- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

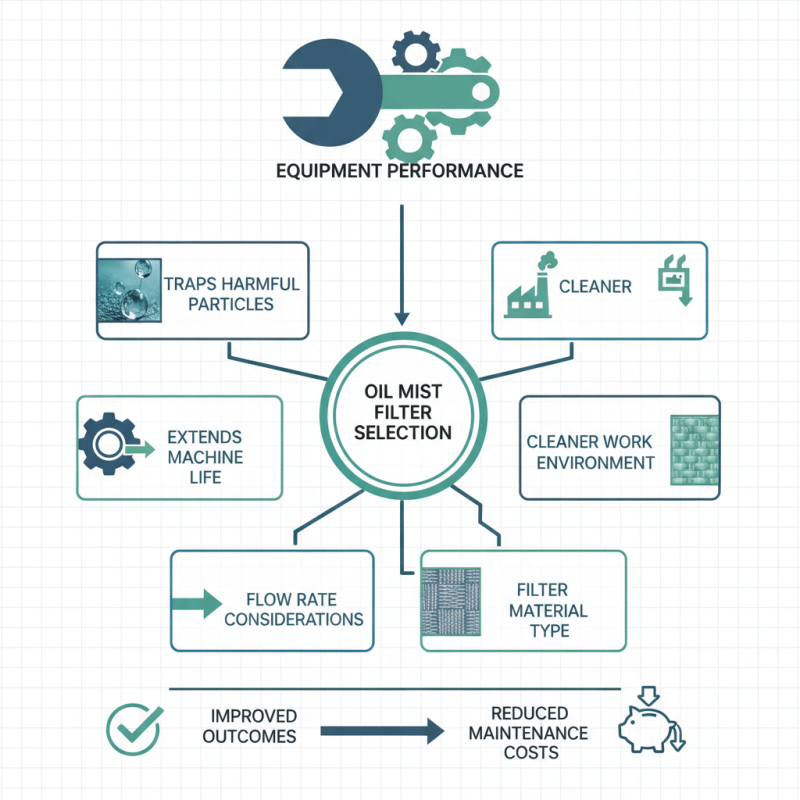

When selecting an oil mist filter, understanding the options is crucial. The right oil mist filter buy can significantly enhance equipment performance. These filters trap harmful oil particles, extending machine life and ensuring cleaner work environments.

Choosing an oil mist filter requires careful consideration. Many brands claim to offer the best solutions, yet not all deliver as promised. For example, some filters may not capture smaller particles effectively. This imperfection can lead to increased machine wear and maintenance costs.

It's essential to evaluate specific needs before making a purchase. Not every oil mist filter suits every application. Factors like flow rate and filter material play critical roles in effectiveness. Understanding these elements helps in making a wise decision. Reflecting on these considerations can lead to improved outcomes in the long run.

Oil mist filters are essential in various industrial settings. They trap airborne oil particles, improving air quality. These filters come in different types, each serving a specific function. Some filters use mechanical means, while others rely on electrostatic forces. Each type has its own merits and drawbacks. Understanding these differences can help you make an informed choice.

Mechanical filters rely on physical barriers to capture oil mist. They can be effective, but they require regular maintenance to avoid clogging. Electrostatic filters attract oil particles using electrical charges. These are often more efficient but can be costly to maintain. When selecting a filter, consider the environment in which it will be used. Will it face high humidity or extreme temperatures? Such factors can impact performance.

Many users overlook the importance of filter placement. Incorrect positioning can limit effectiveness. A poorly placed filter may fail to capture oil mist adequately. Regularly checking filter efficiency is also crucial. Signs of reduced performance should prompt immediate action. Ultimately, understanding the functions and types of oil mist filters can lead to better decisions.

When selecting an oil mist filter, several key features are essential. Efficiency is paramount. Look for filters with a high removal efficiency rate. Data indicates that top filters capture over 99% of oil mist. This is crucial for maintaining air quality and worker safety.

Consider the filter's capacity. Some models can handle higher volumes of mist, which is vital for busy industrial settings. According to industry reports, under-sizing a filter can increase maintenance costs by 30%. That’s a significant consideration for budget-conscious operations.

Ease of maintenance matters too. Frequent clogging leads to increased downtime. Filters designed for easy cleaning and replacement can save time. Industry experts highlight that manual cleaning can reduce filter lifespan by 50%. Finding a balance between operational efficiency and maintenance needs is not easy. Investing in a quality oil mist filter can yield long-term benefits, but it’s essential to evaluate your specific needs carefully.

When selecting an oil mist filter in 2026, knowing the top brands and models can guide your decision. The market is flooded with options. Yet, only a few stand out due to their efficiency and reliability. Reports suggest that effective oil mist filtration can reduce airborne contaminants by over 90%. Such performance is crucial in industries where air quality directly impacts worker safety.

