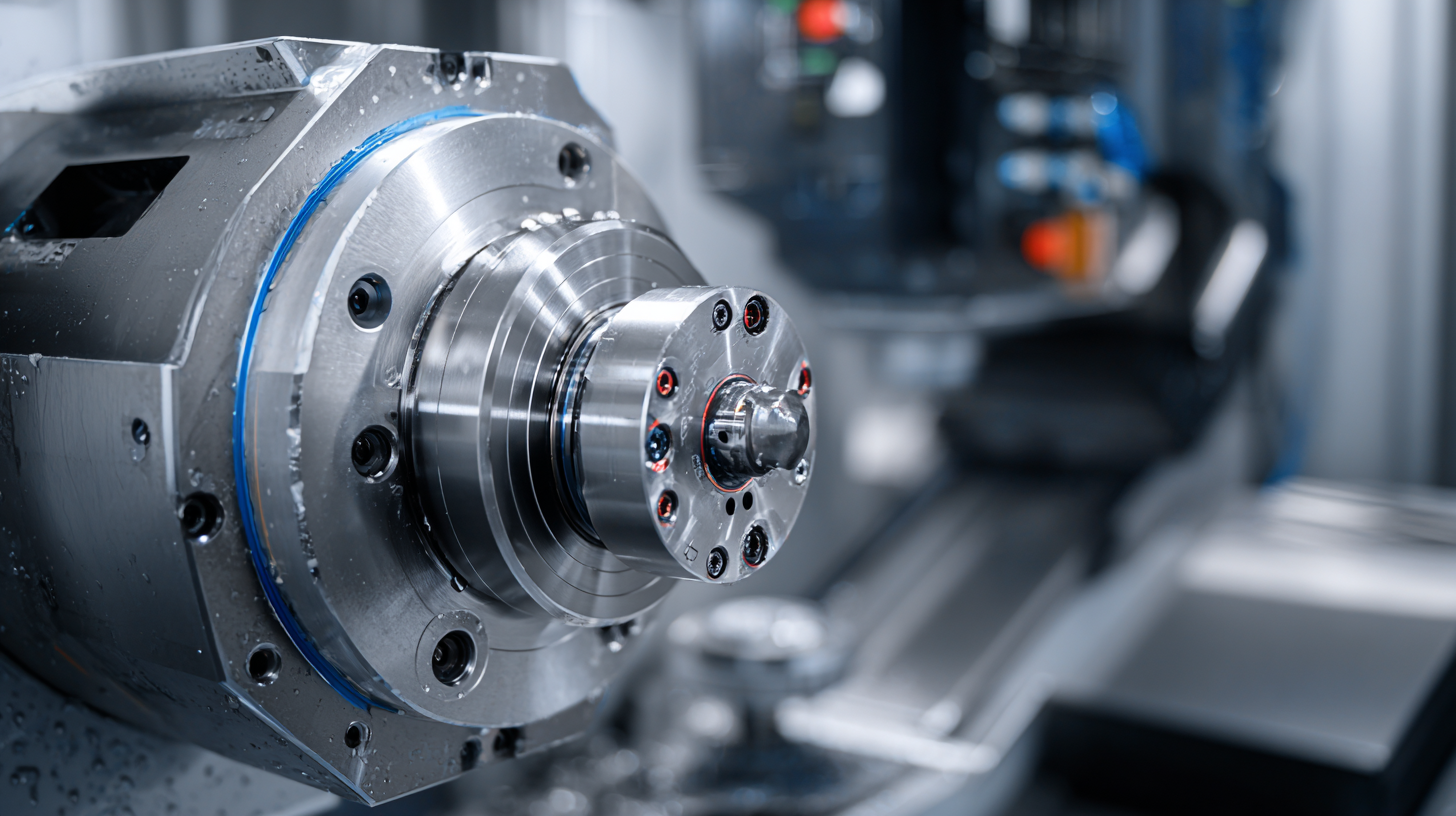

In modern manufacturing, the efficiency of machining processes can be significantly enhanced through the use of advanced angular head designs. These specialized attachments are engineered to enable more versatile positioning of cutting tools, allowing for complex machining operations that would be challenging with traditional setups. By maximizing the variety of angles and orientations available during the machining process, angular heads significantly reduce setup times and improve overall productivity, thereby addressing the demands of contemporary manufacturing environments.

Similar to advancements in sustainable technologies like vortex turbines, which optimize blade geometry and flow configuration for energy generation, angular heads harness optimization principles to elevate machining efficiency. The meticulous design of angular heads not only improves tool access to intricate workpieces but also fosters better tool life and finish quality. As manufacturers strive for greater productivity and sustainability, the integration of advanced angular head technologies becomes a crucial factor in realizing these goals, ultimately leading to a more efficient and competitive manufacturing landscape.

Integrating angular heads into vertical machining centers (VMCs) can significantly enhance machining efficiency and flexibility. To effectively incorporate these specialized attachments, it is essential to begin with a thorough assessment of the specific manufacturing needs. Understanding the types of materials being machined and the complexity of the geometries involved will guide the selection of the appropriate angular head. This alignment ensures that the equipment can handle the required tasks without compromising performance or quality.

Moreover, training personnel on the operation and maintenance of angular heads is crucial. Operators must be familiar with the setup procedures and programming adjustments necessary for optimal performance. Regular maintenance routines should also be established, focusing on the calibration and inspection of both the angular heads and the VMC itself. By fostering a culture of continuous improvement and education, manufacturers can fully leverage the capabilities of angular heads, resulting in increased productivity and reduced cycle times in their VMC operations.

The landscape of modern manufacturing is rapidly evolving, with angular head technology at the forefront of this transformation. These devices, which allow for multi-faceted machining and greater versatility, are becoming increasingly essential in optimizing efficiency on vertical machining centers (VMCs). Future trends indicate that advancements in materials and design will enhance the durability and performance of angular heads, allowing manufacturers to tackle more complex geometries with precision and speed.

Moreover, as Industry 4.0 continues to influence manufacturing, the integration of smart technologies with angular heads is expected to play a crucial role in predictive maintenance and data analytics. By utilizing sensors and IoT connectivity, manufacturers can monitor the performance of angular heads in real-time, thus minimizing downtime and maximizing productivity. The synergy between angular head technology and smart manufacturing will likely result in unprecedented efficiency gains, enabling companies to adapt swiftly to changing market demands while maintaining high-quality output.