- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

In the world of industrial manufacturing, a Compressed Air System is vital. This system powers various tools, influences productivity, and affects efficiency. According to a recent report, nearly 70% of manufacturing facilities rely on compressed air, highlighting its significance.

However, many companies overlook the importance of selecting the right system features. A poorly designed Compressed Air System can lead to energy losses of up to 30%. This inefficiency not only impacts operational costs but also contributes to environmental concerns. The industry is under increasing pressure to adopt sustainable practices while maintaining productivity.

Understanding the proper features and benefits of a Compressed Air System is crucial. It can lead to enhanced performance, reduced waste, and lower energy bills. Companies must reflect on their systems' efficiency regularly. This awareness can spark necessary improvements and innovations in compressed air technology.

Compressed air systems are essential in various industrial applications. They provide power for tools, assist in material handling, and support production lines. A well-designed compressed air system can enhance efficiency and reduce operational costs. However, many facilities overlook maintenance. This can lead to significant energy waste and system inefficiencies.

In 2026, the focus is on improving system features. Users demand reliability and energy efficiency. Smart monitoring technologies can help identify leaks and inefficiencies in real-time. Installing variable speed drives can optimize energy consumption, especially under fluctuating demand. Proper storage solutions, like air receivers, minimize pressure drops during peak usage. Yet, not all systems incorporate these advancements. Some still rely on outdated models, which hampers productivity.

Moreover, the integration of advanced filtration systems is crucial. They ensure air quality is maintained for sensitive applications. Contaminated air can damage equipment and reduce product quality. Still, many companies neglect this aspect. There is a need for regular inspections and employee training on system operation. Investing in these areas can yield substantial returns over time.

| Feature | Description | Benefits |

|---|---|---|

| Variable Speed Drives (VSD) | Adjusts motor speed based on air demand. | Improves energy efficiency, reduces operational costs. |

| Energy Recovery Systems | Recovers waste energy from compressed air systems. | Enhances overall system efficiency, lowers energy costs. |

| Integrated Controls | Centralized control for monitoring and operation. | Increases system reliability, easy management. |

| Low Noise Operation | Designed to minimize operational noise levels. | Improves workplace safety and comfort. |

| Advanced Filtration Systems | Removes contaminants from compressed air. | Ensures product quality and extends equipment life. |

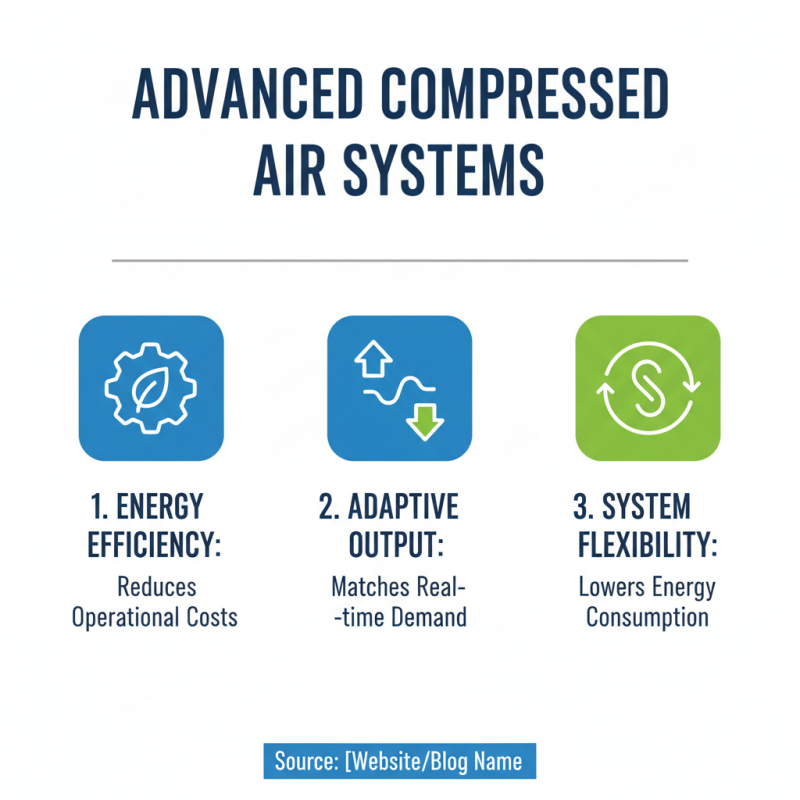

When looking for advanced compressed air systems, certain features stand out. Energy efficiency is key. Systems that can adapt their output based on real-time demand are crucial. This flexibility allows for lower energy consumption, which can significantly reduce operational costs over time.

Monitoring capability is another feature to consider. Systems equipped with real-time monitoring tools can provide insights into performance and maintenance needs. Such data helps in making informed decisions. However, some users may find these systems complex at first. Training staff is essential for effective usage.

