- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

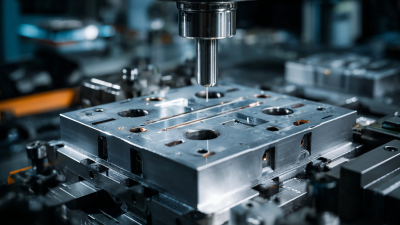

In the realm of precision machining, the efficiency and effectiveness of machining processes are paramount. One innovative tool that has emerged to enhance these processes is the Angle Milling Head. This attachment is designed to hold cutting tools at various angles, allowing for more versatile machining capabilities compared to traditional setups. As manufacturers strive to improve productivity and operational flexibility, understanding the function and advantages of the Angle Milling Head becomes essential.

The Angle Milling Head facilitates access to difficult-to-reach surfaces and intricately designed components, making it invaluable for complex machining tasks. By allowing for angular cutting operations, it not only reduces setup times but also minimizes the need for multiple setups, which can lead to greater accuracy and consistency in finished products. Moreover, the ability to manipulate the angle of the tool can significantly enhance the quality of the machined surface, giving manufacturers a competitive edge in quality control.

Ultimately, incorporating the Angle Milling Head into machining processes is a strategic move that can lead to improved workflow efficiency and reduced production costs. As companies look to innovate and streamline their operations, understanding the capabilities and benefits of this specialized tool will be crucial in enhancing their overall machining performance and meeting the ever-evolving demands of the industry.

An angle milling head is a specialized attachment used in milling machines that allows for the cutting tool to be positioned at an angle to the workpiece. This multifunctional tool plays a crucial role in machining operations by providing increased versatility and efficiency. By enabling machining at various angles, it facilitates the production of complex shapes and contours that would otherwise be challenging to achieve with standard setups. This capability allows manufacturers to perform tasks such as beveling, groove cutting, and edge machining without the need for multiple setups.

The primary function of an angle milling head lies in its ability to enhance the precision of machining operations. By optimizing the angle at which the cutting tool approaches the material, it minimizes the force required, resulting in improved tool life and surface finish. Additionally, the use of an angle milling head reduces the need for manual adjustments and fixtures, thus streamlining the workflow and reducing the overall machining time. This efficiency can lead to cost savings and higher productivity, making it an invaluable tool in modern manufacturing processes.

| Feature | Description | Benefits |

|---|---|---|

| Versatility | Allows for cutting in various angles and surfaces. | Increases flexibility in machining operations. |

| Precision | Provides accurate angular cuts and finished surfaces. | Enhances the quality of machined components. |

| Productivity | Facilitates faster machining by reducing setups. | Decreases overall machining time. |

| Tooling Cost | Utilizes specialized tooling for specific angles. | Reduces need for multiple tools and setups. |

| User-Friendliness | Designed for easy setup and operation. | Minimizes training time for operators. |

Angle milling heads are specialized attachments that enhance the versatility of milling machines by allowing for angular cuts and more complex geometries. These heads are designed with features that enable precise adjustments to the cutting angle, often ranging between 0 to 90 degrees. This capability opens up a wider range of machining tasks, such as creating bevels, flat surfaces, and other intricate profiles that would be difficult or impossible to achieve with standard milling operations.

Key components of an angle milling head include the turning mechanism, which allows for angle adjustments, and the cutting tool arbor, which securely holds the milling tool in place. The design often incorporates a rigid housing to minimize vibrations and ensure stability during machining. Additionally, some angle milling heads feature quick-release systems for faster tool changes, enhancing overall efficiency on the shop floor.

**Tips:** To maximize the effectiveness of your angle milling head, ensure that it is properly calibrated for the specific angles you are working with. Regular maintenance, such as checking for wear on the cutting edges and the tightness of the arbor, will prolong the life of the head and maintain machining accuracy. Furthermore, when changing angles, always make gradual adjustments to prevent abrupt shifts that could lead to tool breakage or damage to the workpiece.

Angle milling heads are specialized tools that significantly enhance the capabilities of milling machines. By allowing operators to cut at various angles, these heads facilitate more complex machining processes that would be challenging or impossible with standard milling setups. This adaptability enables manufacturers to create intricate components with improved accuracy, ultimately leading to better product quality.

