- sales@bjbod.com

- Mon - Sat at 7:00AM to 9:00PM

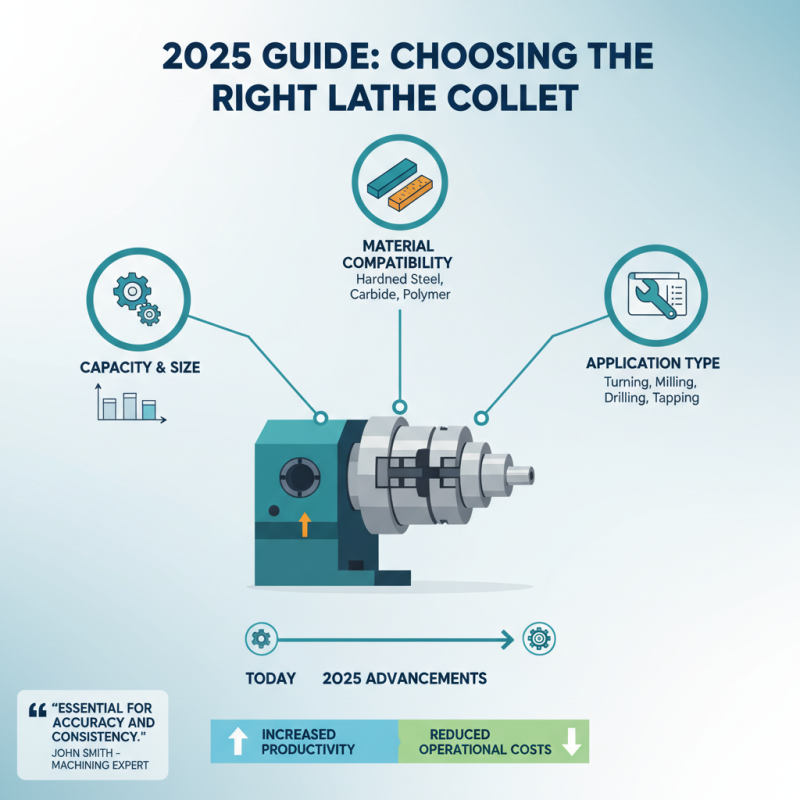

In the world of machining, the choice of the right collet for lathe applications can significantly impact efficiency and precision. As noted by machining expert John Smith, “The right collet is not just an accessory; it’s essential for achieving accuracy and consistency in every project.” In 2025, the advancements in collet design and materials mean that machinists now have a broader array of options than ever before. Selecting the right collet for lathe operations is therefore crucial not only for optimal performance but also for enhancing the overall lifespan of the equipment.

Understanding the various types and specifications of collets available can be complex, which is why this guide aims to simplify the selection process. Factors such as collet capacity, material compatibility, and the intended application all play critical roles in determining the best fit. With increased competition and customer demands, adopting the right collet for lathe setups can lead to improved productivity and reduced operational costs. This comprehensive guide will provide insights and practical tips to help operators make informed choices that suit their specific needs in the machining industry.

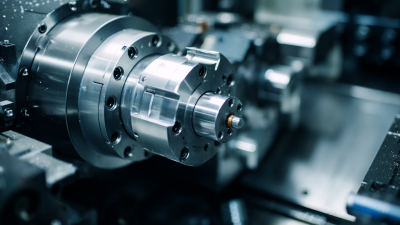

Lathe collets play a crucial role in the machining process, primarily serving as a tool holder that accurately secures the workpiece. Unlike conventional chucks, which can only grasp workpieces of a specific size, collets can accommodate various diameters, offering versatility and precision. The primary function of a collet is to convey clamping force evenly around the circumference of the workpiece, which minimizes vibrations and enhances the stability of the machining operation. This is especially important when performing intricate cuts and ensuring high-quality finishes.

Understanding the fundamental types of collets available can significantly impact the efficiency of your lathe machine. Collets come in various designs—including spring collets, where a tapered sleeve compresses to grip the workpiece, and auto-closing collets, which adjust themselves for a tighter hold. Each type offers distinct advantages depending on the material being machined and the precision required. Knowledge of these functions will enable users to select the right collet that aligns with their specific machining tasks, ultimately leading to improved productivity and reduced wear on both the machine and the tooling.