Reliability is also vital. A system that fails frequently can disrupt production. Look for features that enhance durability, such as robust materials and advanced filtration. You'll want a design that minimizes downtime and is easy to service. While many systems claim high reliability, actual performance can vary. Regular evaluations and feedback can sometimes reveal hidden weaknesses.

Upgrading to modern compressed air systems can bring significant benefits. These systems often provide improved energy efficiency. Traditional systems may waste up to 30% of energy. New technologies can reduce this waste dramatically. The initial costs might seem high, but savings accumulate over time.

A cost-benefit analysis shows clear advantages. Enhanced efficiency leads to lower utility bills. Additionally, maintenance costs may drop with newer systems. Older equipment often requires frequent repairs. In some cases, unexpected breakdowns can halt production.

Businesses must consider the initial investment versus long-term gains. While the change may seem daunting, the return on investment can be significant. Observing a neighbor's success could inspire action. Evaluating current needs against future requirements is essential. Decisions made today shape tomorrow’s productivity.

Energy efficiency is crucial for maintaining high-performance compressed air systems. An efficient system not only saves power but also lowers operational costs. Reducing energy consumption can significantly impact the overall productivity of manufacturing processes. When energy costs rise, the need for efficiency becomes even more pressing.

One practical tip for improving efficiency is to regularly inspect your system for leaks. Small leaks can lead to significant energy loss over time. Even a tiny hole can waste a large volume of compressed air. Conducting routine maintenance can prevent costly repairs and inefficiencies.

Investing in high-quality components can enhance the energy efficiency of your compressed air system. While this may require an upfront cost, the long-term savings can be substantial. Remember, a well-optimized system is less likely to break down unexpectedly.

Don't overlook the importance of training operators to manage the system effectively. Ensuring everyone understands proper usage can reduce unnecessary energy waste. However, it’s important to understand that even the best systems require adjustments over time. Observing performance regularly can help identify when updates are necessary.

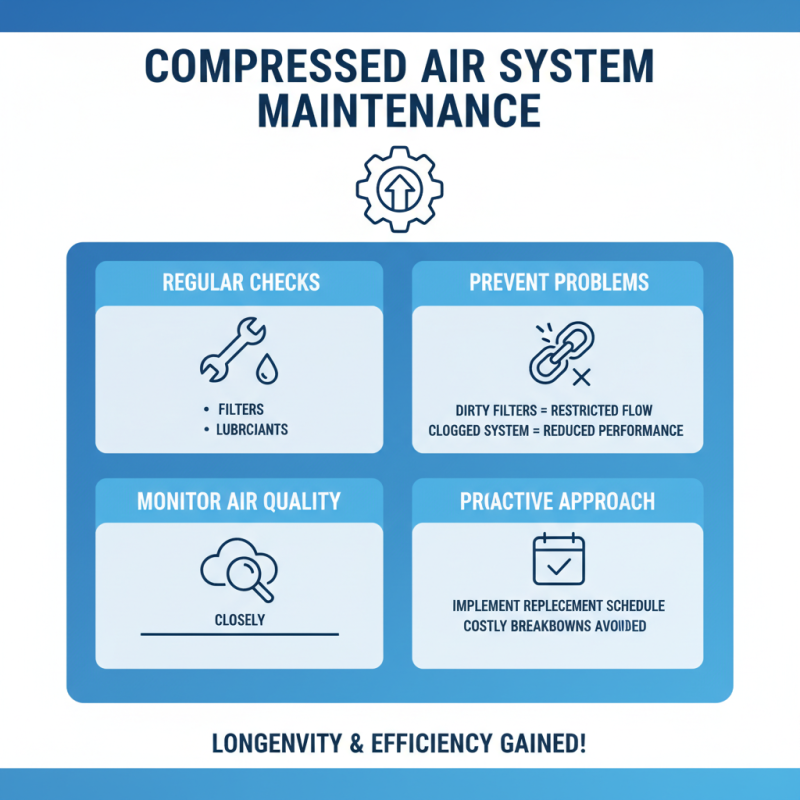

Maintaining a compressed air system is crucial for its longevity and efficiency. Regular checks on filters and lubricants can prevent costly breakdowns. Dirty filters can cause flow restrictions. A clogged system reduces performance. Monitor air quality closely. Consider implementing a schedule for replacements. It may seem tedious, but proactive maintenance is beneficial.

Additionally, inspect hoses and connections for wear. Leaks can significantly impact your system’s efficiency. A small leak, often overlooked, can waste a lot of energy. Use ultrasonic leak detectors to find hidden issues. Don’t underestimate the power of inspection. It can save you money in the long run.

Another aspect is the importance of training for personnel. They should understand operation basics and maintenance protocols. Lack of knowledge can lead to mishaps. Ensure they know the right procedures. Mistakes happen, but clarity can reduce them. Remember, a well-maintained system achieves better performance and reliability over time. Reflect on existing practices for continuous improvement.