One of the primary advantages of using angle milling heads is their ability to increase productivity. With the capacity to perform numerous operations without the need for repositioning the workpiece, manufacturers can save valuable time during production. Additionally, the enhanced versatility offered by angle milling heads reduces the need for multiple machines, streamlining the workflow and conserving resources. Furthermore, by achieving precise angular cuts, these tools minimize material waste, promoting a more efficient manufacturing process. Overall, the integration of angle milling heads into machining operations offers significant benefits that contribute to enhanced efficiency and product quality in the manufacturing sector.

Angle milling heads are versatile tools that significantly enhance machining processes across various industries. One of the key applications is in the aerospace sector, where precision is paramount. These heads allow for the machining of complex geometries and angled features in aircraft components, ensuring that every part meets the stringent standards required for safety and performance. The ability to precisely mill angles improves the efficiency of the manufacturing process, reducing the number of setups and cycles needed to complete intricate designs.

In the automotive industry, angle milling heads contribute to the production of engine components, transmission housings, and other critical parts that require precise angle cuts and features. Their ability to process materials at various angles simultaneously streamlines production and improves overall accuracy, which is vital in high-volume manufacturing scenarios. Moreover, angle milling is also beneficial in the construction and metalworking industries, where fabricating components that fit together seamlessly is essential for structural integrity. By incorporating angle milling heads, manufacturers can enhance their capabilities and achieve better results in terms of both productivity and quality.

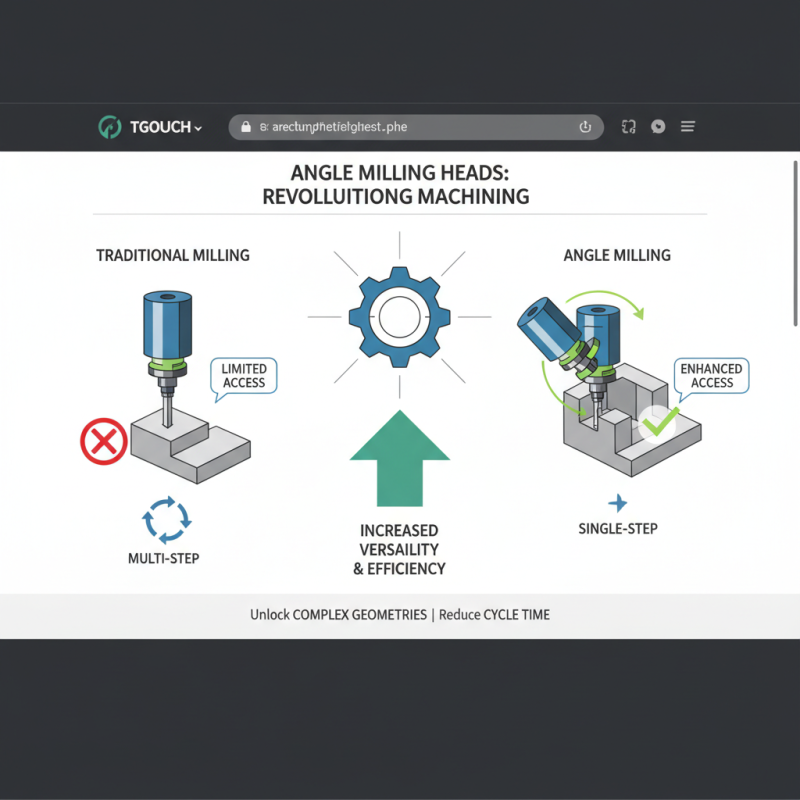

Angle milling heads have transformed the landscape of machining by offering distinct advantages over traditional milling methods. Unlike conventional milling heads that operate primarily in a vertical or horizontal plane, angle milling heads enable operators to change the cutting angle, enhancing the versatility of machining tasks. This capability allows for more complex part geometries and improves access to challenging areas of a workpiece, which can significantly reduce the time and effort required for multi-step operations.

When comparing angle milling heads to traditional methods, one notable difference is the efficiency in machining time and setup. Traditional milling often requires frequent reorientation of the workpiece or multiple passes to achieve the desired angles and surfaces. In contrast, an angle milling head allows for simultaneous machining of both flat and angled surfaces, streamlining the production process. Furthermore, by reducing the number of setups, operators can minimize errors and improve overall quality, ensuring that the final products meet precise specifications with less manual intervention. This not only boosts productivity but also contributes to a more efficient workflow in any machining environment.