When selecting the right collet for your lathe machine, understanding the various types available is crucial for achieving optimal performance. Collets are precision workholding devices that securely grip the workpiece, and they come in several forms, each designed for specific applications. The most common types include ER collets, which are versatile and ideal for holding tools with varying shank sizes thanks to their wide range of sizes. Another popular choice is the 5C collet, known for its robust design and ability to handle larger workpieces, making it well-suited for heavier machining tasks.

In addition to ER and 5C collets, machinists might consider other variants, such as the R8 collet, often used in milling applications but compatible with certain lathe setups. Selecting the right collet involves assessing the diameter of the workpiece, the type of machining operation planned, and the required precision. Factors such as material type and desired surface finish also play a significant role in this decision-making process. By carefully evaluating these elements, operators can ensure that they choose a collet that enhances both the efficiency and accuracy of their lathe operations.

Choosing the right collet for your lathe machine is crucial for ensuring optimal performance and precision in machining operations. One of the primary considerations is the material of the collet itself. Collets are often made from materials such as steel, aluminum, or even specialized alloys. According to a 2023 industry report by the International Association of Machinists, steel collets are favored for their high tensile strength and durability, making them suitable for heavy-duty applications. In contrast, aluminum collets are lighter and assist in reducing spindle load, which can be beneficial for high-speed operations. Understanding the material properties is essential, as it directly influences not just the performance, but also the longevity of your machining setup.

In addition to material, the size of the collet is another critical factor to consider. The collet's inner diameter should match the size of the tool shank to ensure a snug fit and minimize vibration during operation. A survey published in the Journal of Manufacturing Science showed that improper sizing can lead to a decrease in machining accuracy by up to 30%. Moreover, incorrect collet size can result in faster wear and increased maintenance costs, as stressed tools may break more easily. Utilizing precise measurement tools can help operators select the right collet size, ultimately leading to enhanced operational efficiency and improved product quality in machining processes.

When selecting the right collet for your lathe machine, several key features should be taken into account to optimize performance and ensure precision in your machining tasks. First, the collet size compatibility with the workpiece and the machine spindle is crucial. Industry reports indicate that over 60% of machining errors are attributed to improper collet sizing, leading to inaccuracies and wasted material. Thus, it's essential to match the collet's specifications precisely with those of the spindle and tool shank.

Another significant feature to consider is the type of collet mechanism. Options range from standard spring collets to precision collets, each offering distinct advantages based on the application. Precision collets, for instance, are typically utilized in high-accuracy operations, featuring tighter tolerances of less than 0.001 inches, as supported by data from the National Institute of Standards and Technology. Furthermore, users should assess the collet's material construction; high-quality steel or alloy materials can enhance durability and maintain performance under adverse working conditions, which is vital for long-term operational efficiency.

Lastly, it’s essential to evaluate the ease of installation and clamping mechanism. A user-friendly design can significantly reduce setup time, which is a critical factor in a competitive machining environment where efficiency is paramount. According to a survey conducted by the Precision Machined Products Association, improved setup times can lead to a reduction in labor costs by as much as 20%, underscoring the importance of choosing a collet that simplifies this process.

Proper installation and maintenance of lathe collets are crucial for ensuring optimal performance and accuracy in machining processes. When installing a collet, it is important to clean the collet and the spindle to remove any debris or oil that may hinder the grip. Always ensure that the collet is aligned properly within the spindle, as misalignment can lead to uneven clamping and cause workpieces to slip during operation. A snug fit is essential, so tighten the collet according to the manufacturer's specifications to prevent loosening under pressure.

Regular maintenance is equally important to prolong the lifespan of your lathe collets. Inspect collets frequently for signs of wear, such as cracks or deformities, which may compromise their functionality. It's a good practice to lubricate the collets gently to minimize friction and prolong their operational life. Additionally, storing collets in a clean, dry place helps to prevent corrosion and damage. By following these installation and maintenance tips, you can ensure that your lathe collets function efficiently and maintain precision in your machining tasks.