Models that meet stringent filtration standards often feature advanced materials. These filters can handle high volumes of mist while maintaining durability. Studies indicate that filters with a larger surface area provide better longevity and require less frequent replacements. In some cases, maintenance can drop by 30% with the right choice.

However, not all products deliver as promised. Some filters may claim to capture minute particles but fall short in practice. User reviews often highlight frustration over unexpected downtimes or inadequate performance. It's vital to weigh these aspects when considering options. Lastly, always look for filters that offer real-world data on their performance in similar environments. Knowledge is key to making an informed choice.

| Filter Model | Efficiency (%) | Air Flow Rate (m³/h) | Filter Media Type | Maintenance Interval (Months) | Average Price ($) |

|---|---|---|---|---|---|

| Model A | 99 | 600 | HEPA | 12 | 350 |

| Model B | 95 | 500 | Synthetic | 6 | 250 |

| Model C | 98 | 800 | Activated Carbon | 9 | 400 |

| Model D | 97 | 550 | Metal Mesh | 15 | 300 |

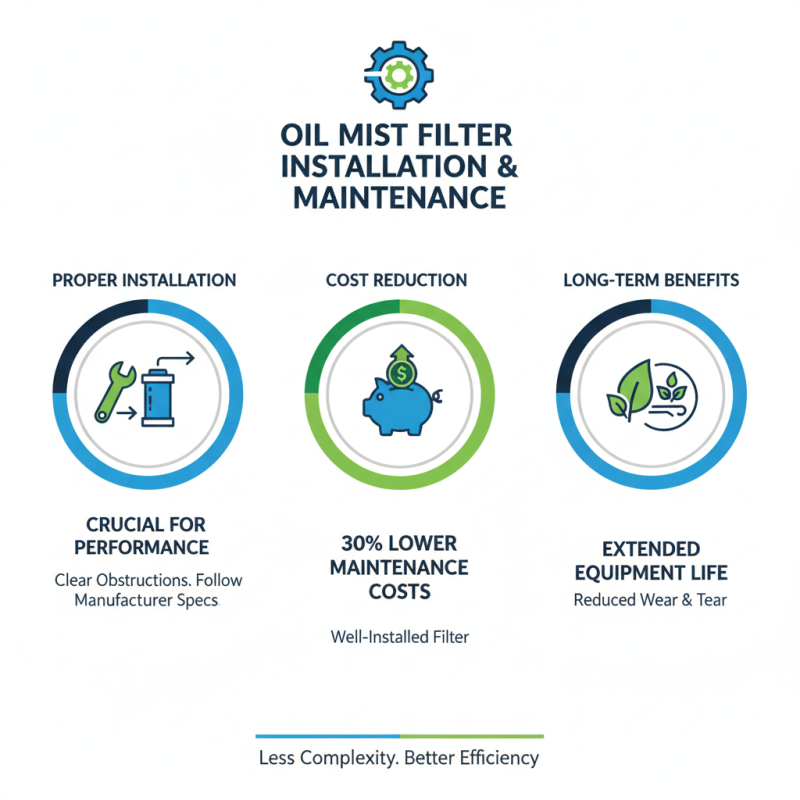

Installing and maintaining an oil mist filter can be complex. Proper installation is crucial for optimal performance. Research indicates that a well-installed filter can reduce maintenance costs by 30%. Ensure that the installation area is free from obstructions. Follow the manufacturer's specifications closely.

Regular maintenance is necessary to keep the filter functioning efficiently. It is advised to inspect the filter every month. Depending on usage, you might need to replace filter media more often than expected. For instance, filters in high-saturation areas may clog within just a few weeks. Ignoring maintenance can lead to reduced airflow and increased operational costs.

Monitoring the system during operation is also important. Pay attention to any unusual noises or decreased efficiency. A drop in performance often indicates that it’s time to clean or replace components. Neglecting these signs can cause larger mechanical issues down the line. According to industry studies, over 50% of failures stem from inadequate maintenance practices. Stay vigilant for the best results.

Oil mist filters play a crucial role in maintaining clean operations in industrial settings. However, users often face common issues.

One frequent problem is reduced efficiency over time. Filters can become clogged with oil and dust. This leads to increased maintenance costs. Regular checks are essential. Cleaning or replacing filters can restore functionality.

Another issue is the risk of oil mist leaks. These leaks can occur due to poor installation. A loose fitting may cause unwanted emissions, leading to hazardous conditions. Proper installation is vital. It's wise to consult with experts during setup to avoid future complications.

Users also report excessive noise from oil mist filters. This can be distracting and frustrating. Sometimes, noise indicates mechanical failure or misalignment. Regular maintenance checks can identify issues early. It's beneficial to address these concerns promptly, ensuring the longevity of the filter system.